Stitch welding machine establishment benchmark simulation system, benchmark establishment method and stitch welding machine

A technology for establishing benchmarks and simulation systems, applied to welding equipment, auxiliary devices, instruments, etc., can solve problems such as waiting for stringer, typesetting and switching to complete, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

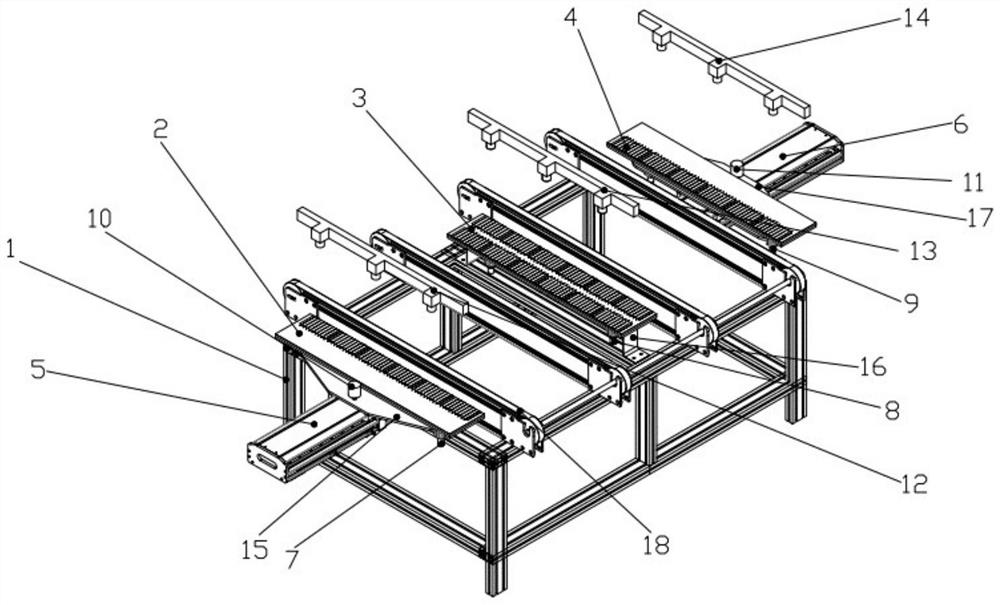

[0031] An embodiment of the present invention, such as figure 1 As shown, a kind of stitch welding machine establishment benchmark simulation system (hereinafter referred to as "simulation system") is disclosed, including a pipeline frame 1, a normalization module, an LED display screen and an image system, and the normalization module and the LED display screen are installed on On the assembly line frame 1, the LED display can display the position information of the photovoltaic module that needs to switch the version. Anyway, the module can drive the LED display to move, and the imaging system is located above the LED display to take pictures of the LED display.

[0032] In this embodiment, when the version needs to be switched, the position parameters of the battery string are set by the host computer and displayed on the LED display, and the normalization module moves the LED display according to the length and size of the photovoltaic module that needs to be switched. Mak...

Embodiment 2

[0054] An embodiment of the present invention discloses a method for establishing a benchmark of a stitch welding machine, using the stitch welding machine of Embodiment 1 to establish a benchmark simulation system, including the following steps:

[0055] Step 1: Lift the LED display to the upper position;

[0056] When switching the version, the jacking cylinder lifts the LED display to the upper position, simulating the height of the photovoltaic module after docking on the assembly line frame 1.

[0057] Step 2: Normalize the module to drive the LED display to simulate the length of the photovoltaic module;

[0058] After the LED display is lifted into place, enter the version information to be switched on the host computer, including the protruding length of the battery string head and tail ribbon, the distance between the battery strings, the distance between the battery string and the glass edge of the photovoltaic module, and the length of the photovoltaic module Wait....

Embodiment 3

[0063] An embodiment of the present invention discloses a stitch welding machine, including the stitch welding machine establishment benchmark simulation system described in Embodiment 1, before the stitch welding machine produces a new type of photovoltaic module, the stitch welding machine is used to establish a benchmark The simulation system switches the version.

[0064] Compared with the prior art, the beneficial effects of the stitch welding machine provided in this embodiment are basically the same as those of the welding head temperature measuring device of the stitch welding machine provided in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com