Multi-pole magnetic ring progressive orientation mold and orientation method thereof

A multi-pole magnetic ring, progressive technology, used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of surface magnetic tool difference, large upper and lower pole difference, etc., to achieve consistent performance, convenient control and management , the effect of orientation is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

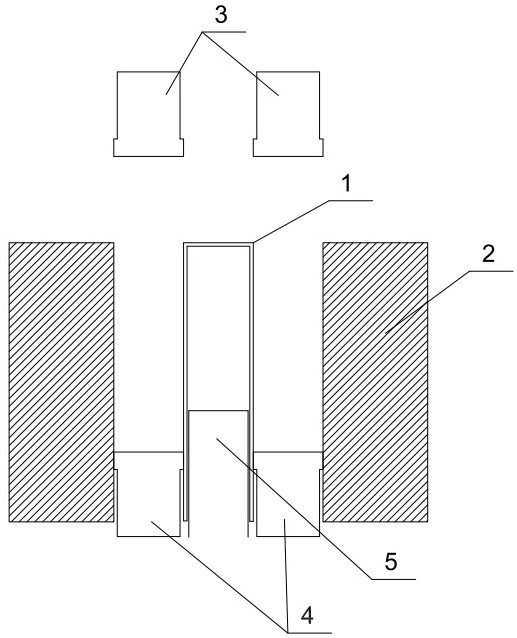

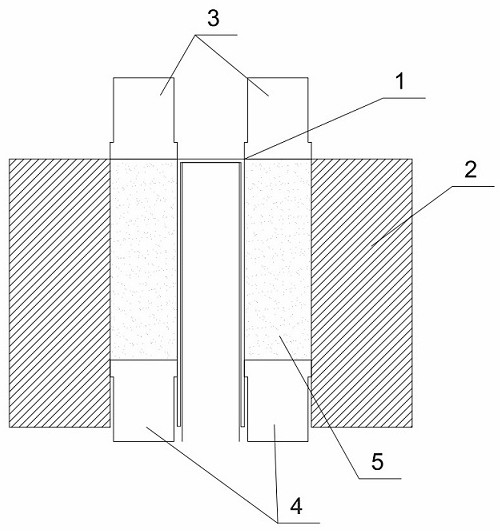

[0029] Such as Figure 1-Figure 2 As shown, the orientation step is a continuous process, Figure 1-2 It is only a schematic cut-out diagram of some representative orientation steps, and the specific orientation steps are based on the following description.

[0030] 1.1 Orientation mold

[0031] A kind of multi-pole magnetic ring progressive orientation mold provided by embodiment 1 comprises a mold core 1 and a mold sleeve 2 arranged outside the mold core 1, and there is an annular gap between the mold core 1 and the mold sleeve 2;

[0032] A cavity is provided in the mold core 1, and a movable orienter 5 is arranged in the cavity, and the orienter 5 is connected to a controller;

[0033] The upper end of the annular gap is provided with a matching upper pressure head 3, the lower end of the annular gap is provided with a matching lower pressure head 4, the outer wall of the mold core 1, the inner wall of the mold sleeve 2, the upper pressure head 3 The lower surface of th...

Embodiment 2

[0043] 2.1 Orientation mold

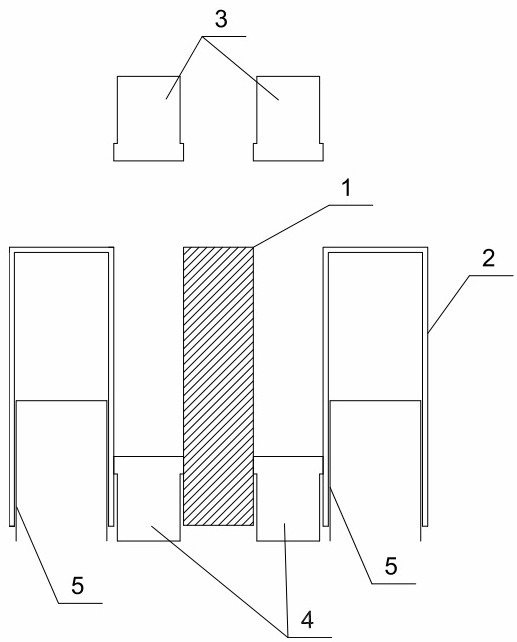

[0044] Such as image 3 as shown,

[0045] A progressive orientation mold for multi-pole magnetic rings provided in Embodiment 2 includes a mold core 1 and a mold sleeve 2 arranged outside the mold core 1, and there is an annular gap between the mold core 1 and the mold sleeve 2;

[0046] A cavity is provided in the mold cover 2, and a movable orienter 5 is arranged in the cavity, and the orienter 5 is connected to the controller;

[0047] The upper end of the annular gap is provided with a matching upper pressure head 3, the lower end of the annular gap is provided with a matching lower pressure head 4, the outer wall of the mold core 1, the inner wall of the mold sleeve 2, the upper pressure head 3 The lower surface of the lower surface and the upper surface of the lower pressure head 4 form a mold cavity.

[0048] As an optional implementation, the controller is a PLC controller.

[0049] As an optional implementation, the orienter 5 is a s...

Embodiment 3

[0057] 3.1 Orientation mold

[0058] A kind of multi-pole magnetic ring progressive orientation mold provided by embodiment 3 comprises a mold core 1 and a mold sleeve 2 arranged outside the mold core 1, and there is an annular gap between the mold core 1 and the mold sleeve 2;

[0059] Both the mold core 1 and the mold sleeve 2 are provided with a cavity, and a movable orienter 5 is arranged in the cavity, and the orienter 5 is connected to a controller;

[0060] The upper end of the annular gap is provided with an upper indenter 3 with a matching size, and the lower end of the annular gap is provided with a lower indenter 4 with a matching size. The lower surface of the lower surface and the upper surface of the lower pressure head 4 form a mold cavity.

[0061] As an optional implementation, the controller is a PLC controller.

[0062] As an optional implementation, the orienter 5 is a special orienter for multi-pole magnetic rings, and the number of poles of the special ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com