Ship direct-current cable laying structure

A DC cable, ship technology, applied in cable laying equipment, electrical components and other directions, can solve problems affecting the operation of its own equipment, affecting the operation of electronic equipment, affecting the operation of ship electrical equipment, etc., to achieve the effect of eliminating electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

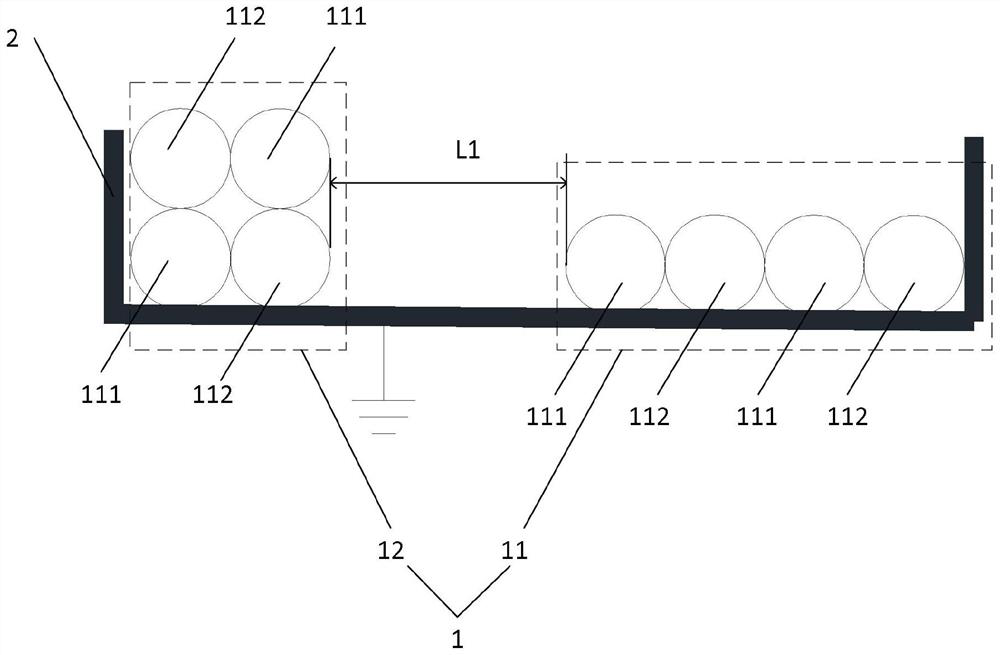

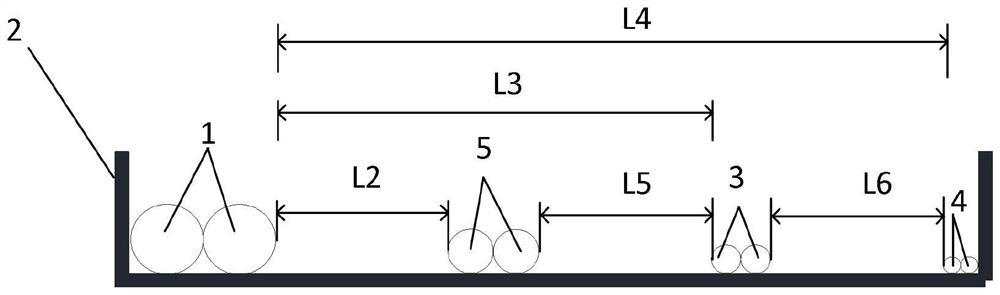

[0035] figure 1 It is a structural schematic diagram of the ship DC cable laying structure shown in the embodiment of the present application.

[0036] see figure 1 , the ship's DC cable laying structure includes a propulsion power cable bundle 1 and a cable bracket 2, the propulsion power cable bundle 1 includes a first propulsion power cable bundle 11, and the first propulsion power cable bundle 11 includes at least two groups of DC cable bundles, each group The DC cable bundle includes a positive DC cable 111 and a negative DC cable 112, and each group of DC cable bundles is laid side by side in the order of arrangement from the positive DC cable 111 to the negative DC cable 112, or from the negative DC cable 112 to the positive DC cable 111. On the cable tray 2, two adjacent groups of DC cable bundles are close to each other and arranged in the same order.

[0037] In this embodiment, the laying method of the first propulsion power cable bundle 11 on the cable bracket 2 ...

Embodiment 2

[0042] In practical applications, on the basis of the first embodiment, each group of DC cable bundles can also be stacked on top of each other.

[0043] see figure 1The propulsion power cable bundle 1 also includes a second propulsion power cable bundle 12, the second propulsion power cable bundle 12 includes at least two groups of DC cable bundles, and each group of DC cable bundles is arranged according to the order of positive DC cables 111 to negative DC cables 112, Or the negative DC cable 112 to the positive DC cable 111 are arranged side by side and stacked on the cable bracket 2 , two adjacent DC cable bundles are close to each other and the arrangement sequence is reversed.

[0044] In this embodiment, the laying method of the second propulsion power cable bundle 12 on the cable bracket 2 is as follows: the positive DC cables 111 and the negative DC cables 112 in the first group of DC cable bundles are laid sequentially on the bottom layer, and the second The DC cab...

Embodiment 3

[0050] In practical applications, on the basis of the above embodiments, in order to prevent electromagnetic interference between the propulsion power cable bundles, a certain distance needs to be kept between the propulsion power cable bundles.

[0051] see figure 1 , the distance L1 between the first propulsion power cable bundle 11 and the second propulsion power cable bundle 12 is greater than 20 mm.

[0052] It should be noted that each propulsion power cable bundle 1 may only include one or more first propulsion power cable bundles 11 or second propulsion power cable bundles 12, or may include first propulsion power cable bundles 11 and second propulsion power cable bundles 12. The combination of the cable bundles 12 is not limited here. In this embodiment, the propulsion power cable bundle 1 includes a first propulsion power cable bundle 11 and a second propulsion power cable bundle 12 .

[0053] In addition, when there are only first propulsion power cable bundles 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com