Jet reverse thrust runner structure

A runner and anti-thrust technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of jet reverse thrust runner disintegration, damage to generator sets, circumferential asymmetry, etc., to avoid torque loss, Effect of reducing resistance torque and highlighting rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

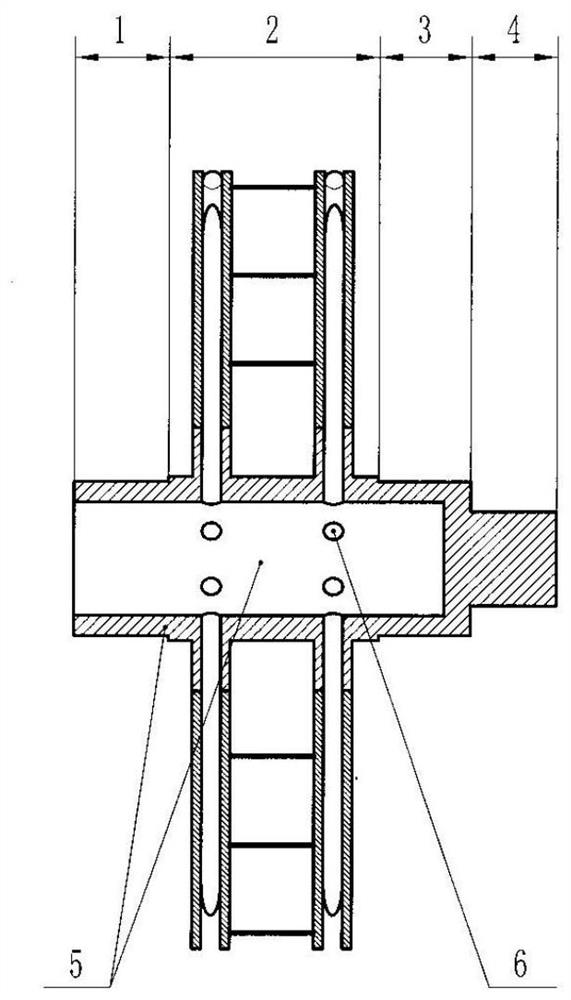

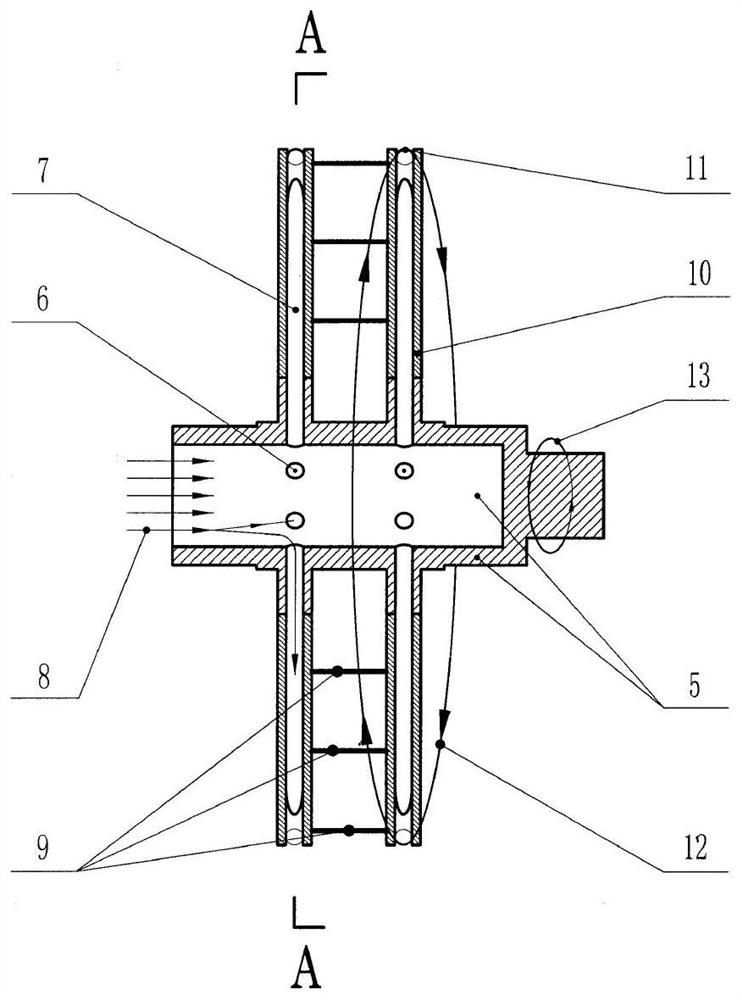

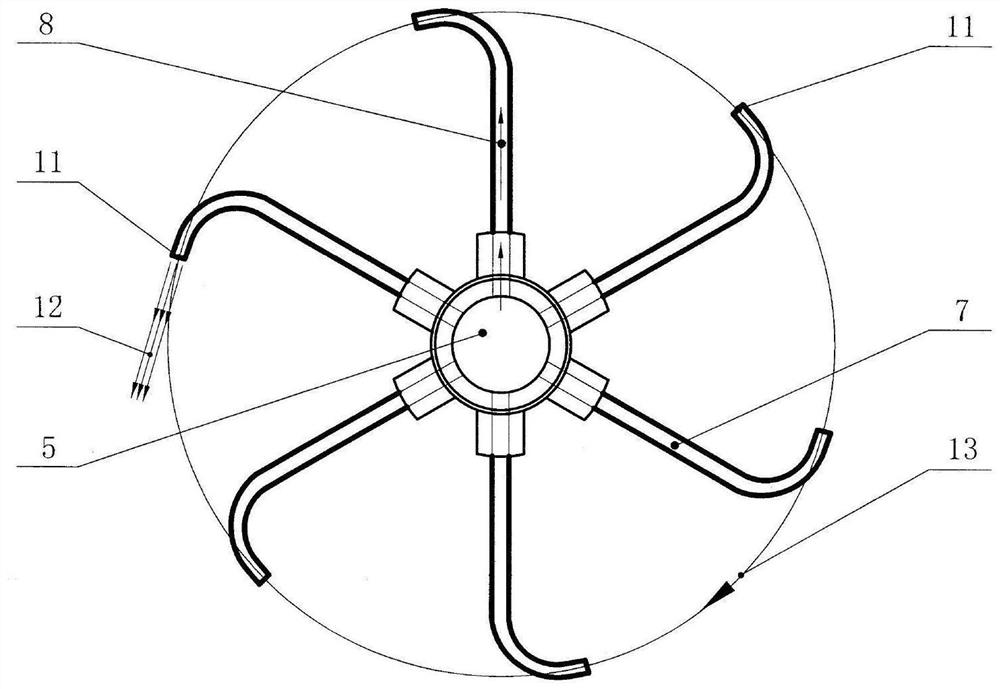

[0029] see Figure 1-Figure 5 , is an embodiment of a jet reverse thrust runner structure of the present invention.

[0030] exist figure 1 Among them, the supporting section 1 at the open end of the hollow shaft, the supporting section 3 at the tail end of the hollow shaft and the torque output connecting section 4 are mainly used to support, seal and connect the engine shaft; the middle of the two supporting sections is the torque generating section 2, which mainly functions It is fixedly connected with the tubular anti-thrust arm 7. Since the functional structures of these four functional segments have become universally known structures, they are only represented by segments in the accompanying drawings of the present invention.

[0031] exist figure 2 In the shown embodiment, the supporting section 1 at the open end of the hollow shaft, the torque generating section 2, the supporting section 3 at the tail end of the hollow shaft and the torque output connection sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com