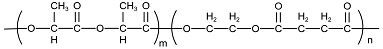

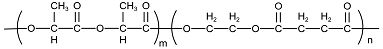

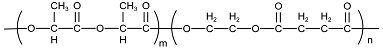

Polylactic acid-polyethylene succinate copolymer and preparation method thereof

A technology of polyethylene succinate and copolymer, applied in the field of polylactic acid-polyethylene succinate copolymer and its preparation, can solve problems such as unsatisfactory synergistic effect, and achieve good physical The effect of mechanical properties, improving brittleness, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a polylactic acid (PLA)-polyethylene succinate (PES) copolymer, the polylactic acid-polyethylene succinate copolymer is composed of L-lactide and poly The ethylene glycol succinate prepolymer is synthesized and prepared under the action of a catalyst, and the specific steps are as follows:

[0024] (1) Synthesis of prepolymer polyethylene succinate:

[0025] Add ethylene glycol and succinic acid into the reaction kettle at a molar ratio of 1.08-1.55:1, add a catalyst, the content is 0.8-2% of the total mass of succinic acid and ethylene glycol, under an inert atmosphere, At 110-195°C, keep the system pressure at 0.20-0.30MPa, and react for 4-8 hours until no small molecular fractions are evaporated. Then, vacuum the obtained esterification reaction product to control the vacuum degree at 200Pa Within 170-200°C under vacuum conditions for 2-8 hours, vacuum extrusion to obtain polyethylene succinate prepolymer;

[0026] (2) Synthesis of polylac...

Embodiment 1

[0035] Add ethylene glycol and succinic acid into the reactor at a molar ratio of 1.45:1, add tetrabutyl titanate catalyst (the content is 0.82% of the total mass of succinic acid and ethylene glycol), and in an inert atmosphere At 175°C, keep the system pressure at 0.25MPa, and react for 6 hours until no small molecular fractions are evaporated, and then vacuumize the obtained esterification reaction product to control the vacuum degree within 200Pa. React at 185°C for 7 hours, and vacuum extrude to obtain a polyethylene succinate prepolymer. Add L-lactide and polyethylene succinate prepolymer in the mass ratio of 2:1 in the reactor, and then add tin dioctoate catalyst (with a content of 1% mole of L-lactide ), under an inert atmosphere, the temperature was raised to 175°C, and the reaction was carried out for 12 hours to obtain a polylactic acid-polyethylene succinate copolymer. The obtained polylactic acid-polyethylene succinate copolymer was dissolved in chloroform, preci...

Embodiment 2

[0037] Add ethylene glycol and succinic acid into the reactor at a molar ratio of 1.45:1, add tetrabutyl titanate catalyst (the content is 0.82% of the total mass of succinic acid and ethylene glycol), and in an inert atmosphere At 175°C, keep the system pressure at 0.25MPa, and react for 6 hours until no small molecular fractions are evaporated, and then vacuumize the obtained esterification reaction product to control the vacuum degree within 200Pa. React at 185°C for 7 hours, and vacuum extrude to obtain a polyethylene succinate prepolymer. Add L-lactide and polyethylene succinate prepolymer in the mass ratio of 2.5:1 in the reactor, and then add tin dioctoate catalyst (with a content of 1% mole of L-lactide ), under an inert atmosphere, the temperature was raised to 175°C, and the reaction was carried out for 12 hours to obtain a polylactic acid-polyethylene succinate copolymer. The obtained polylactic acid-polyethylene succinate copolymer was dissolved in chloroform, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com