Method for estimating and calculating abrasion loss of cutter of shield tunneling machine

A calculation method and technology of wear amount, which is applied in complex mathematical operations, special data processing applications, geometric CAD, etc., and can solve the problem of quantitative prediction of cutter wear amount and service life, single parameter type, limited analysis of theoretical analysis, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The steps and processes of the present invention will be further described below through specific examples. It should be noted that this example is illustrative rather than limiting, and does not limit the protection scope of the present invention.

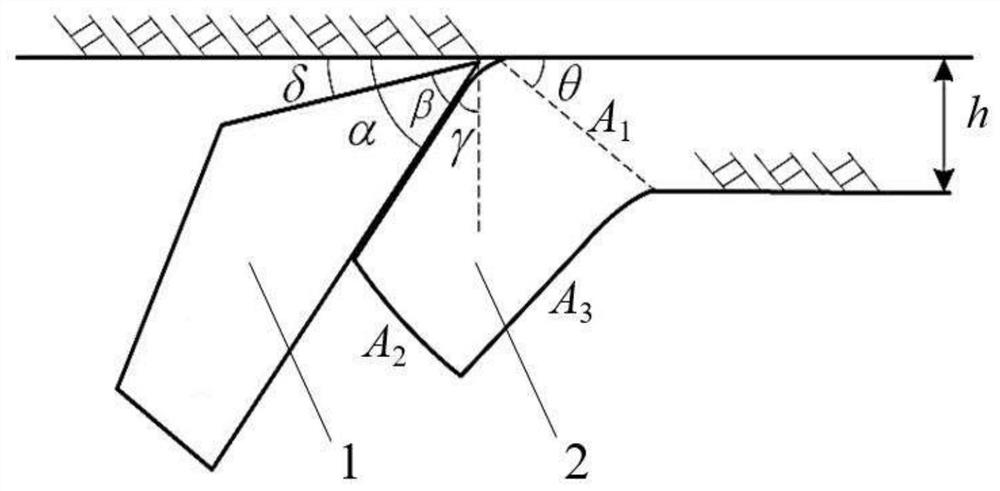

[0031] This embodiment is described in conjunction with the 17th bid section of the second phase of Beijing Metro Line 10. The project adopts the shield tunneling method, the cutting footage per revolution h=40mm, the soil friction angle φ=30°, the soil cohesion c=0.03MPa, the soil bin pressure p=0.3MPa, and the cutting angle α=75° , blade angle β=60°, cutter length l=135mm, cutter width b=40mm, friction coefficient between cutter and soil μ 0 =0.4, the friction coefficient μ between soil 1 =0.3, energy wear rate I=5.5×10 -6 mm 3 / J. The following will take the excavation distance S = 1550m, and install the cutting knife with radius R = 3.05m as an example, and give the detailed steps for calculating the wear amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com