Simulation method of shield tunnel joint structure

A simulation method and technology for shield tunneling, applied in the field of simulation of shield tunnel joint structure, can solve problems such as large errors in lining structure, inability to reasonably describe joint deformation characteristics, and difficulty in determining joint simulation parameters, and achieve reasonable calculation results. , the effect of reasonable reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

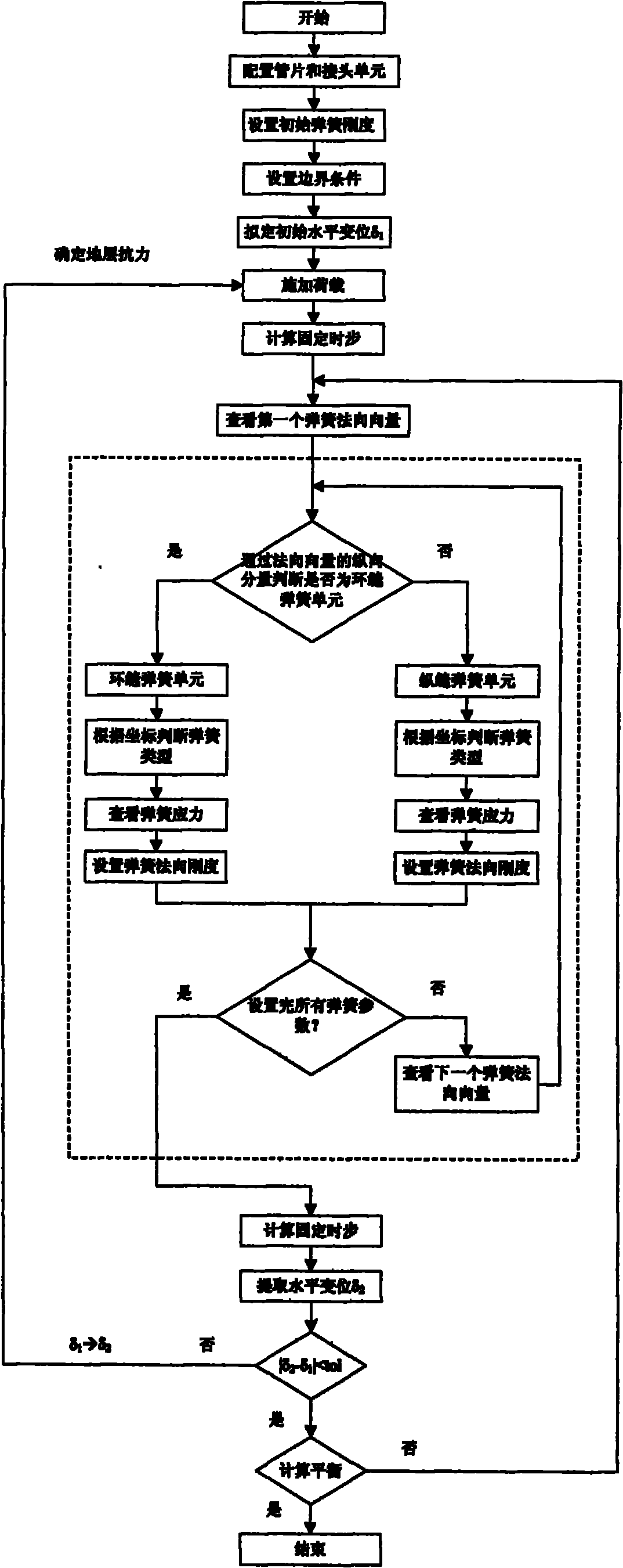

[0043] see figure 1 , the implementation steps are as follows:

[0044] (1) start;

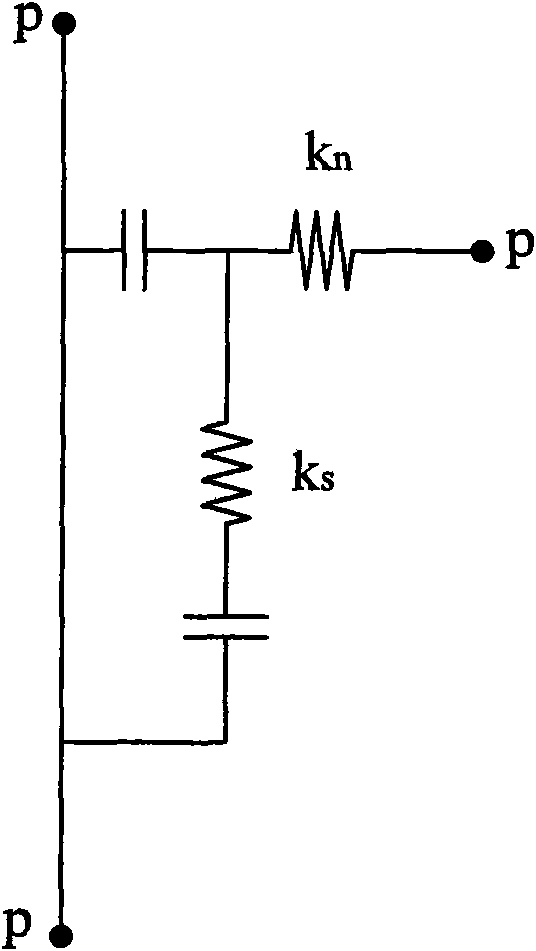

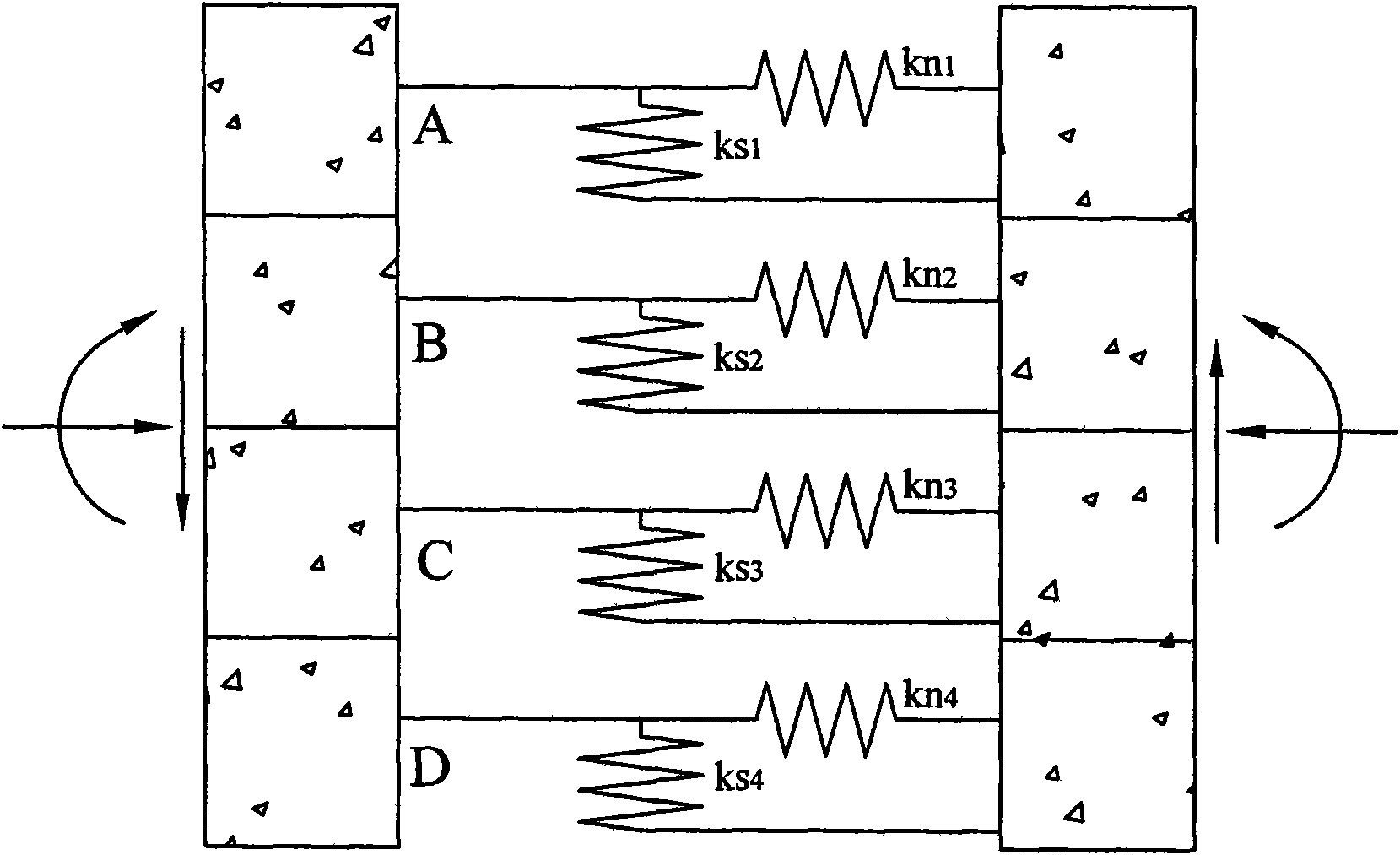

[0045] (2) Set up the joint unit, using four sets of springs to simulate the four-layer structure of the segment. From the inside to the outside, the first layer of springs simulates the inner force transmission liner D, the second layer of springs simulates bolts C, and the third layer of springs simulates the outer force transmission liner Pad B, the fourth layer of springs simulates elastic gasket A, each group of springs includes multiple sub-springs, the number of sub-springs in the circumferential direction can be determined according to the size of the segment and the calculation accuracy, and the number in the axial direction is also determined by the calculation accuracy;

[0046] (3) Set the initial spring stiffness, including normal stiffness and shear stiffness, set the boundary conditions according to the actual conditions, and draw up the initial displacement of the joint δ 1 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com