Novel unbonded post-tensioning prestress uplift pile structure

A non-bonded, uplift-resistant pile technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of easy corrosion of uplift piles and functional failure of uplift piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

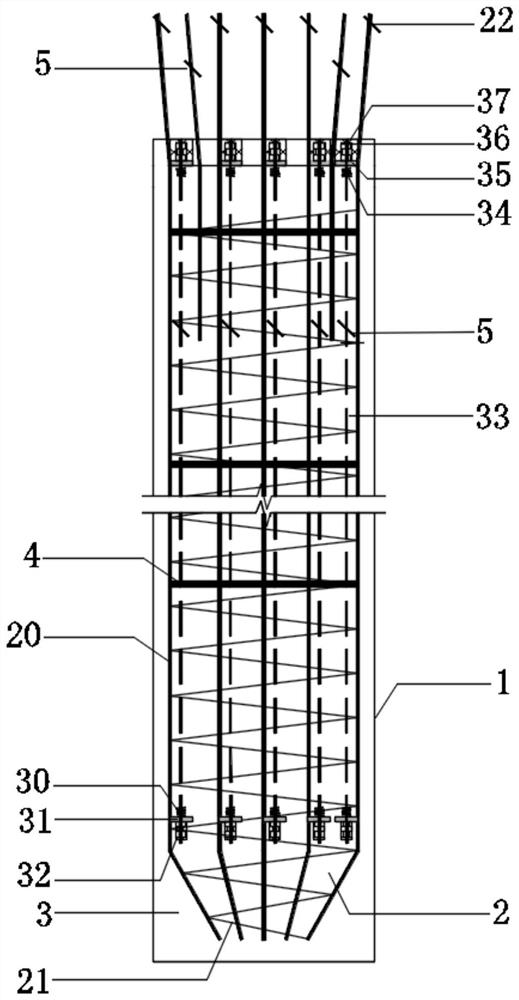

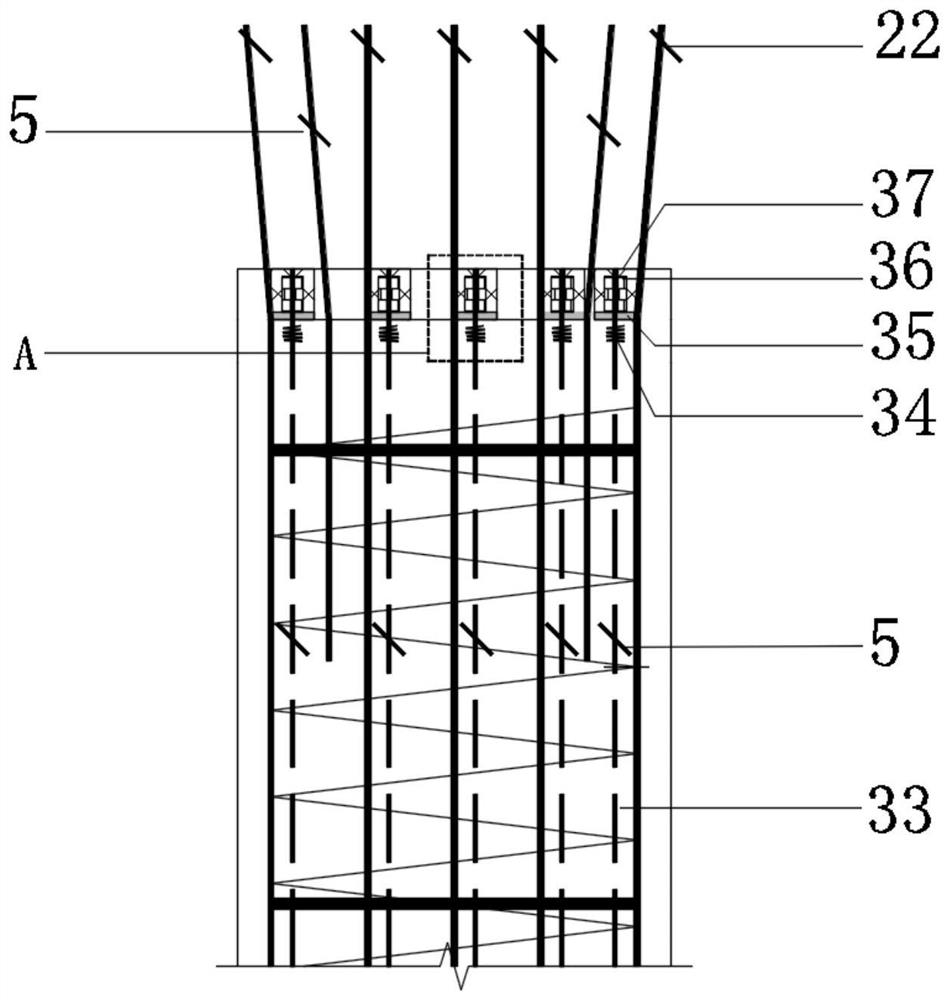

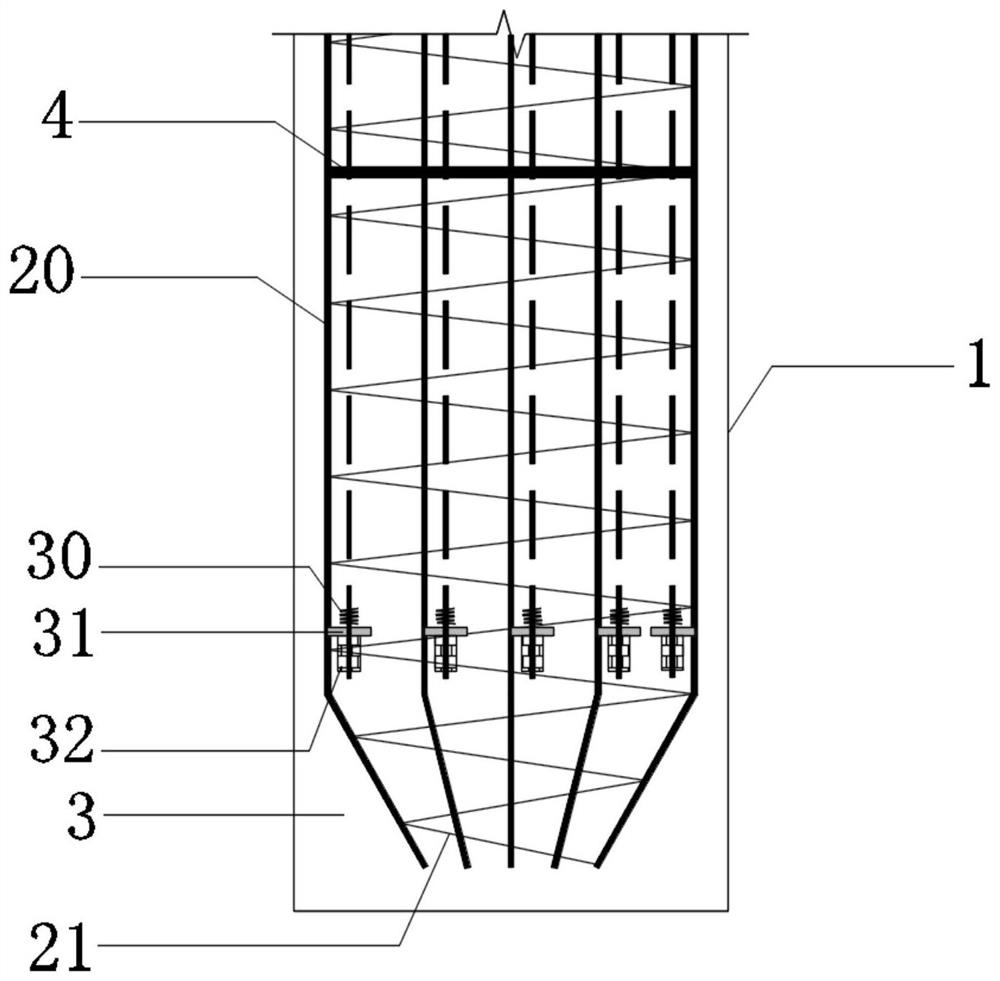

[0040] see Figure 1-6 , a new unbonded post-tensioned prestressed uplift pile structure, comprising a pile hole 1, a steel cage 2 is placed in the pile hole 1, concrete is poured in the pile hole 1, the concrete and the The reinforcement cage 2 forms the uplift pile body 3, the bottom of the uplift pile body 3 is provided with a number of pile bottom anchoring devices, and the top of the uplift pile body 3 is provided with a number of pile top anchors corresponding to the plurality of pile bottom anchorage devices. device, the pile bottom anchoring device is provided with an unbonded steel strand 33, and the top of the unbonded steel strand 33 is connected with the pile top anchoring device.

[0041] A new type of unbonded post-tensioned prestressed uplift pile structure provided by the above embodiment, wherein a reinforcement cage 2 is arranged in the pile hole 1, and concrete and the reinforcement cage 2 are poured in the pile hole 1 to form the uplift pile body 3. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com