Staggered-tooth three-edge broach

A technology of three-sided blade and staggered teeth, which is applied in the design and manufacture of aeroengine tools, can solve problems such as poor strength, thin thickness, and penetration of broaches, and achieve the effect of good quality and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

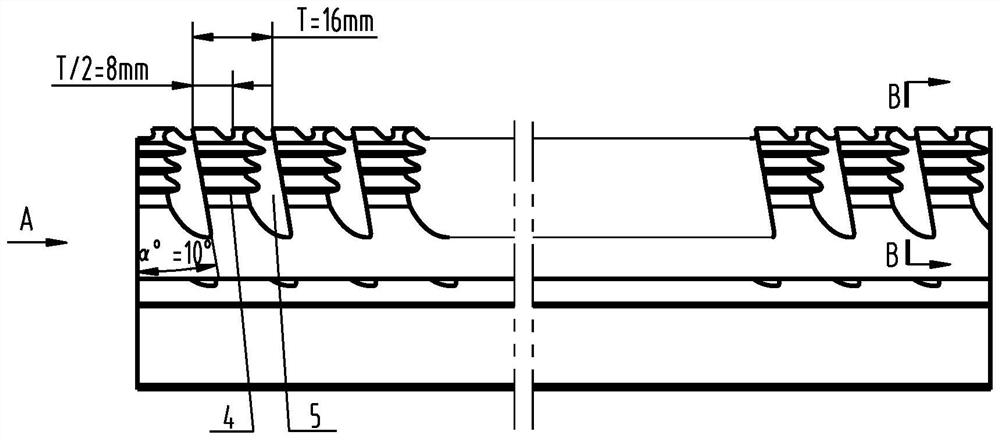

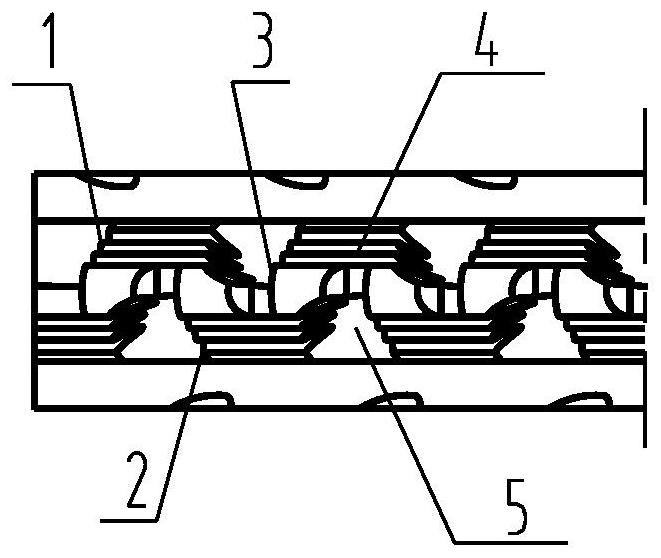

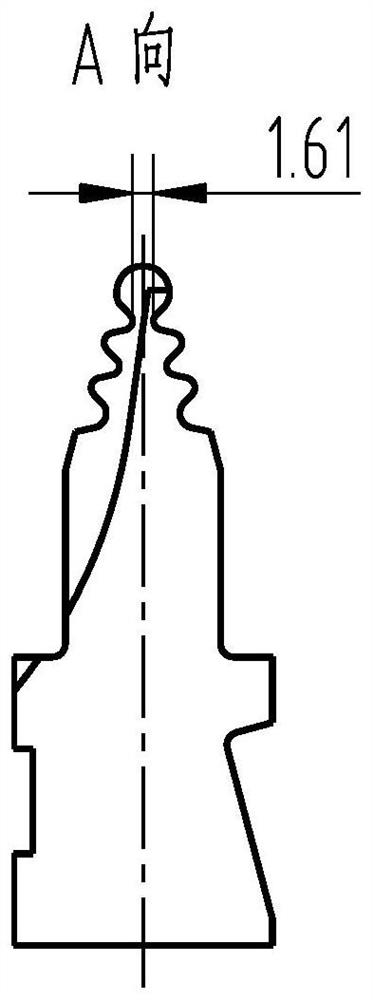

[0026] refer to Figure 1-7 , a staggered-tooth three-sided broach, including a cutter body, a plurality of side cutter teeth are respectively arranged on both axial sides of the broach, which are respectively a left cutter tooth 1 and a right cutter tooth 2, and two adjacent cutter teeth on the same side There are chip pockets 5 between the side teeth, and the chip pockets on both sides of the cutter body are arranged alternately along the axial direction of the cutter body, and the chip pockets on one side of the cutter body are located on the tooth back of the side cutter teeth on the other side of the cutter body 4, the top of the cutter body is provided with top cutter teeth 3.

[0027] The chip flutes on both sides of the cutter body are arranged alternately along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com