Inflatable unfolding semi-rigid sealed cabin adopting compressible multi-layer sandwich protective layer

An inflatable deployment and protective layer technology, applied in the field of spacecraft structure, can solve the problems of difficult folding of the inflatable cabin, difficulty in deployment control, and large deployment friction, so as to achieve smooth deployment process, simple deployment drive and control method, and deployment friction small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

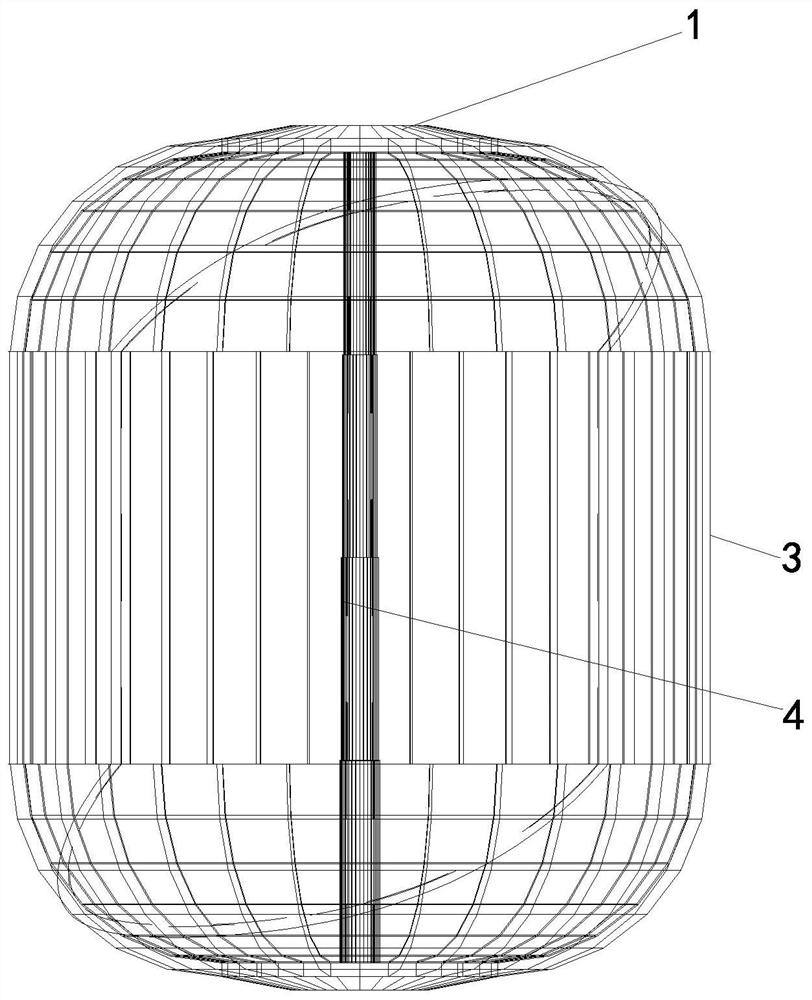

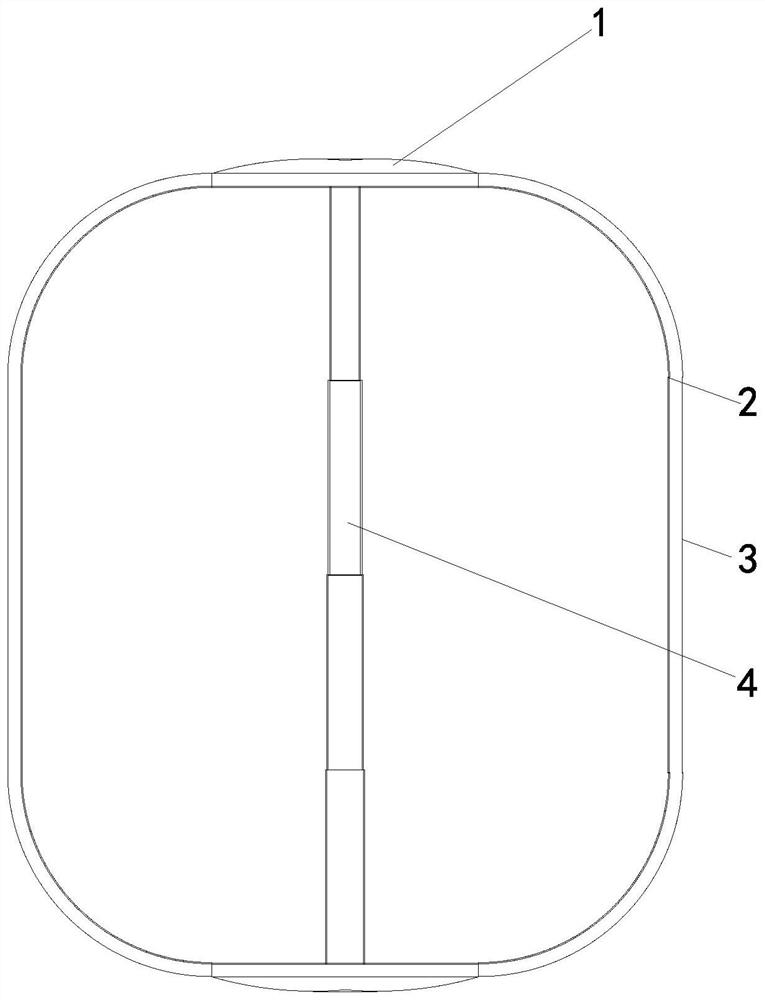

[0031] Specific implementation mode one: refer to Figure 1 to Figure 11 Describe this embodiment. This embodiment provides an inflatable and deployed semi-rigid airtight capsule using a compressible multi-layer sandwich protective layer, including a sealed pressure-bearing inner bag 2, a space environment protection layer 3, and an auxiliary deployment multi-stage sleeve 4 and two rigid heads 1; the two rigid heads 1 are arc-shaped metal structures located at both ends of the inflated and expanded semi-rigid airtight cabin (inflatable cabin), between the edges of the two rigid heads 1 The space is connected with the sealed pressure-bearing inner bag 2 and the space environment protection layer 3, so that the middle section of the inflatable cabin is cylindrical, and the upper and lower ends are hemispherical. 4, the sealed pressure-bearing inner bag 2 is set inside the space environment protection layer 3.

specific Embodiment approach 2

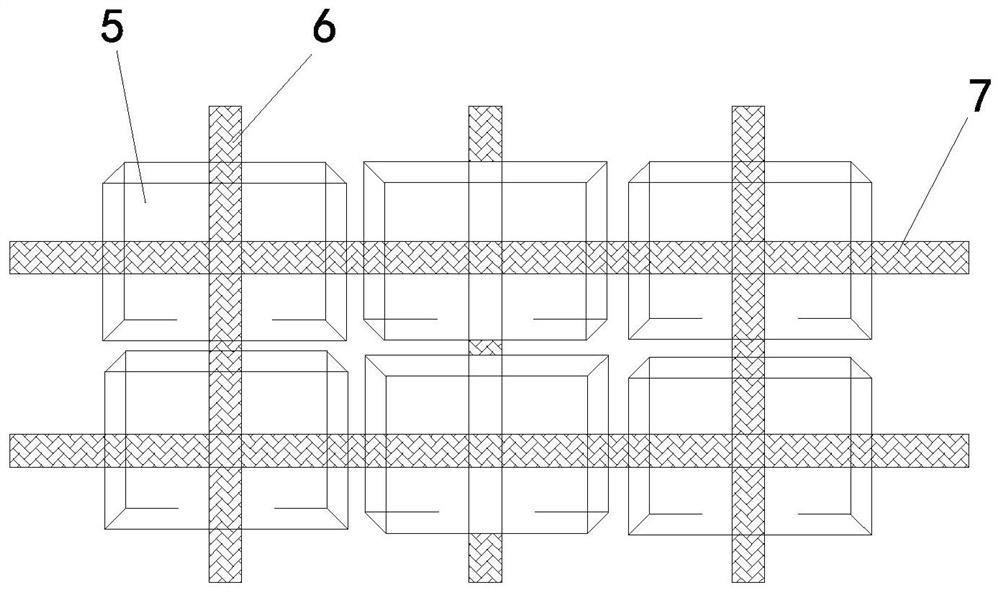

[0032] Specific implementation mode two: refer to Figure 2 to Figure 9 Describe this embodiment, this embodiment is to further limit the specific embodiment one, in this embodiment, the space environment protection layer 3 is composed of a plurality of rigid compressible multi-layer sandwich modules 5, a plurality of flexible connecting strips-6 Composed of a plurality of flexible connecting strips 27, the inflatable cabin is easy to fold and expand when inflated. The plurality of rigid and compressible multi-layer sandwich modules 5 are evenly arranged along the outer surface of the sealed pressure-bearing inner bag 2, and in the circumferential direction Folding is carried out in an overlapping manner, connected by flexible connecting strips 2 7 , and folded axially in an interspersed manner, connected by flexible connecting strips 1 6 . Lock the folded inflatable bulkhead package tightly. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific implementation mode three: refer to Figure 4 to Figure 6 Describe this embodiment, this embodiment is to further limit the second specific embodiment, in this embodiment, the rigid compressible multi-layer sandwich module 5 located in the cylindrical section of the space environment protection layer 3 is a trapezoidal structure, located in the space environment protection layer 3. The circumferential length of the rigid compressible multi-layer sandwich module 5 of the circular arc segment gradually decreases from the tail end to the head end. Other compositions and connection methods are the same as those in the second embodiment.

[0034] In this embodiment, if Figure 7 , Figure 8 As shown, two rigid compressible multi-layer sandwich modules 5 adjacent in the circumferential direction are set up front and back in turn, as shown in Figure 8 , the upper bottom of a trapezoidal structure on the left is set outward, and the lower bottom of the adjacent tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com