High-temperature-resistant recycled PET plastic particle

A technology of plastic particles and high temperature resistance, applied in the fields of organic chemistry, compounds of Group 5/15 elements of the periodic table, chemical instruments and methods, etc. problem, to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

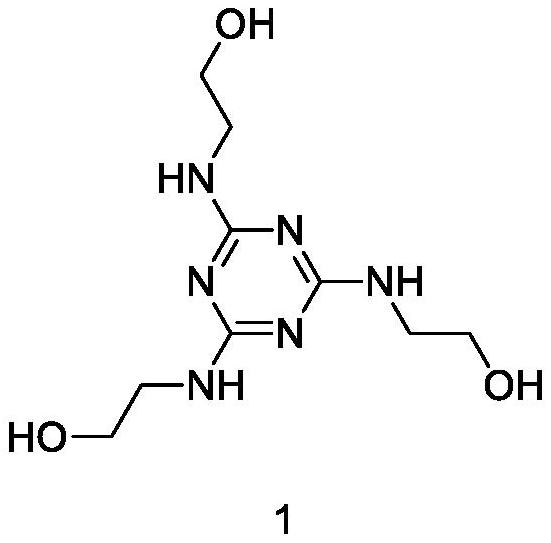

[0036] Preparation aids:

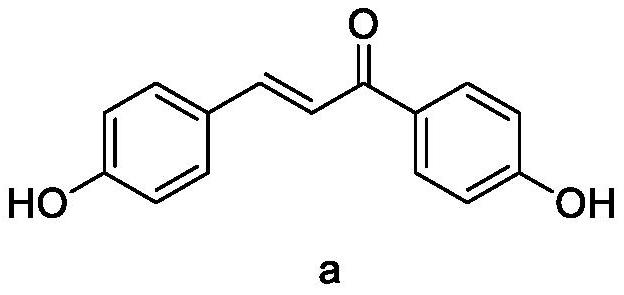

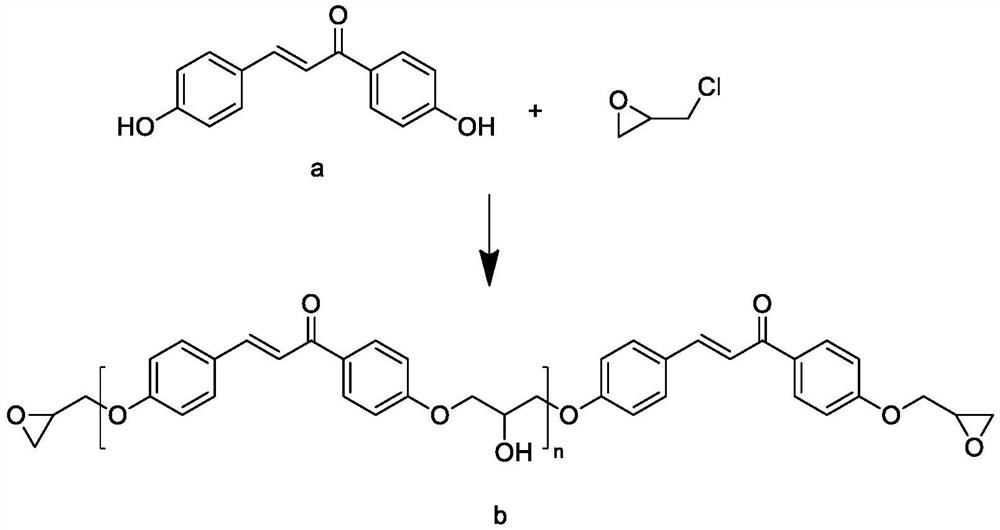

[0037] Step S21, adding p-hydroxyacetophenone and p-hydroxybenzaldehyde into absolute ethanol, then adding hydrochloric acid solution, stirring and reacting for 12 hours at a temperature of 20°C, and then heating under reflux for 3 hours. After the reaction, the obtained The reaction solution was mixed with deionized water, filtered, and dried to obtain intermediate a; wherein, the mass fraction of hydrochloric acid solution was 37%, and the molar ratio of p-hydroxyacetophenone and p-hydroxybenzaldehyde was 1:1; The dosage ratio of ketone, absolute ethanol and hydrochloric acid solution is 1g: 30mL: 0.2mL;

[0038] Step S22, mix intermediate a, epichlorohydrin and benzyltriethylammonium chloride, stir and react at 80°C for 4h, after the reaction, cool down to 60°C, then add sodium hydroxide, stir Reaction 4h, after reaction finishes, cool to room temperature, decompression concentration removes solvent, obtains polymer b; Wherein, the mass ratio of ...

Embodiment 2

[0041] Prepare enhancer:

[0042]Step S11: Heat the glass fiber at 400°C for 1 hour, then mix it with the silane treatment liquid, stir for 2 hours under nitrogen protection at a temperature of 70°C, then filter and wash with absolute ethanol. Dry to constant weight at ℃ to obtain primary modified fiber; wherein, the silane treatment liquid is N-(2-aminoethyl)-3-aminopropyltrimethoxysilane and deionized water mixed according to the dosage ratio of 3g:100mL made,

[0043] Step S12, mix the primary modified fiber with glacial acetic acid, then add additives, stir and react at 20°C for 60 minutes, then raise the temperature to 120°C, and react for 5 hours. After the reaction, cool to room temperature, filter, and use Wash with ionic water until the washing solution is neutral to obtain the enhancer. Wherein, the dosage ratio of primary modified fiber, auxiliary agent and glacial acetic acid is 12g:18g:300mL, and the auxiliary agent is prepared in Example 1.

Embodiment 3

[0045] Prepare enhancer:

[0046] Step S11: Heat the glass fiber at 400°C for 1 hour, then mix it with the silane treatment liquid, stir for 2 hours under nitrogen protection at a temperature of 70°C, then filter and wash with absolute ethanol. Dry to constant weight under the condition of ℃ to obtain the primary modified fiber; wherein, the silane treatment solution is N-(2-aminoethyl)-3-aminopropyltrimethoxysilane and deionized water mixed according to the dosage ratio of 5g:100mL made,

[0047] Step S12, mix the primary modified fiber with glacial acetic acid, then add additives, stir and react at 20°C for 60 minutes, then raise the temperature to 120°C, and react for 8 hours. After the reaction, cool to room temperature, filter, and use Wash with ionic water until the washing solution is neutral to obtain the enhancer. Wherein, the dosage ratio of primary modified fiber, auxiliary agent and glacial acetic acid is 12g:18g:300mL, and the auxiliary agent is prepared in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com