Wet dust removal equipment for industrial waste gas dust

A technology for wet dust removal and industrial waste gas, which is applied in cleaning methods, use of liquid separation agents, construction, etc., can solve problems such as poor flexibility, inconvenient use, and low efficiency, and achieve good dust removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

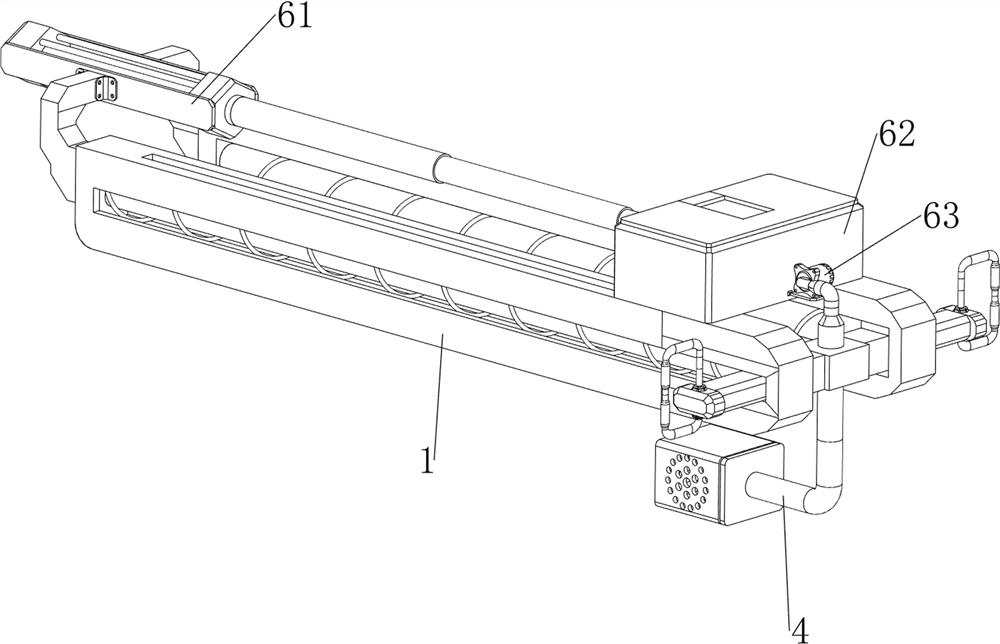

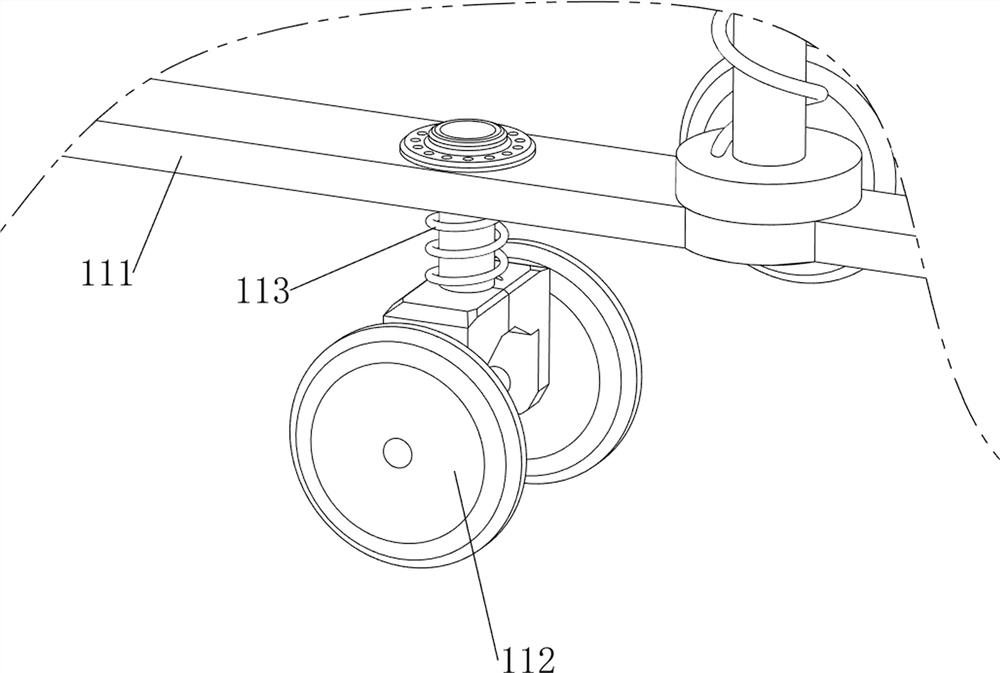

[0035] A wet dust removal equipment for industrial waste gas dust, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 11 and Figure 12 As shown, it includes a slide rail 1, a first slide bar 2, a first spring 3, a spray head 4, a moving handle 5, an automatic spraying mechanism 6, a lifting mechanism 9 and a moving mechanism 11, and the top of the moving mechanism 11 is provided with a lifting mechanism 9, The top of the lifting mechanism 9 is symmetrically provided with slide rails 1 front and back, and the slide rails 1 are provided with a first slide bar 2. There are two first slide bars 2, and a nozzle 4 is slidingly provided between the right sides of the first slide bar 2. The first spring 3 is connected between the front and rear sides of the nozzle 4 and the first slide bar 2. There are two first springs 3 in total. The upper part of the nozzle 4 is symmetrically provided with a moving handle 5, and the top of the slide rail 1 is provided with an automa...

Embodiment 2

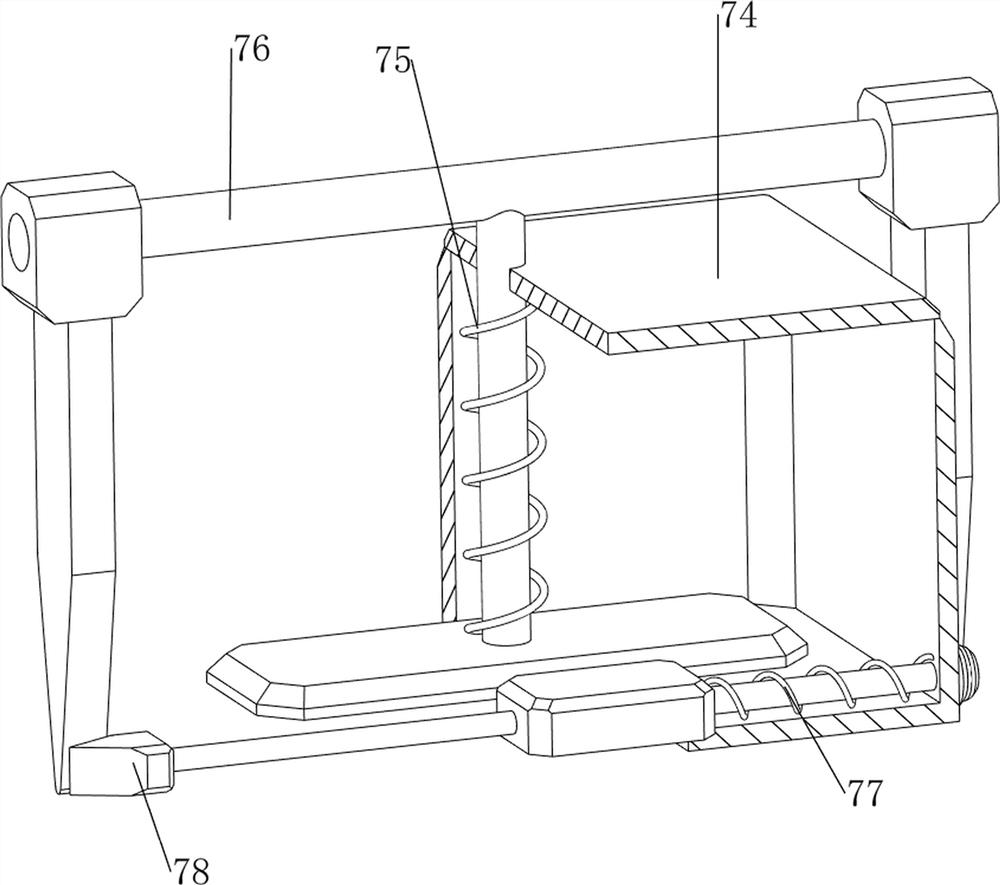

[0044] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 13 , Figure 14 and Figure 15 As shown, a charging mechanism 7 is also included, and the charging mechanism 7 includes a first wedge-shaped rod 71, a second wedge-shaped rod 72, a first fixed rod 73, a casing 74, a second spring 75, a pull rod 76, and a third spring 77 And stop bar 78, the water tank 62 left side is provided with the second wedge-shaped bar 72 symmetrically front and back, the right side of water tank 62 front portion is provided with the first wedge-shaped bar 71, and the outer wall in the middle of slide rail 1 is provided with the first fixed bar 73, the first A housing 74 is provided between the fixed rods 73, a pull bar 76 is provided for sliding on the left side in the housing 74, a second spring 75 is connected between the bottom of the pull rod 76 and the inner top wall of the housing 74, and a stopper is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com