Preparation method of water-based UV curing resin

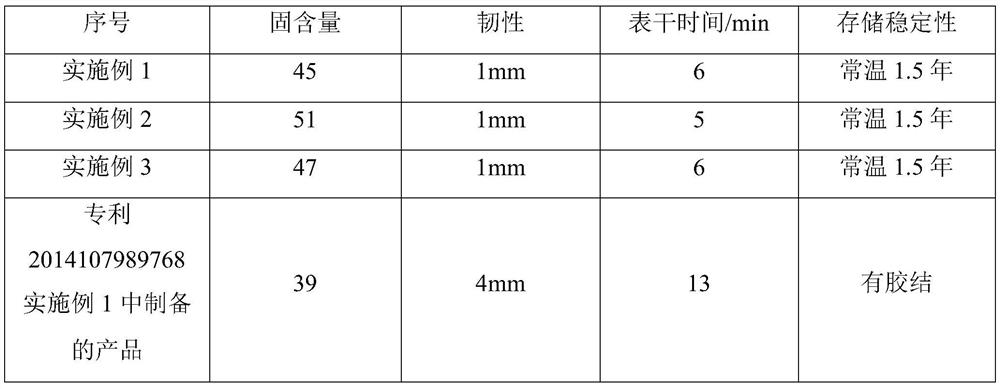

A curing resin, water-based technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problem of little application research, and achieve the effects of good stability, fast curing speed and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the water-based UV curable resin described in the present embodiment 1 is made up of the following steps:

[0044] (1) Introducing hydroxyl groups into ricinoleic acid to produce castor oil-based polyols

[0045] Add 300 g of ricinoleic acid and 105 g of 1,3,5-pentanetriol into a 3000 mL reaction device equipped with a constant pressure dropping funnel, reflux condenser, thermometer and electric stirrer, raise the temperature to 50°C, and react for 1.5 hours. After the esterification reaction is completed, castor oil-based polyols are obtained.

[0046] (2) Introducing hydrophilic groups into castor oil-based polyols

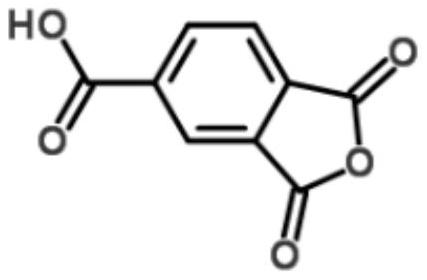

[0047] Add 180 g of trimellitic anhydride into the castor oil-based polyol reaction device, keep the temperature at 65° C. for 2 hours, and then lower the temperature to 40° C.

[0048] (3) Preparation of oligomers

[0049]The product prepared in step (2) was heated up to 100°C, dehydrated under reduced pressure for 0.5 hours,...

Embodiment 2

[0053] The preparation method of the water-based UV curable resin described in the present embodiment 2 is made up of the following steps:

[0054] (1) Introducing hydroxyl groups into ricinoleic acid to produce castor oil-based polyols

[0055] Add 300 g of ricinoleic acid and 120 g of 1,3,5-pentanetriol into a 3000 mL reaction device equipped with a constant pressure dropping funnel, reflux condenser, thermometer and electric stirrer, raise the temperature to 55°C, and react for 1.8 hours. After the esterification reaction is completed, castor oil-based polyols are obtained.

[0056] (2) Introducing hydrophilic groups into castor oil-based polyols

[0057] Add 200 g of trimellitic anhydride into the castor oil-based polyol reaction device, keep it at 70° C. for 2.5 hours, and then lower the temperature to 43° C.

[0058] (3) Preparation of oligomers

[0059] Warm up the product prepared in step (2) to 105°C, dehydrate under reduced pressure for 0.5 hours, then cool down t...

Embodiment 3

[0063] The preparation method of the water-based UV curable resin described in the present embodiment 3 is made up of the following steps:

[0064] (1) Introducing hydroxyl groups into ricinoleic acid to produce castor oil-based polyols

[0065] Add 300 g of ricinoleic acid and 135 g of 1,3,5-pentanetriol into a 3000 mL reaction device equipped with a constant pressure dropping funnel, reflux condenser, thermometer and electric stirrer, raise the temperature to 60°C, and react for 2 hours. After the esterification reaction is completed, castor oil-based polyols are obtained.

[0066] (2) Introducing hydrophilic groups into castor oil-based polyols

[0067] Add 210 g of trimellitic anhydride to the castor oil-based polyol reaction device, keep the temperature at 75° C. for 3 hours, and then lower the temperature to 45° C.

[0068] (3) Preparation of oligomers

[0069] The product prepared in step (2) was heated up to 105°C, dehydrated under reduced pressure for 0.5 hours, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap