Non-contact mud layer interface instrument convenient to move

A non-contact, easy-to-move technology, used in engine lubrication, instruments, engine components, etc., can solve problems affecting detection accuracy, detection head shaking, pollution of connecting wires, etc., to achieve a wide range of applications, avoid confusion, and ensure normal operation. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

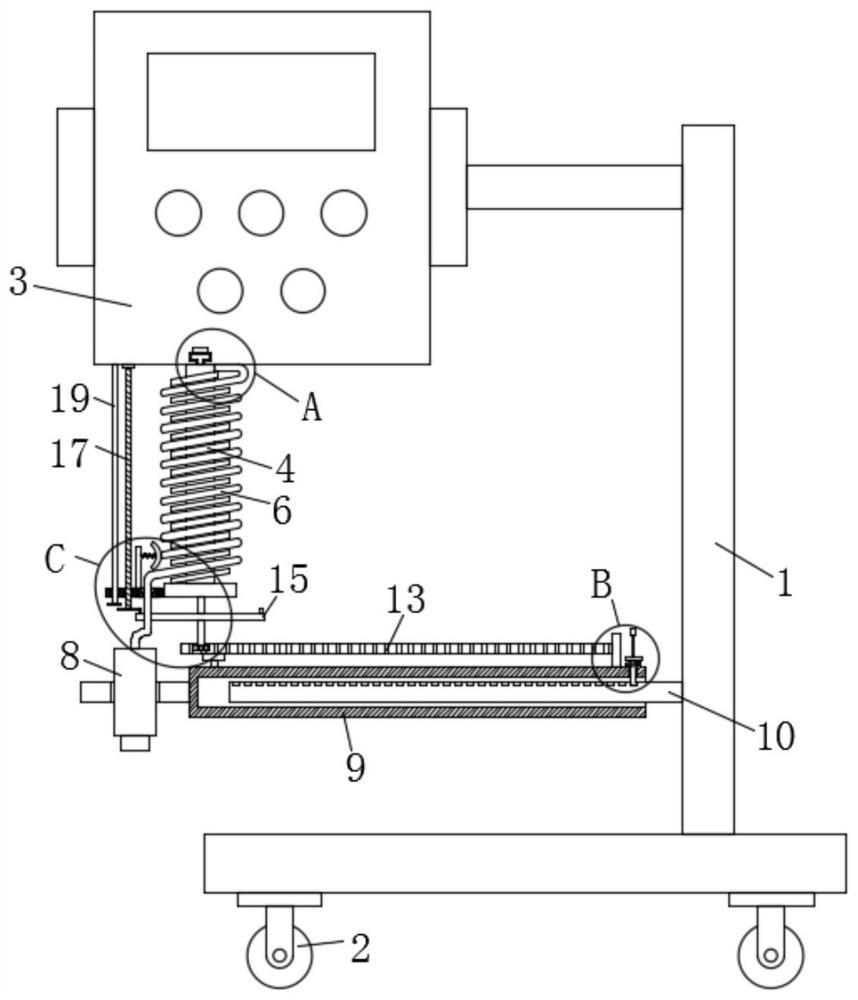

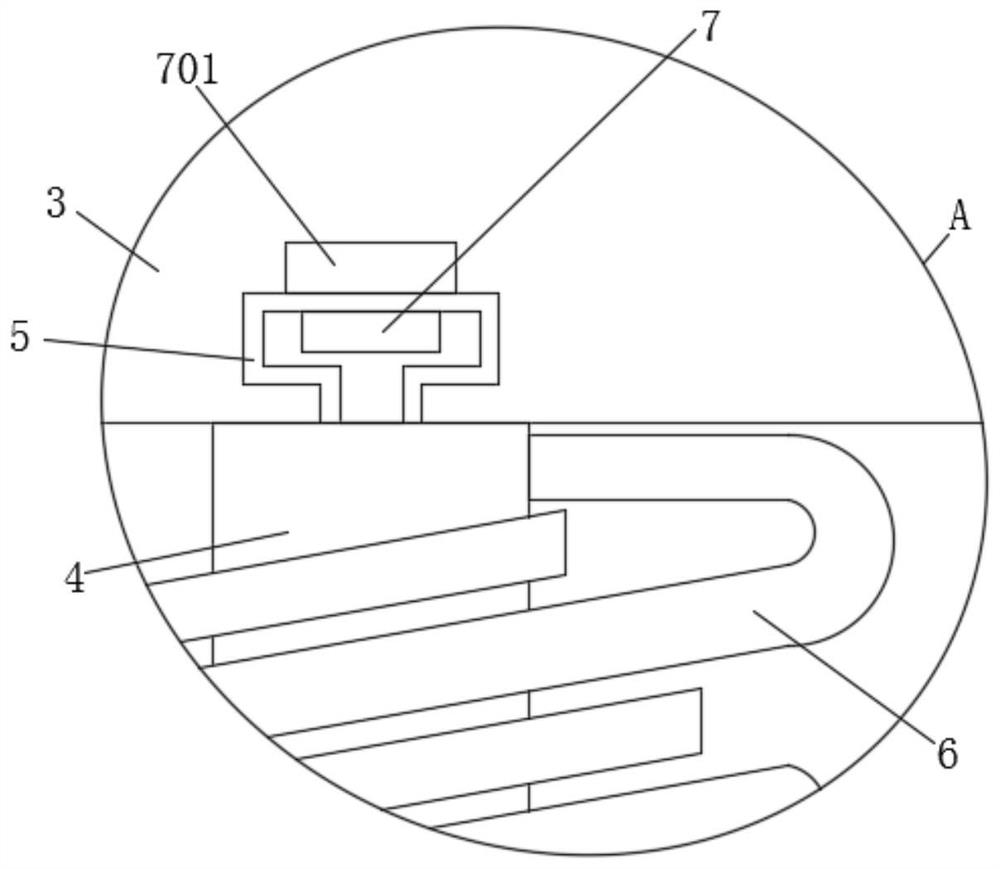

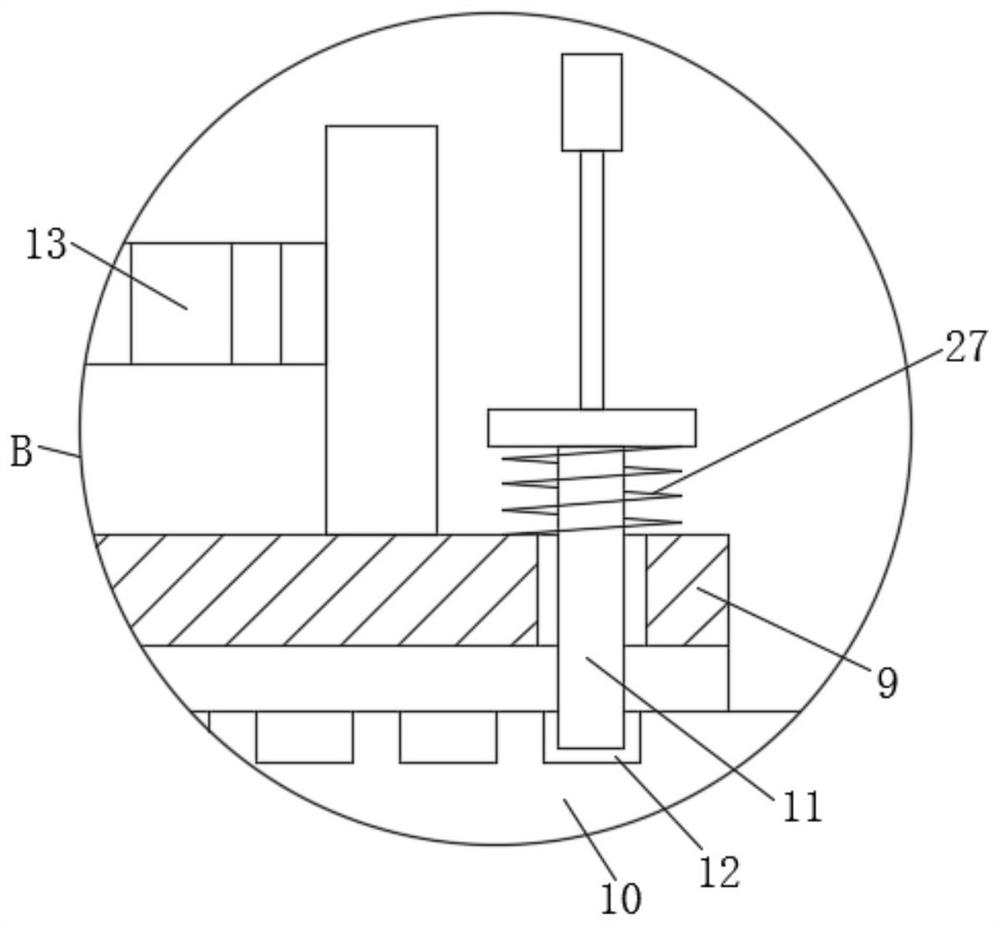

[0031] refer to Figure 1-6 , a non-contact mud layer interface instrument that is convenient to move, including a bracket 1, universal wheels 2 are fixedly installed at the four corners of the lower end of the bracket 1, an interface instrument body 3 is fixedly installed at the left end of the bracket 1, and the interface instrument body The lower end of the 3 is provided with a screw rod 4, and the screw rod 4 is wound with a wire 6, and the lower end of the interface instrument body 3 is provided with a turning groove 5 corresponding to the screw rod 4, and the screw rod 4 is rotationally connected with the interface instrument body 3. Conductive block two 701 is fixedly installed in the lower end of body 3, and conductive block one 7 is fixedly installed on the upper end of screw rod 4 corresponding to conductive block two 701. 7 is fixedly connected, the lower end of the wire 6 is fixedly installed with a detection head 8, the right end of the detection head 8 is fixedly...

Embodiment 2

[0034] refer to Figure 1-6, in this embodiment, it is basically the same as Embodiment 1, and more optimally, a rack 13 is fixedly installed on the upper end of the sleeve 9, a transmission gear 14 is engaged on the left side of the front end of the rack 13, and a transmission gear 14 is fixedly installed on the upper end of the transmission gear 14. Rotating disk 15, the upper end of rotating disk 15 is fixedly installed on the screw rod 4, the lower left side of the screw rod 4 is provided with a whole line board 16, and the wire 6 runs through the right side of the whole line board 16, and the said whole line board 16 is screwed There is a screw 17, the upper end of the screw 17 is rotatably connected with the interface instrument body 3, the lower end of the screw 17 is fixedly equipped with a fixed gear 18, the upper end of the turntable 15 is fixedly equipped with a ring gear 181, and the fixed gear 18 and the ring gear 181 mesh with each other, the screw 17 is rotation...

Embodiment 3

[0037] refer to Figure 1-6 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, the upper side of the whole line board 16 is provided with a loosening plate 24, and the right end of the loosening plate 24 is attached to the wire 6, and the loosening plate 24 is attached to the wire 6. The left end of the plate 24 is fixedly equipped with a spring three 25, and the left end of the spring three 25 is fixedly installed with a riser 26, and the lower end of the riser 26 is fixedly connected to the whole line plate 16;

[0038] During use, under the action of the spring three 25, the anti-loosening plate 24 provided has the effect of squeezing and preventing the loosening of the wire 6 on the upper side of the screw rod 4 when the wire 6 is unwound, thereby preventing the wire 6 from being loosened. In the process of unwinding, there is falling off.

[0039] working principle:

[0040] When the present invention is in use, the positioning rod 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com