Pressurized water reactor core flow and power four-zone control method

A technology of zone control and flow zone, which is applied in the field of nuclear reactor core, can solve the problems of difficult power distribution and flow control process, matching deviation of power distribution and flow control, and reduce the extreme value of hot channel temperature, so as to improve thermal safety Margin, reduced hot aisle temperature extremes, effect of increased coolant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

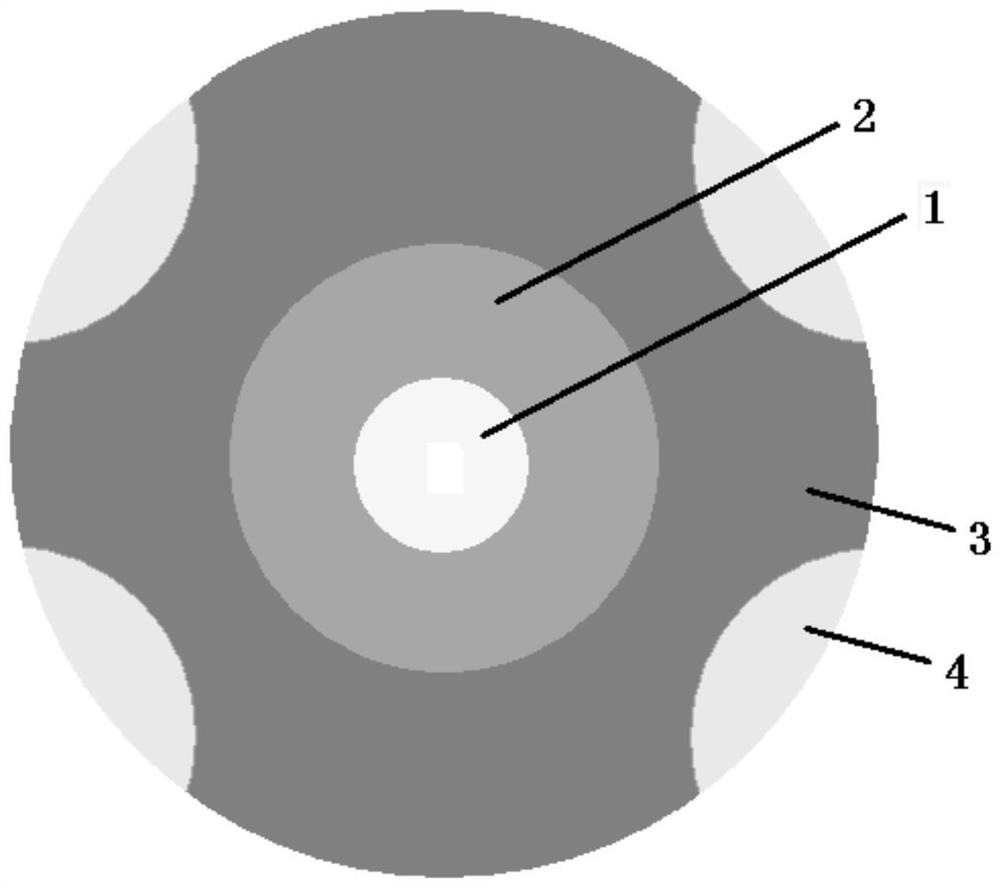

[0042] A four-zone control method for core flow and power in a pressurized water reactor, such as figure 1 As shown in the figure, the transverse section of the PWR core expands radially outwards and is sequentially provided with a first flow area 1, a second flow area 2, and a third flow area 3, the second flow area 2 wraps the first flow area 1, The third flow zone 3 surrounds the second flow zone 2 . Four fourth flow regions 4 are arranged at intervals on the edge of the third flow region 3 , and the fourth flow regions 4 are embedded toward the center of the third flow region 3 . The flow rate of the coolant in the second flow area 2 is greater than the flow rate of the coolant in the first flow area 1, the flow rate of the coolant in the first flow area 1 is greater than the flow rate of the coolant in the third flow area 3, and the third flow area The flow rate of the coolant in the flow area 3 is greater than the flow rate of the coolant in the fourth flow area 4 . It...

Embodiment 2

[0051] The difference between Example 2 and Example 1 is that: the first flow area 1 passes into the coolant with an average mass flow rate of 100% of the entire PWR core; the second flow area 2 passes into the entire PWR core with an average mass flow rate The coolant with a flow rate of 110%; the third flow zone 3 passes into the coolant with an average mass flow rate of 95% of the entire PWR core; the fourth flow zone 4 passes into the coolant with an average mass flow rate of 90% of the entire PWR core .

Embodiment 3

[0053] The difference between Example 3 and Example 1 is that: the first flow area 1 is passed into the coolant with an average mass flow rate of 110% of the entire PWR core; the second flow area 2 is passed into the entire PWR core with an average mass flow rate The coolant with a flow rate of 120%; the third flow zone 3 passes into the coolant with an average mass flow rate of 100% of the entire PWR core; the fourth flow zone 4 passes into the coolant with an average mass flow rate of 95% of the entire PWR core .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap