Camellia seed screening device based on pipeline type winnowing structure

A screening device and pipeline technology, applied in solid separation, cleaning methods and utensils, separation of solids from solids by air flow, etc., can solve the problems of a lot of labor, increase labor costs, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

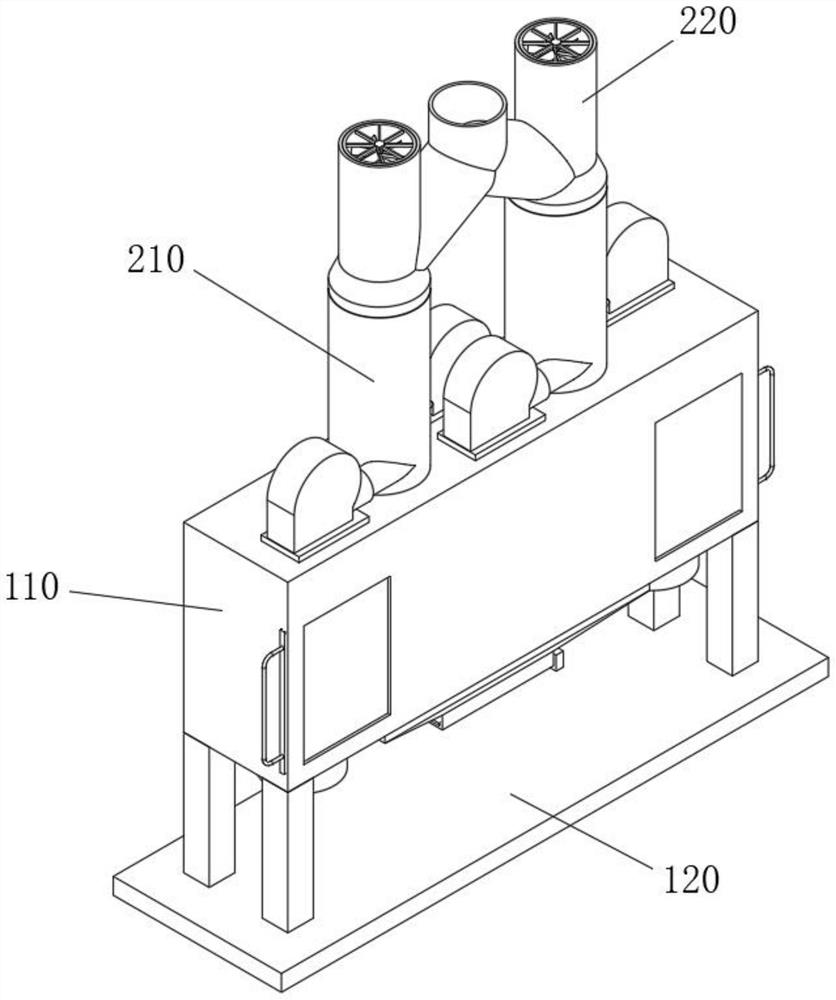

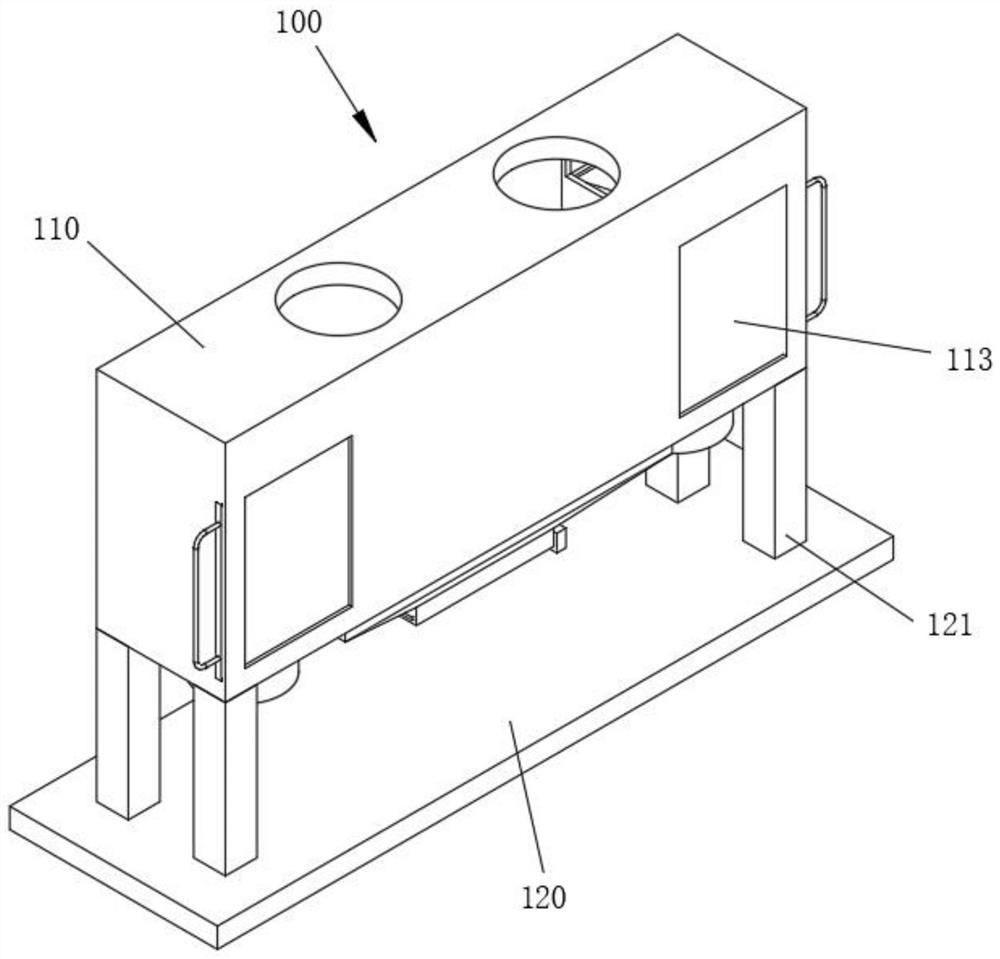

[0051] see Figure 1-Figure 11 As shown, the purpose of this embodiment is to provide a screening device for camellia seed based on a pipeline type winnowing structure, including a cleaning mechanism 100 and a screening mechanism 200 connected above the cleaning mechanism 100;

[0052] The cleaning mechanism 100 includes at least a feeder box 110. Inside the feeder box 110, there is a feeder tank 1100 for collecting the sieved Camellia oleifera seeds. Both sides of the top of the feeder tank 1100 are provided with fixed ports 1101 for connecting with the screening mechanism 200;

[0053]The screening mechanism 200 at least includes a screening pipeline 210. There are two screening pipelines 210. The bottom ends of the two screening pipelines 210 are respectively fixedly connected to the inside of the fixed port 1101. A lumen 2100 is opened inside the screening pipeline 210, and the bottom ends of the lumens 2100 are connected to A screen 211 is arranged to screen the camellia ...

Embodiment 2

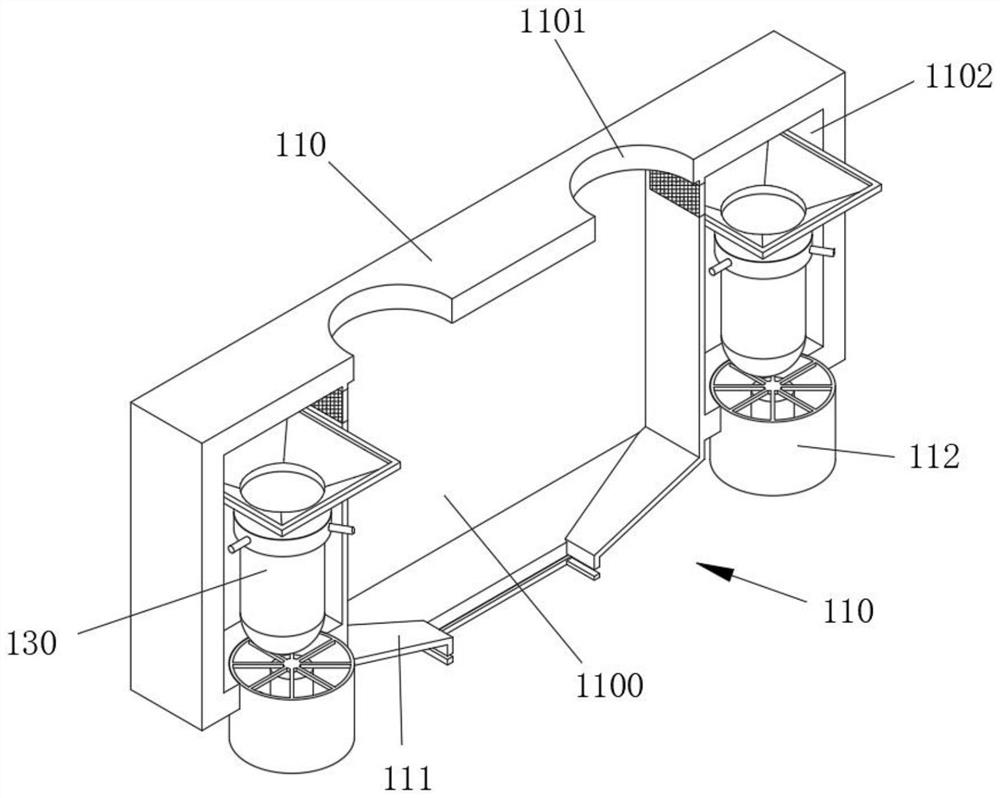

[0068] Considering the need to clean up the dust generated by sieving camellia seeds, please refer to figure 2 , image 3 , Figure 4 and Figure 6 As shown, the purpose of this embodiment is: both sides of the hopper 1100 are provided with a cleaning bin 1102, and a filter screen 1103 is provided between the cleaning bin 1102 and the hopper 1100 to filter out the dust inside the hopper 1100 and clean it up. The bottom end of the warehouse 1102 is provided with an air exhaust port 1104, and an air outlet fan 112 is installed inside the air outlet 1104, and the air outlet fan 112 works to facilitate the extraction of dust inside the material trough 1100.

[0069] In order to further collect the dust, a dust removal device 130 is installed inside the cleaning chamber 1102. The dust removal device 130 includes at least a dust removal bucket 131, a connector 132 is connected below the dust removal bucket 131, and a cloth bag 1321 is fixed at the bottom of the connector 132. , ...

Embodiment 3

[0074] Considering that the camellia seed inside the lumen 2100 needs to be discharged, please refer to Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the purpose of this embodiment is: the bottom end of the air inlet pipe 222 is provided with an intubation tube 2222, and the intubation tube 2222 is plugged and matched with the opening at the top of the lumen 2100, so as to facilitate the separation of the feeding device 220 from the screening pipeline 210, and the screen 211 Slidingly connected to the inside of the lumen 2100, the camellia oleifera seeds can be taken out by sliding the screen 211 upwards.

[0075] In order to fix the screen 211, the center of the upper surface of the screen 211 is provided with a connecting rod 2111, the top of the connecting rod 2111 is provided with a fixed rod 2112, both sides of the top of the screening pipe 210 are provided with a slot 2102, and the two ends of the fixed rod 2112 Engage with the slot 2102 to play the role...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com