Fuzzy Dynamic Integral Sliding Mode Control Method for Reentrant Industrial Manufacturing Systems

An industrial manufacturing and integral sliding mode technology, applied in the field of control science and engineering, can solve the problems of unbalanced loads of multiple production scenarios, difficult to suppress nonlinear characteristics and random noise, etc., to achieve suppression of nonlinear characteristics and random noise, fast smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

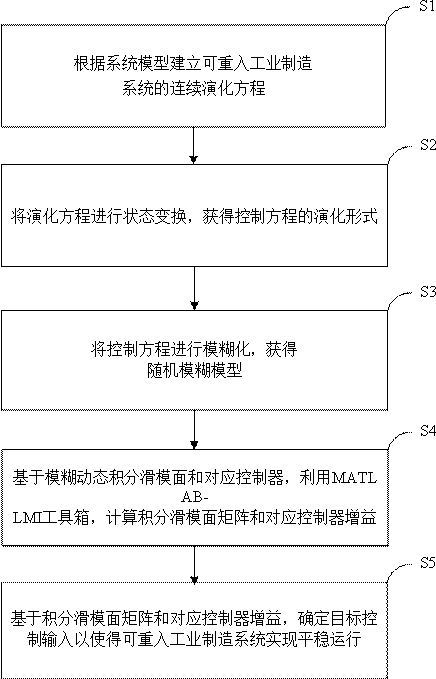

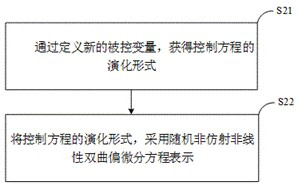

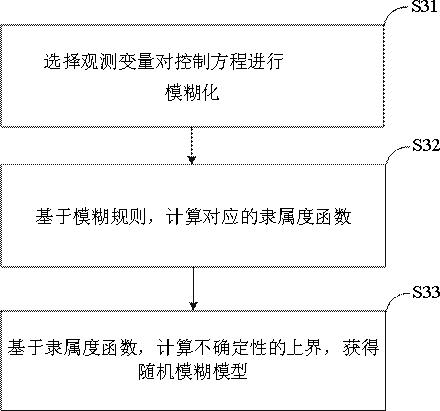

Method used

Image

Examples

Embodiment 1

[0173] First, consider the following evolution equations for reentrant industrial manufacturing systems involving 2 production scenarios:

[0174]

[0175]

[0176] in , r 1 ( x , t )and r 2 ( x , t ) are the product densities of the first and second production scenarios at each degree of completion and time, respectively, u ( x , t ) is the control input.

[0177] It can be seen that the equilibrium point of the above production scenario is r 1 ( x , t )= r 2 ( x , t )=5, u ( x , t )=0. Therefore, through the method proposed by the present invention, the following controlled variables are constructed

[0178] .

[0179] Using the modeling method of the continuous stochastic model of the control equation provided by the present invention, the evolution trend of the controlled variable can be obtained as follows:

[0180]

[0181] in,

[0182]

[0183]

[0184] is a 2-dimensional Wiener process.

[0185] The nonlinear function of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com