Multidirectional operation platform for electric power overhaul

A technology for electric power maintenance and operating platforms, which is applied to lifting devices, buildings, ladders, etc., can solve problems such as wasting time, limited directionality of maintenance platforms, and increased labor load of electric power maintenance personnel, so as to improve multi-directional position adjustment and efficient maintenance operation and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

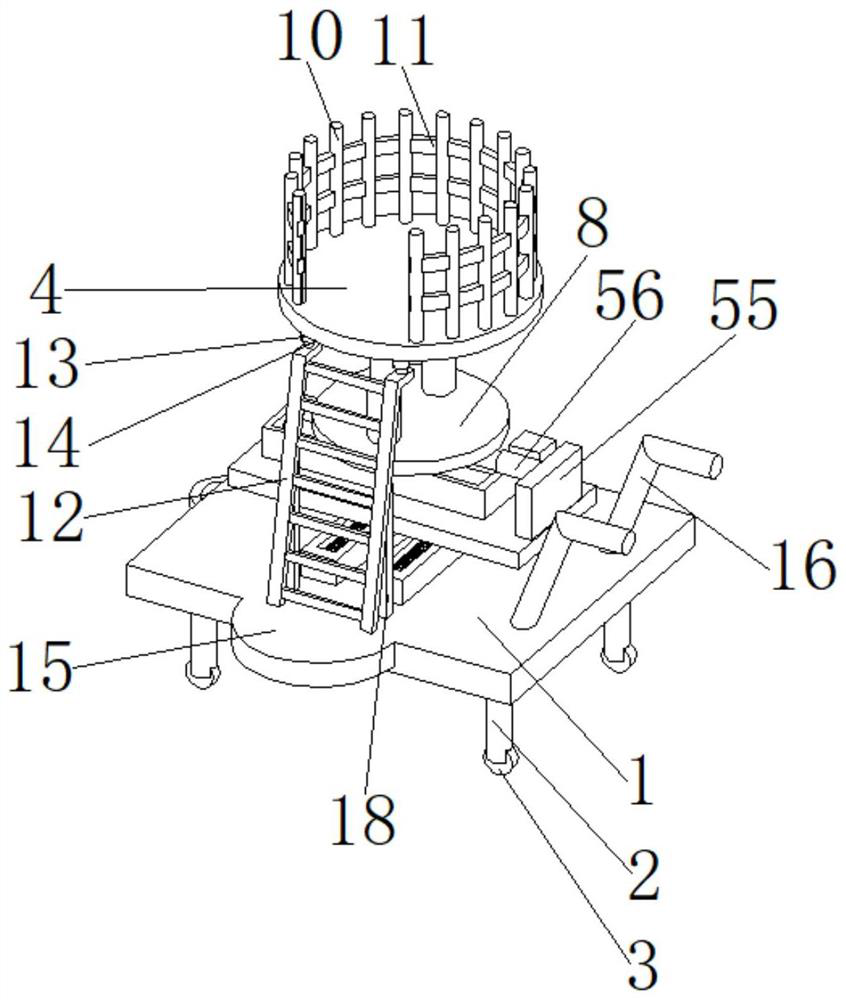

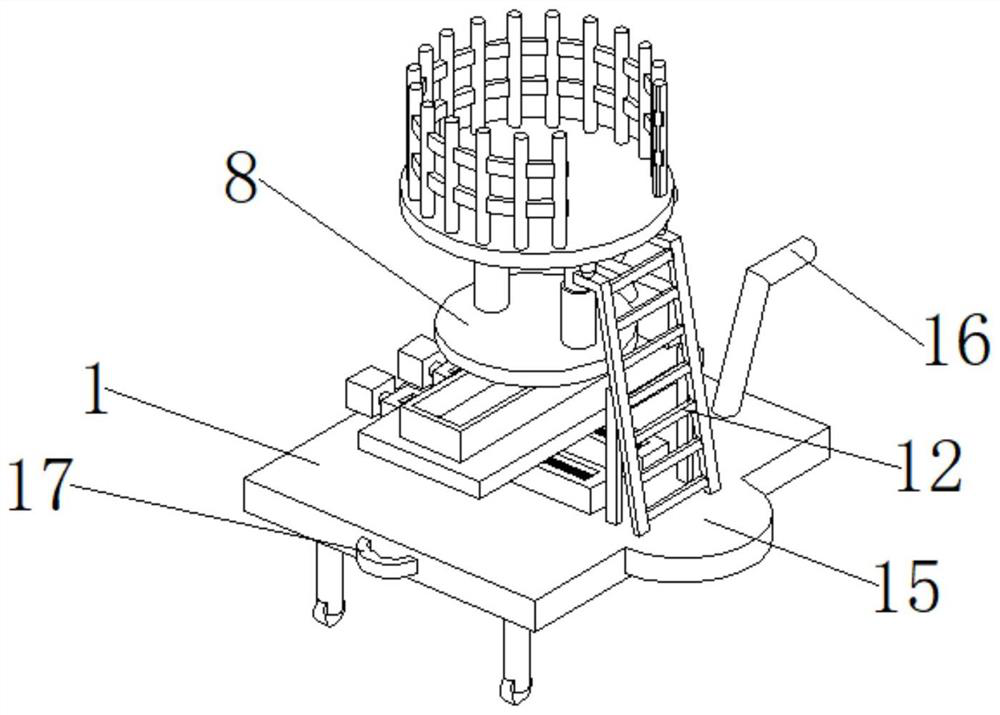

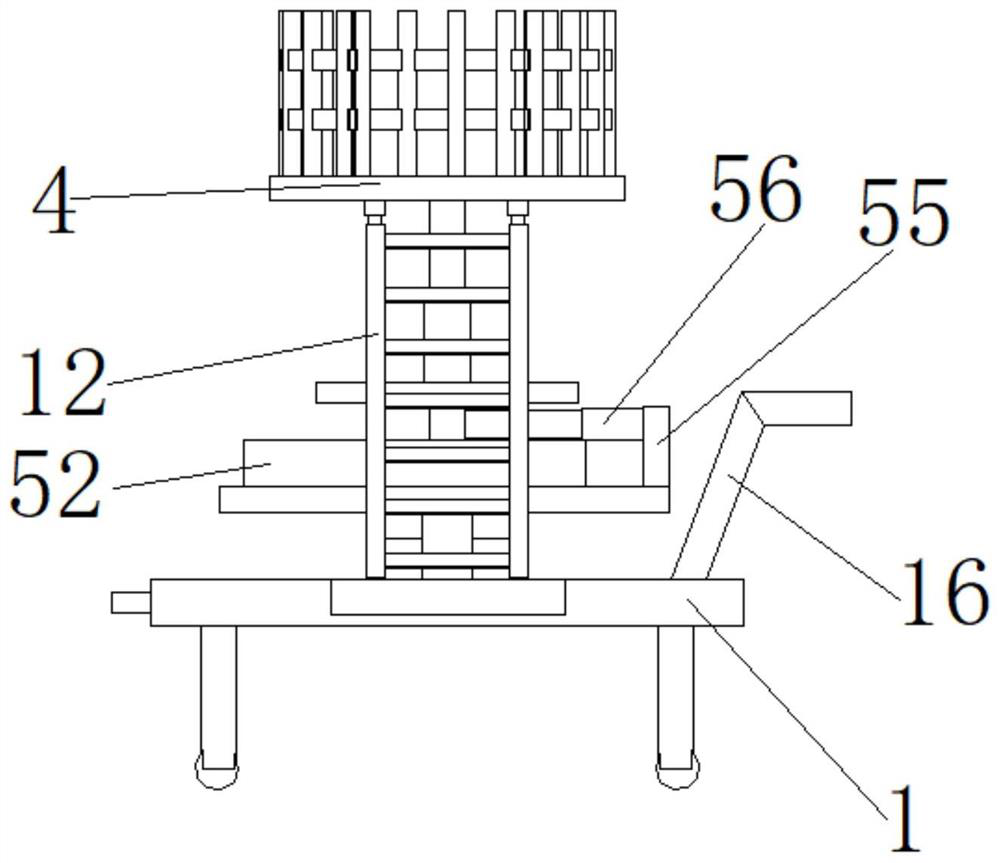

[0022] Example 1: See Figure 1-4 , the present invention provides a technical solution: an operating platform for multi-directional power maintenance, including a base plate 1, the lower surface of the base plate 1 is evenly distributed with pillars 2, and the lower end of the pillar 2 is provided with a universal locking wheel 3, by setting the universal The locking wheel 3 facilitates the movement of the operating platform. One end of the base plate 1 is provided with a push rod 16, which is convenient for manpower to pull the platform to move in a small distance. The other end of the base plate 1 is provided with a hanging ring 17. The setting of the hanging ring 17 is convenient for pulling vehicles Hang on the hanging ring 17 by the hook and drag this platform to move, the top of the base plate 1 is provided with an inspection platform 4, and the lower end of the inspection platform 4 is provided with a lifting mechanism 7 to control its lifting. Preferably, the lifting m...

Embodiment 2

[0024] Embodiment 2: The difference from Embodiment 1 is that there are gear rods 10 evenly distributed on the outer surface of the maintenance platform 4, and the gear rods 10 are connected by annular reinforcing rods 11, and there is a gap on one side of the maintenance platform 4. The gap corresponds to the position of the ladder 12 arranged on the base plate 1. The upper end of the ladder 12 is provided with a limit column 14, and the lower end of the maintenance platform 4 is provided with a sleeve 13 corresponding to the position of the limit column 14. The limit column 14 is connected to the sleeve. The cylinder 13 is matched, and the cooperation of the limit post 14 and the sleeve 13 is convenient to make the notch of the ladder 12 face the top of the ladder 12, which is convenient for the rapid positioning of the maintenance platform 4. One side of the ladder 12 is provided with a pedal 15, and the pedal 15 and the The bottom plate 1 is integrally connected, and a brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com