Joist barrow for railway bridge deck system in steel truss girder and using method of joist barrow

The technology of steel truss girder and bridge deck system is applied in the field of truss trolley for railway bridge deck system in steel truss girder, which can solve the problems of inability to meet the requirements of transportation and hoisting, limited operation space of steel truss girder, lack of flexibility, etc. Achieve the effect of saving track laying costs, improving economic rationality and construction efficiency, and convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

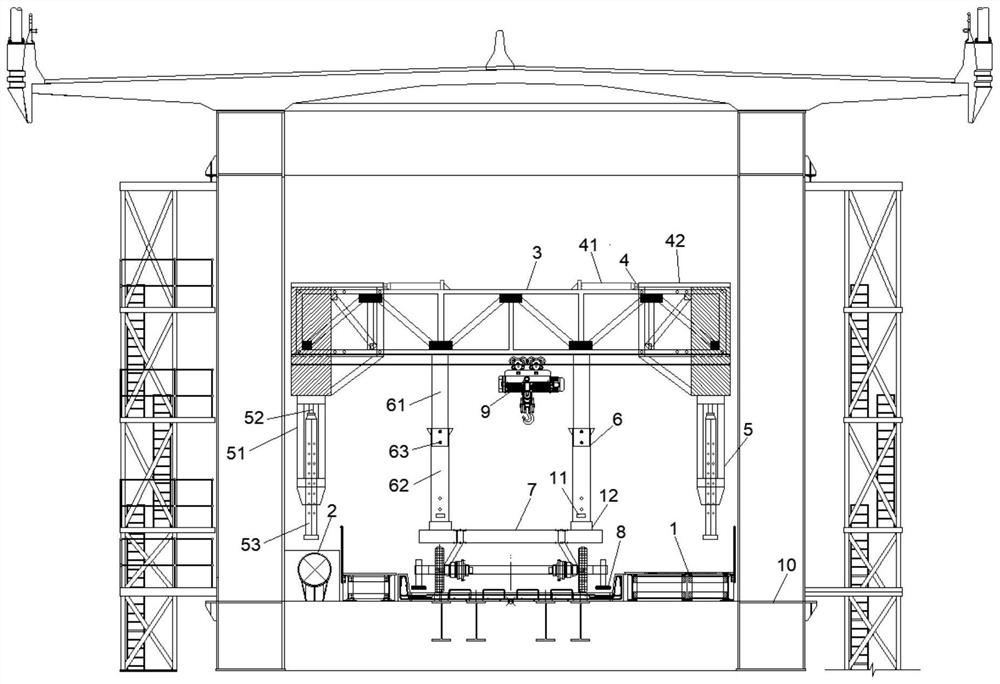

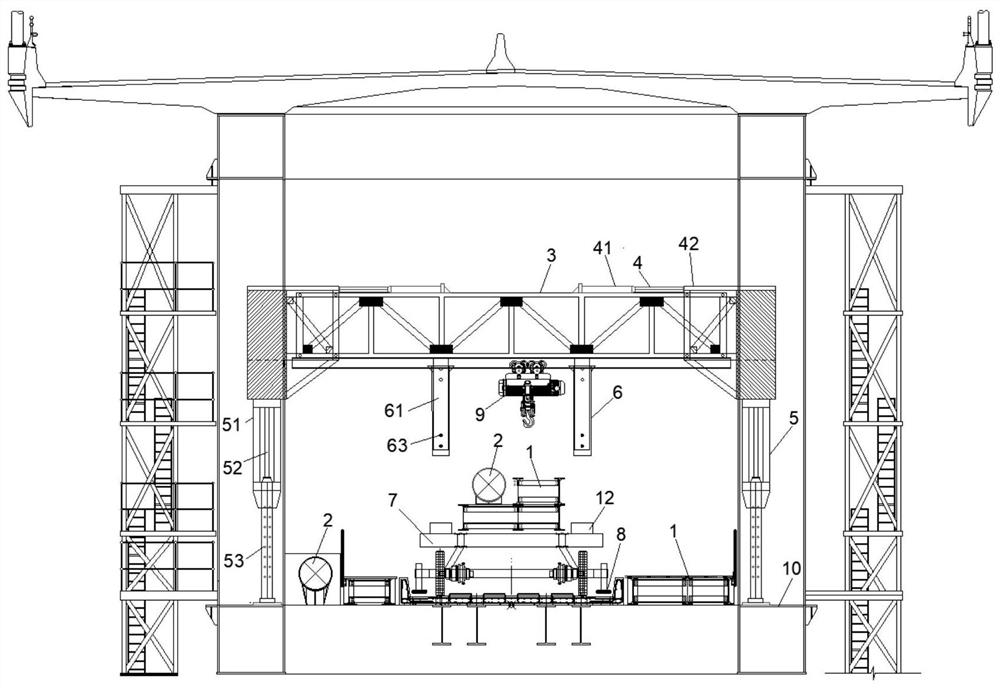

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

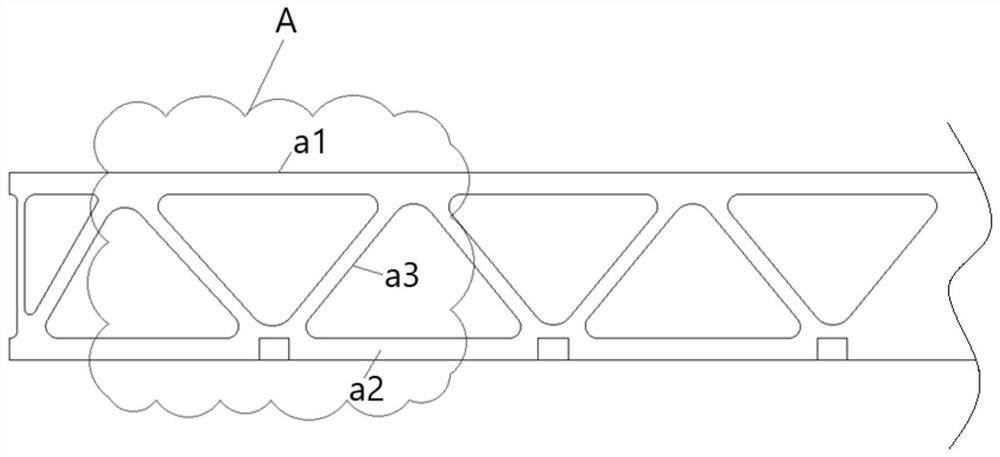

[0057] see Figure 2 to Figure 7 As shown, the application provides a steel truss girder inner railway bridge deck system truss car, including:

[0058] The transfer vehicle 7 is provided with a bearing platform 71 on it. Specifically, the transfer vehicle 7 can be a wheel-loaded pallet truck, and a load-bearing platform 71 is set on its top. The load-bearing platform 71 can carry workpieces that need to be lifted, such as UB steel 1 and natural gas pipeline 2, and can also be used in the second vertical direction. When the telescopic device extends and lowers its end, it supports the end of the second vertical telescopic device 6 . Transfer car 7 can directly advance on the concrete surface 13 that is provided with pre-embedded T16 steel bar 14 of road bridge deck system, and the way of advancing is more flexible.

[0059] The combined steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com