Drum-type washing machine

A drum type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing devices, etc., capable of solving problems such as washing, dehydrating or drying of unwashable items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

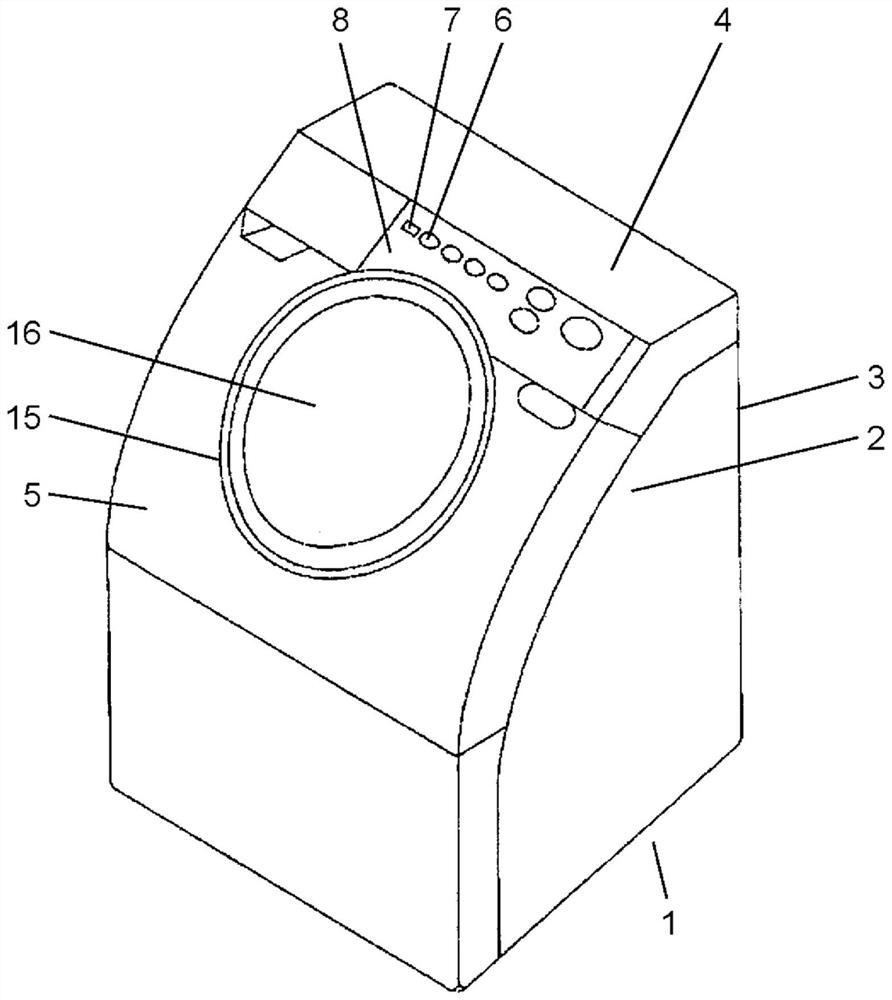

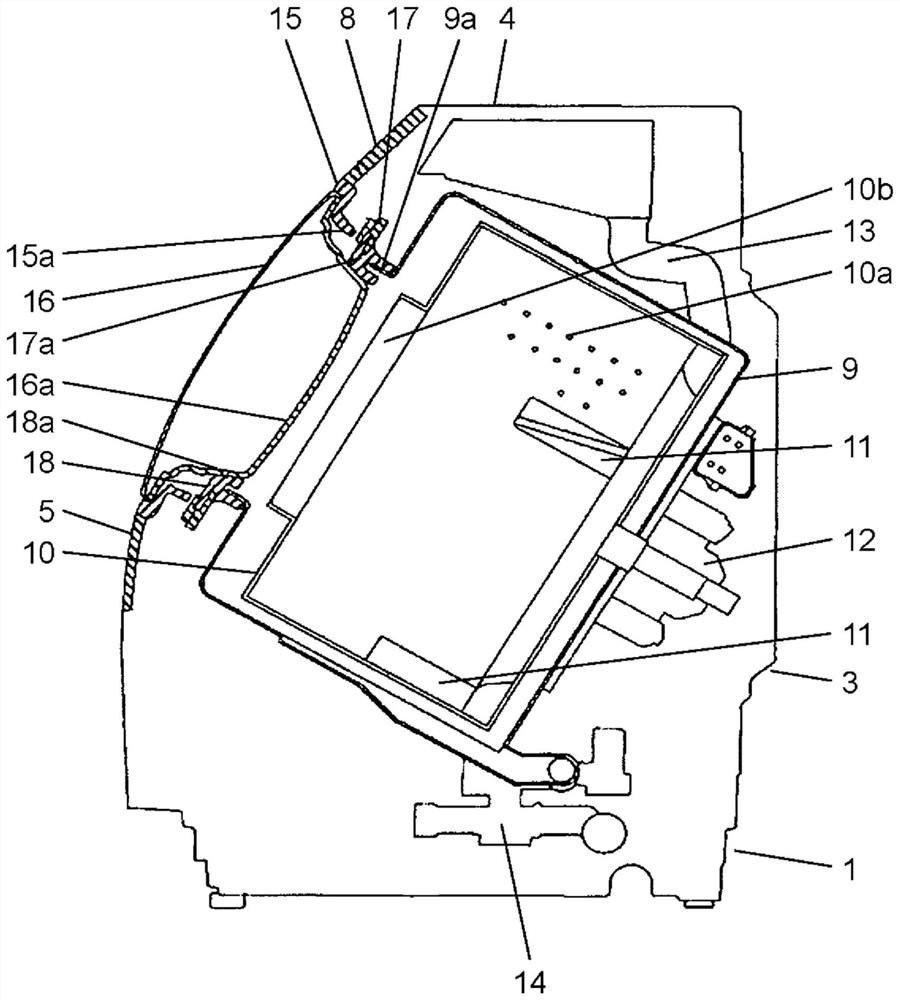

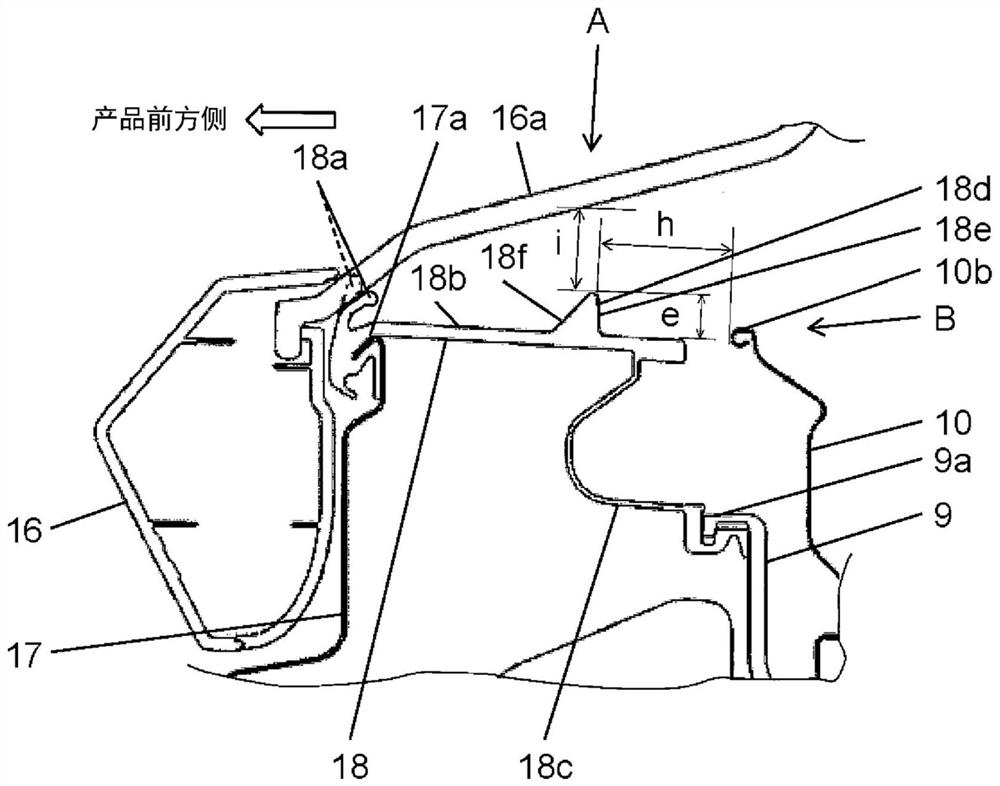

[0026] figure 1 It is an external perspective view of the front-loading-type washing machine of embodiment. figure 2 It is a longitudinal sectional view of the front-loading-type washing machine of embodiment.

[0027] exist figure 1 , figure 2 Among them, the front surface of the main body 1 is made into a smooth upper receding curved surface, and the main body 1 has divided left and right side panels 2 made of metal plates, a detachable back panel 3, and a plurality of metal plate made of connecting left and right side panels 2. The connecting plate (part of which will be described later), the top plate 4 formed of synthetic resin, and the front panel member 5 and the like. An operation panel 8 is provided above the front panel member 5. On the operation panel 8, a switch operation section 6 for performing various settings and a display section 7 for displaying the contents of the settings and the like are arranged.

[0028] The water tank 9 is elastically supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com