Pipe traction device and traction method

A pulling device and pipe technology, applied in the field of pipe pulling devices, can solve the problems of difficult operation, time-consuming and laborious occupation of space, etc., and achieve the effect of reducing length and lengthening length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

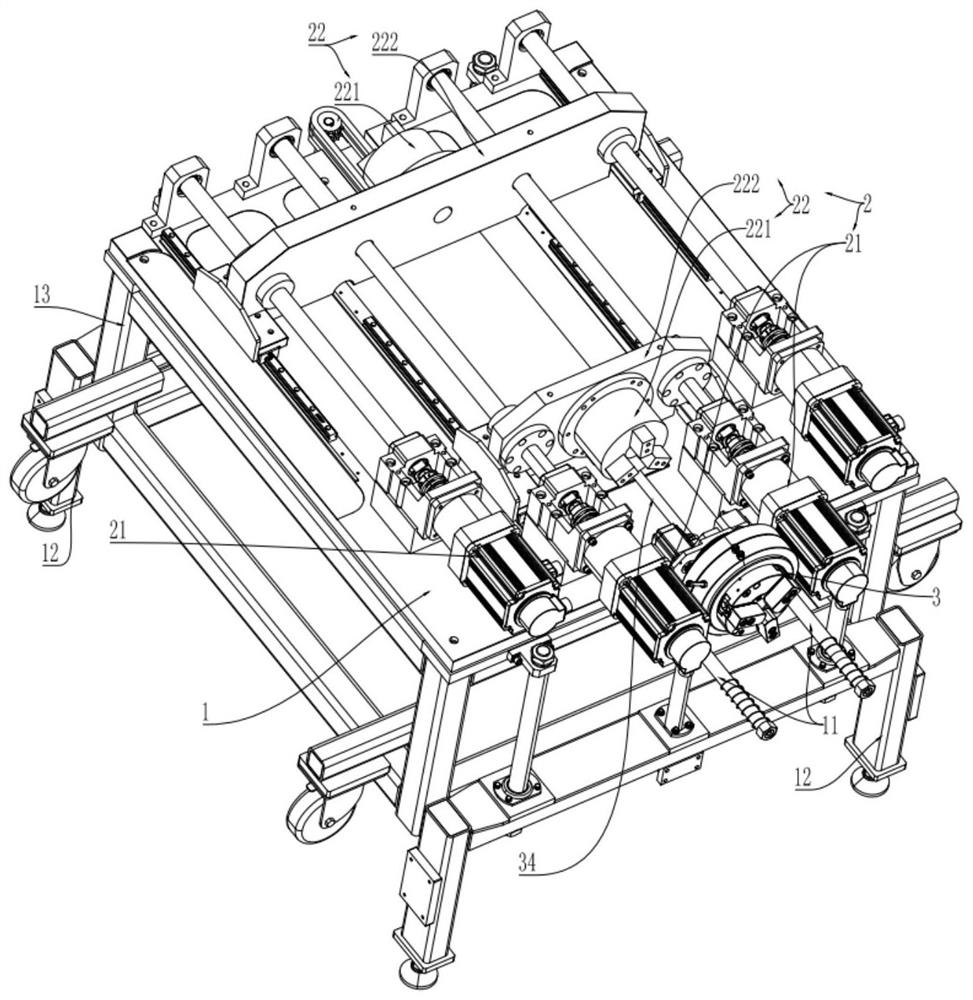

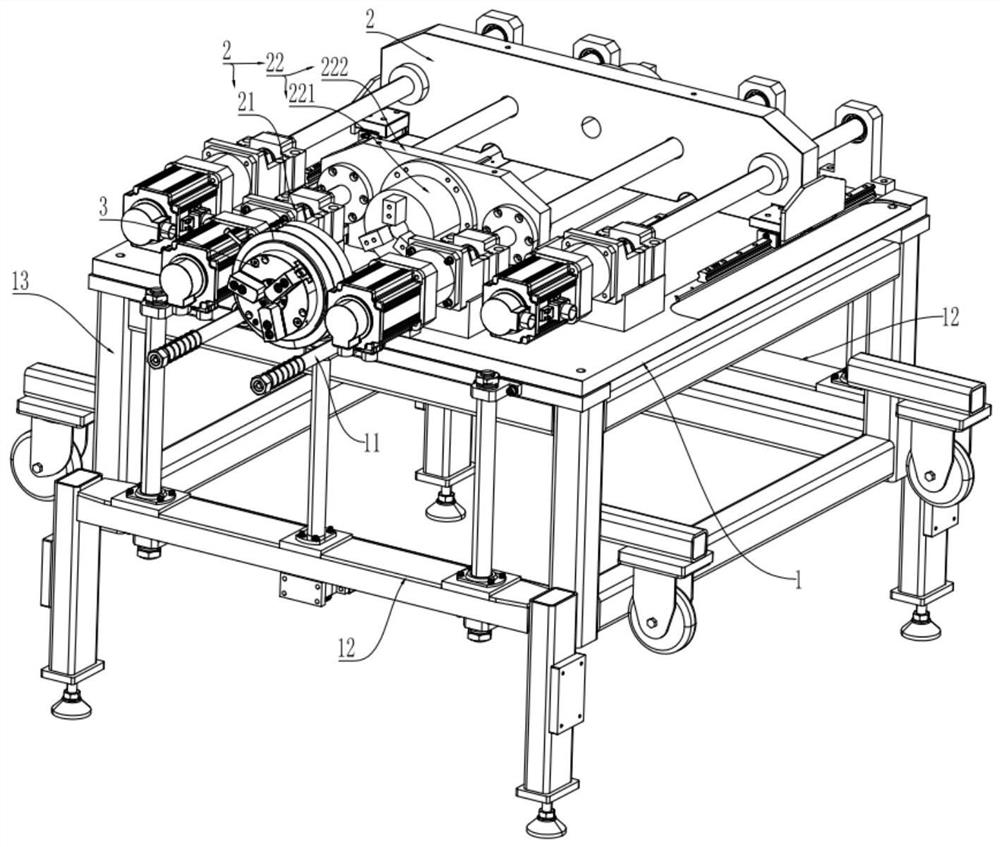

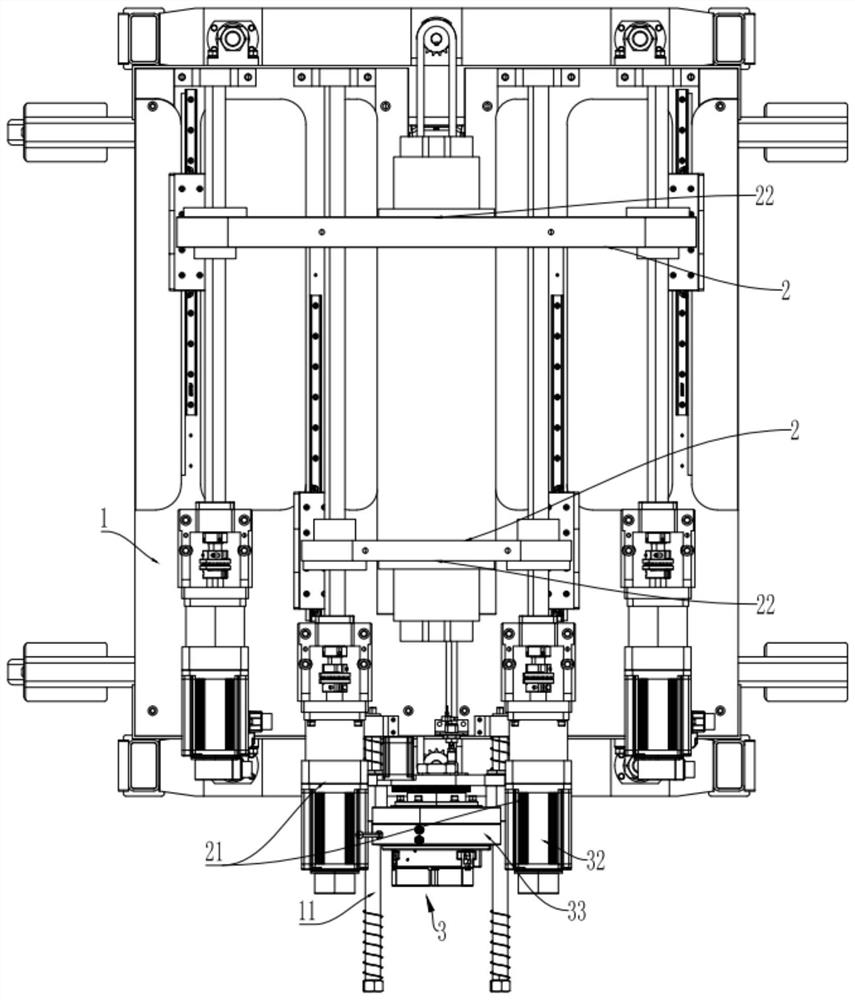

[0037] The embodiment is basically as attached Figure 1 to Figure 9 As shown, a pipe pulling device includes a frame 1 and a pulling mechanism on the frame 1, and an elastic mechanism 3. The pulling mechanism includes at least two pulling assemblies 2, and each pulling assembly 2 includes a driver 21 and is used for Clamp or loosen the clamp 22 of the traction tube, the driver 21 is used to drive the clamp 22 to move axially along the pipe, different drawing components 2 alternately clamp the traction tube to drive the traction tube to move at a constant speed; the clamp 22 includes Chuck 221 and pull plate 222, the chuck 221 is fixedly connected to the pull plate 222, the chuck 221 is used to clamp or loosen the traction pipe, the pull plate 222 is slidably connected to the frame 1 along the pipe axial direction, and the driver 21 drives The drawing plate 222 moves axially; in this embodiment, there are two drawing assemblies 2 , the driver 21 adopts a ball screw structure, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com