Simulation test system and test method based on top coal caving

A simulation test system and top-coal caving technology, applied in earth square drilling, mining equipment, mining equipment, etc., can solve problems such as difficult to accurately judge the boundary of coal gangue, unsatisfactory application effect, complex underground environment, etc., and achieve diverse test variables The effects of automation, precise control, and accurate prediction results

Pending Publication Date: 2022-02-11

CHINA UNIV OF MINING & TECH

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the various coal-gangue interface identification methods mentioned above have achieved certain results, due to the complexity of the underground environment, it is difficult to accurately judge the coal-gangue boundary from a single technical means, and the actual application effec

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

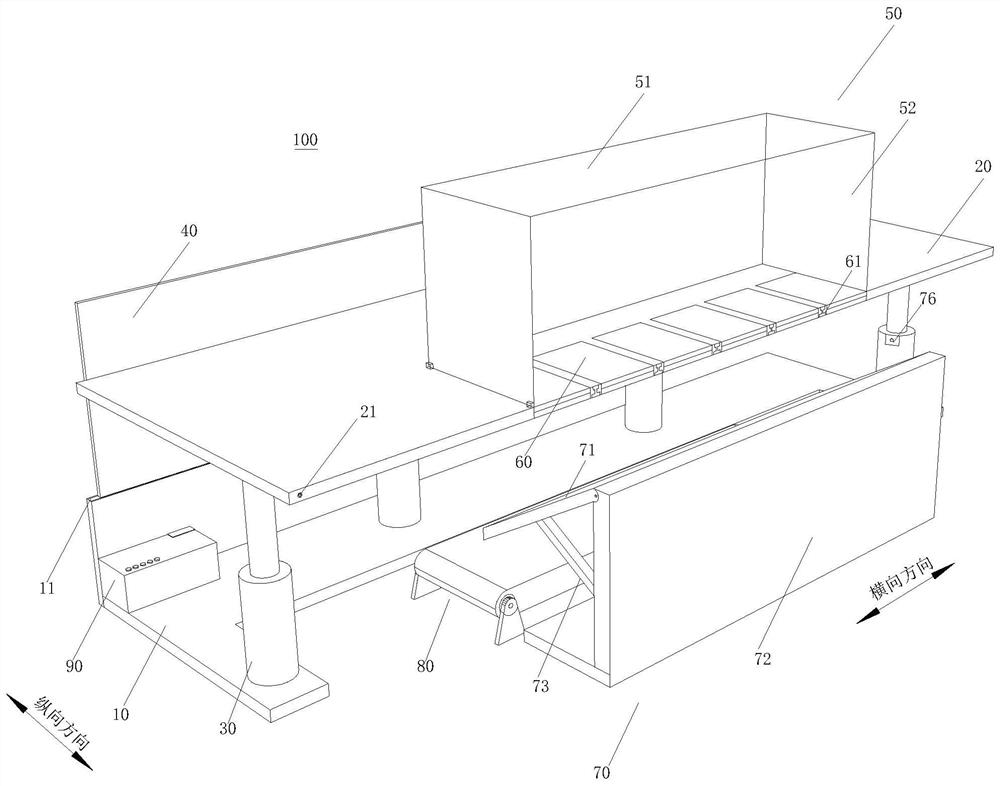

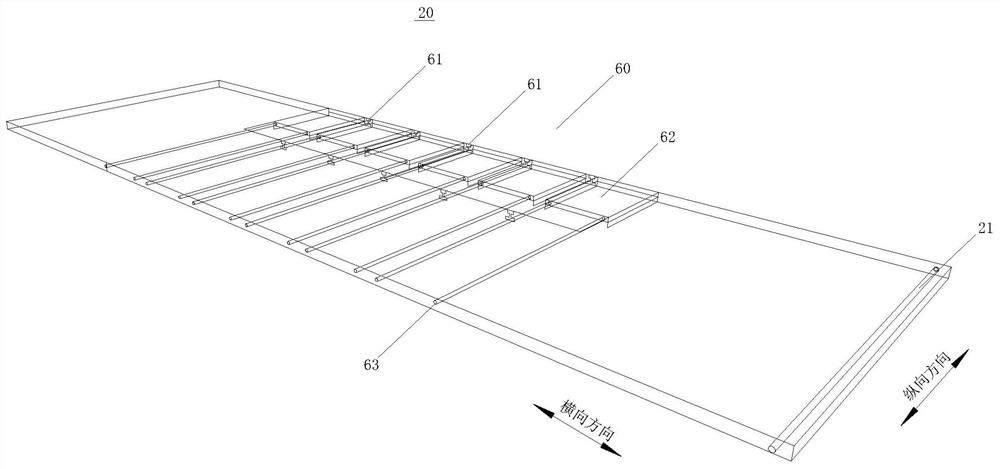

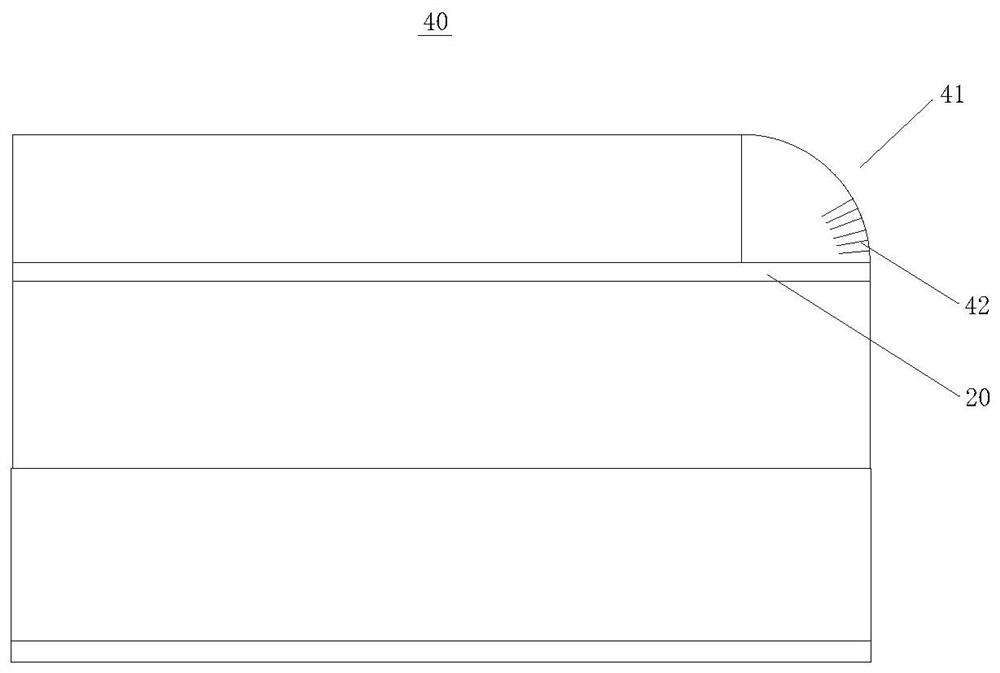

The invention discloses a simulation test system and method based on top coal caving. The simulation test system comprises a base, a platform, a storage box, pushing assemblies, a supporting assembly and a conveying assembly, wherein the platform is connected with the base through a plurality of telescopic devices, and the telescopic devices can do telescopic motion independently or synchronously; the storage box is fixedly connected to an upper end face of the platform and at least provided with a feeding port and a discharging port; the pushing assemblies are arranged in the longitudinal direction of the platform, connected with the platform in a relative movement mode and used for pushing the top coal located in the storage box out of the discharging opening, and weighing sensors used for weighing the pushed top coal are arranged on the pushing assemblies; the supporting assembly is provided with a coal blocking plate, the coal blocking plate is obliquely placed at a lower end of the discharging opening, and a vibration sensor and a sound sensor are arranged on the coal blocking plate; the conveying assembly is arranged at a lower end of the coal blocking plate and used for conveying the top coal in the transverse direction. The top coal caving simulation test system provides a theoretical basis for realizing intelligent coal caving on site.

Description

technical field [0001] The invention relates to the technical field of top-coal caving mining, in particular to a simulation test system and test method based on top-coal caving. Background technique [0002] my country's coal resources are very rich in thick coal seams, accounting for 45% of the proven coal reserves, and the output of thick coal seams accounts for 40%-50% of the total output. The rational development of thick coal seams has an important impact on the development of my country's coal industry. The top-coal caving mining method is to arrange a longwall working face with a mining height of 2m-3m along the bottom of the coal seam in the thick coal seam, and use comprehensive mechanized coal mining technology for mining, using the effect of mine pressure or supplemented by loosening blasting, etc. After the top coal is broken into bulk, it is released through the "coal discharge window" behind or above the support, and is transported out of the working face by t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F17/18E21F17/00G06F30/27

CPCE21F17/18E21F17/00G06F30/27

Inventor 吕嘉锟万志军王骏辉张源余坤师鹏张朝阳

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com