Component aerodynamic load correction method based on wind tunnel test

An aerodynamic load and wind tunnel test technology, applied in the field of aerodynamics, can solve the problems of complex test, poor calculation result accuracy, high cost, and achieve the effect of reasonable calculation result and shortened design period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

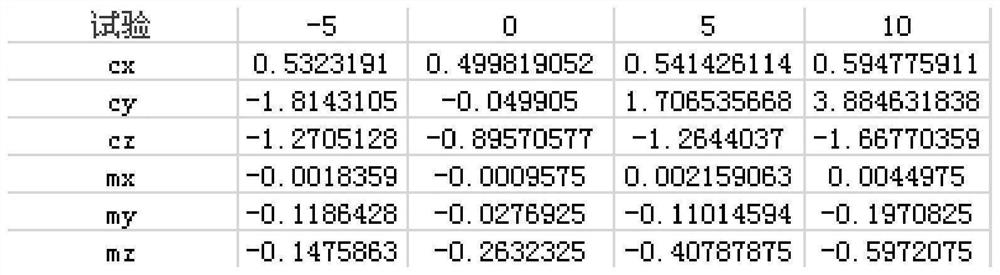

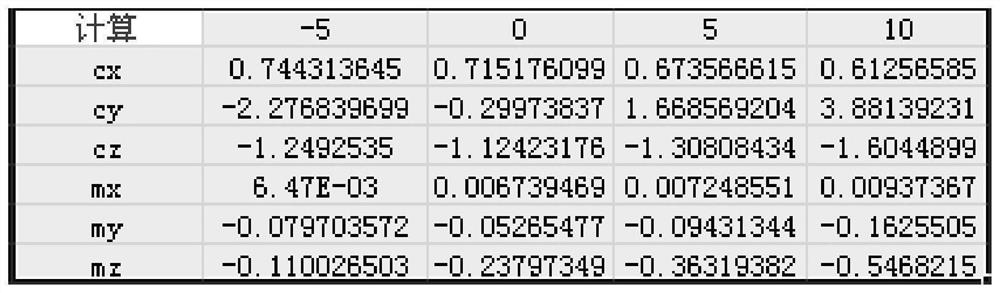

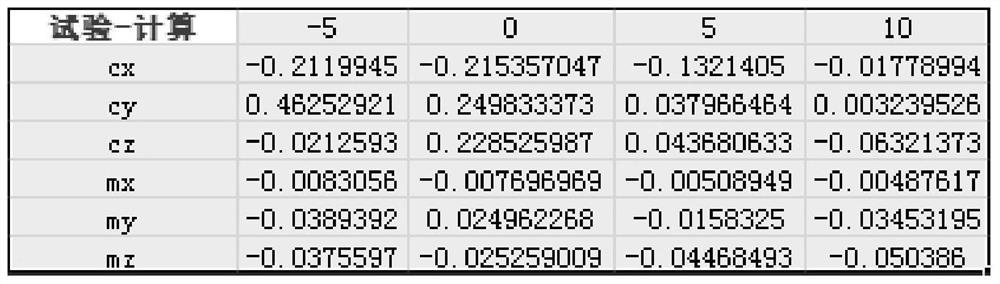

[0031] 1) Write the dynamometric wind tunnel test task book, formulate the content of the wind tunnel test, conduct the dynamometric wind tunnel test, sort out the dynamometric wind tunnel test results, and obtain the total aerodynamic load of the aircraft, see the attached figure 1 ;

[0032] 2) Divide each part of the projectile body and mark it with i, i=1, 2, ... n;

[0033] 3) Calculate the aerodynamic load A' of each component for the fluid 1 , A' 2 ,...,A' n , it is necessary to divide the parts of the missile body. The division method should follow that the parts with large changes in aerodynamic load should be densely divided, and the parts with small changes in aerodynamic load should be divided sparsely. The division method of the parts of the projectile body is as follows:

[0034] For example, the bullet is divided into one section; the section from the bullethead to the front edge of the wing, the section from the front edge of the wing to the rear edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com