Packaging structure and packaging method of high-power radio frequency device

A technology of radio frequency device and packaging structure, which is applied in the manufacturing of semiconductor devices, electric solid state devices, and semiconductor/solid state devices, etc., can solve the problem of inability to achieve high power output, save product development cycle, realize mass production, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

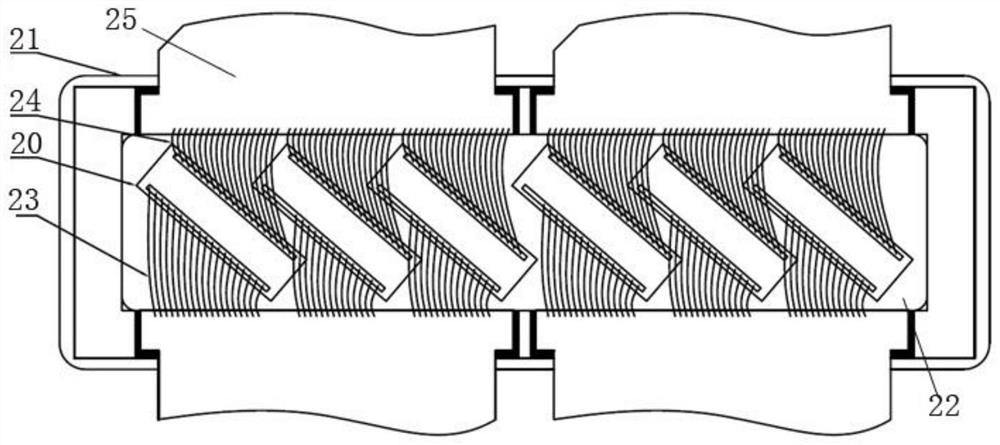

[0030] Such as image 3 , 4 As shown, the packaging structure of the high-power radio frequency device of the present invention includes a plurality of parallel radio frequency power chips 20 and a packaging flange 21, and a plurality of radio frequency power chips 20 are obliquely arranged in the packaging cavity 22 of the packaging flange 21, and many Each RF power chip 20 forms a certain angle with the package cavity 22, and multiple RF power chips 20 are preferably arranged in parallel at the same angle. The subsequent process can be made simpler. The number of RF power chips depends on the selected package size and the selected chip size.

[0031] Such as Figure 5 As shown, when the inclination angle ∠A is determined, the distance between the outermost end of the radio frequency power chip 20 and the package cavity 22 is greater than or equal to a set threshold, such as the minimum distance d. Specifically, the maximum inclination angle cannot make the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com