Bendable high-strength cable bridge

A cable tray, high-strength technology, applied to electrical components and other directions, can solve the problems of increasing the difficulty of the bridge splicing work, the unadjustable rotation angle, the offset and shaking of the bridge, etc. Offset shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

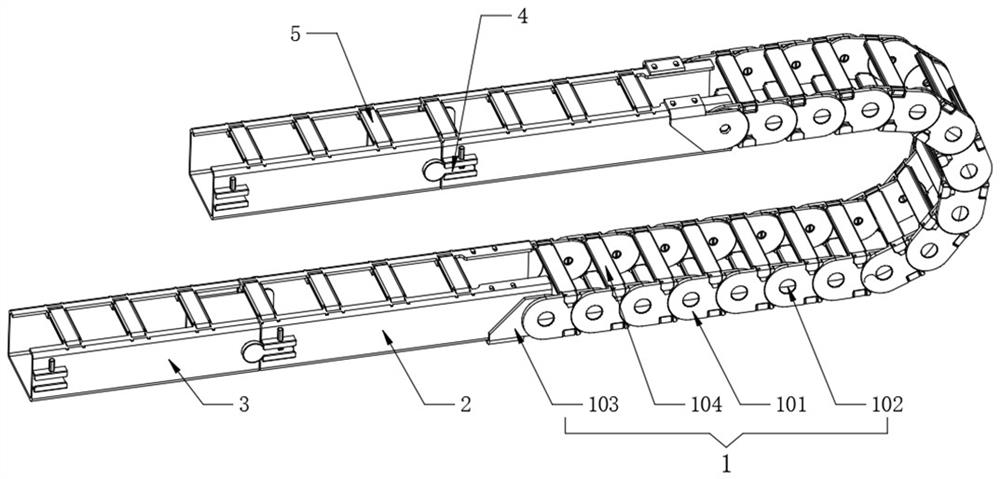

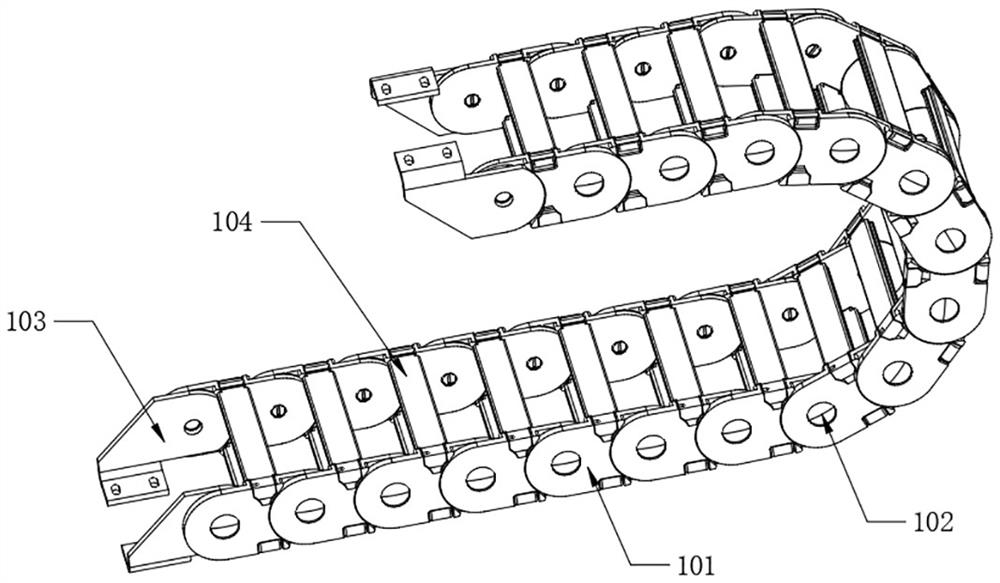

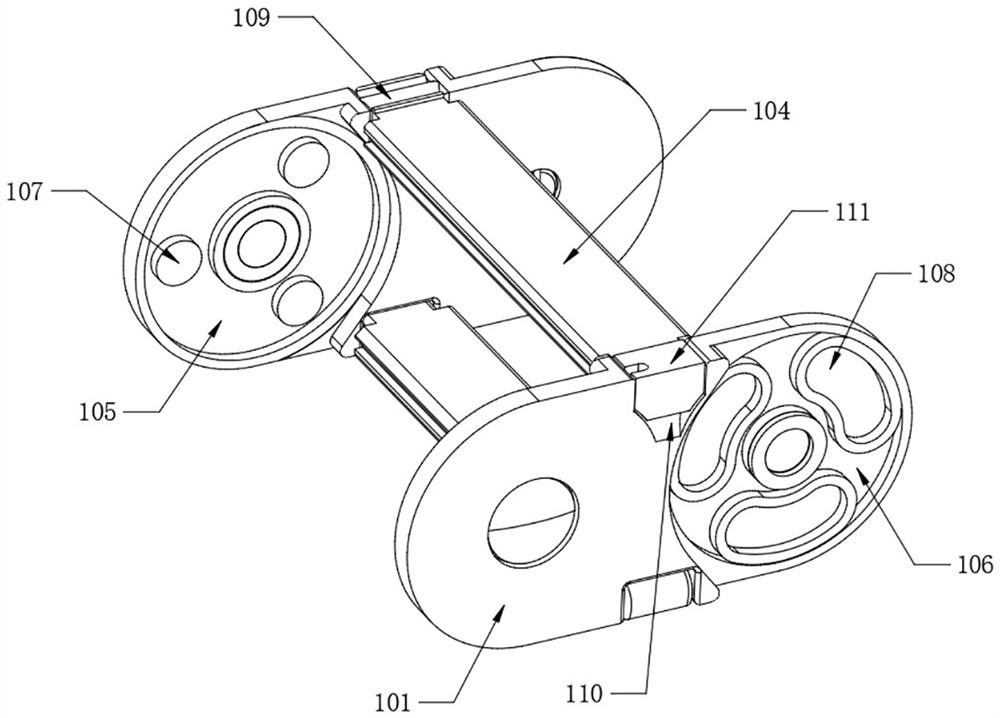

[0038] Refer to attached figure 2 and image 3 , the interior of the transfer bridge assembly 1 is spliced with single-section adapters 101 one by one, and the adjacent single-section adapters 101 are rotated and connected one by one. 104, the two adjacent single-section adapters 101 are rotationally connected by the provided connecting pin 102, the inner walls on both sides of one end of the single-section adapter 101 are fixed with an inner groove 105, and the other side of the single-section adapter 101 Two inner grooves 106 are fixedly formed on the outer walls of both sides of one end, and relative rotation will occur between multiple single-section adapters 101 , and the center of rotation is the corresponding connecting pin 102 .

[0039] Refer to attached image 3, the inner wall of inner groove 1 105 is equidistantly fixed with inner bottom pins 107, the inner wall of inner groove 2 106 is equidistantly fixed with inner arc grooves 108, and the number of inner bo...

Embodiment 2

[0044] Refer to attached Figure 5 One end of the terminating bridge 2 is provided with a screw hole 2 21 corresponding to the screw hole 112, and one end of the splicing bridge 3 is fixedly provided with an interpolation frame 31, and the interpolation frame 31 is movably inserted into one end of the terminating bridge 2, and in the terminating bridge 2 and the splicing bridge 3 are spliced, the interposer frame 31 will be inserted into one end of the terminating bridge 2 to assist the connection between the two.

[0045] Refer to attached Figure 5 The splicing assembly 4 also includes an outer inserting rod 401 and an outer rail frame 403, the outer inserting rod 401 is fixedly arranged on the outer walls of one end of the splicing bridge 3 close to the inner frame 31, and the outer rail frame 403 is fixedly arranged on the other end of the splicing bridge 3 The outer walls on both sides, the outer walls on both sides of the end bridge 2 away from the screw hole two 21 are...

Embodiment 3

[0049] Refer to attached Figure 7 , both sides of the terminating bridge frame 2 and the splicing bridge frame 3 are equidistantly fixed with side center rods, the top protector 5 also includes a top guard plate 501, one end of the top guard plate 501 is fixedly provided with a sleeve 502, and the sleeve 502 is movably sleeved on On the surface of the side center rod, the other end of the top guard plate 501 is fixedly provided with a card tube 503, and the card tube 503 is movably engaged with the side center bar on the other side. The structure is the same. After the splicing of each bridge frame is completed, the top guard plate 501 is covered, and the card tube 503 at the other end of the top guard plate 501 is clamped on the side center rod on the other side, so that the surface of the cable is protected and can block certain The fall of foreign objects.

[0050] Refer to attached Figure 8 , the inner end of the top guard plate 501 is rotatably installed with an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com