Propeller hub cap fin optimization design method based on entropy production analysis

An optimized design and propeller hub technology, applied in the field of propeller hub cap fins, can solve problems such as optimization and improvement of hub cap fins, time-consuming and labor-intensive pool tests, etc., to achieve the effect of reducing entropy loss and good hydrodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

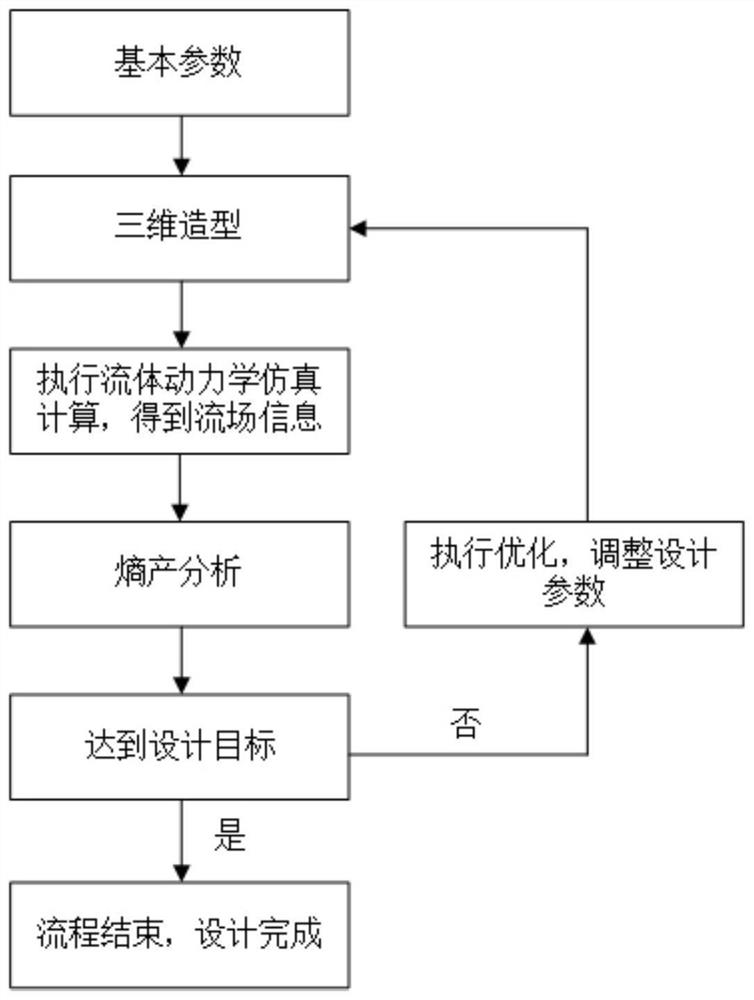

[0033] Such as figure 1 As shown, the method for optimizing the design of propeller hub cap fins based on entropy production analysis, its specific steps include:

[0034] Step 1. Determination of basic parameters: determine the working conditions for which the propeller needs to be optimally designed. The determined basic parameters are mainly the advance speed coefficient J of the propeller and the diameter D of the propeller; taking a certain type of four-blade propeller as an example, the diameter D of the propeller=250mm, Advance speed J=0.5, speed n=1200rpm;

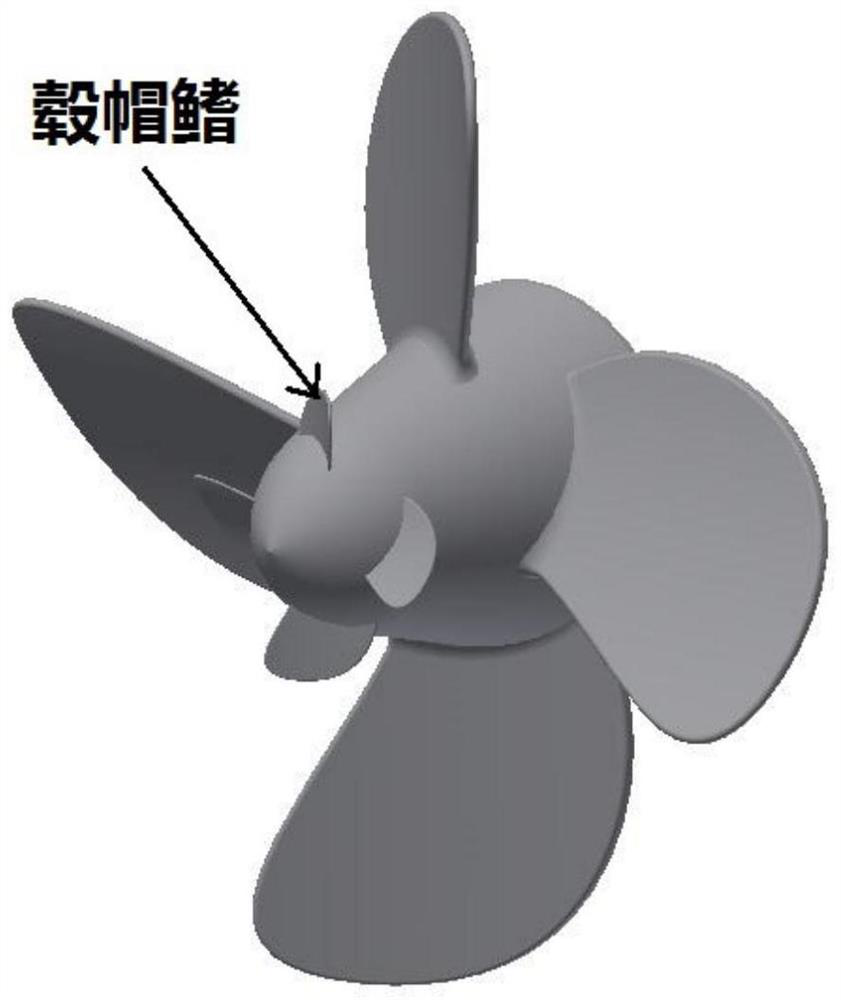

[0035] The hub cap fin is designed with this propeller, and the constraint range is given for the hub cap fin blade diameter d and the hub cap fin blade installation angle α, and the constraint range is:

[0036] 0.2D≤d≤0.4D;

[0037] 20°≤α≤60°; the number of blades of the hubcap fin is consistent with the number of propeller blades;

[0038] Step 2, three-dimensional modeling: Carry out three-dimensional modeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com