Spraying device for porcelain insulator production and spraying method thereof

A technology of porcelain insulator and spraying device, which is applied in the direction of spraying device and liquid spraying device, can solve the problems of uneven spraying and uneven thickness of paint, and achieve the effect of even spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

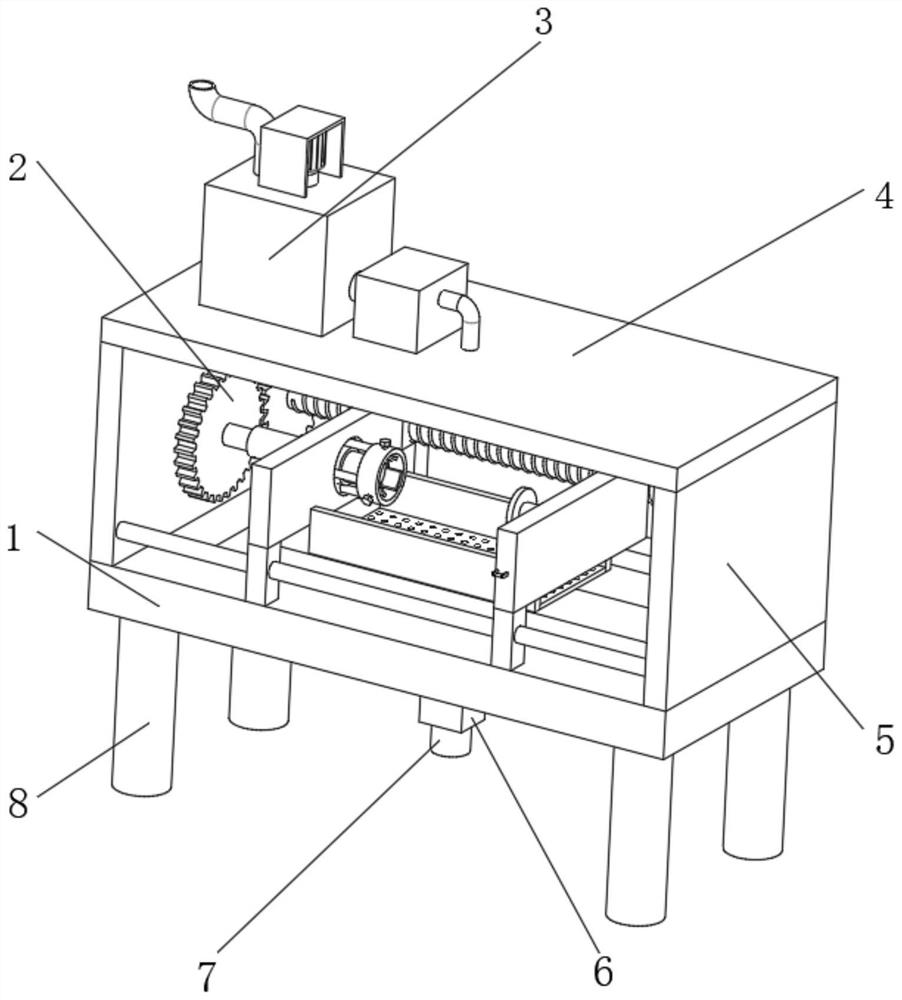

[0033] Embodiment one, by Figure 1-Figure 7 Given, the present invention includes a base plate 1, the bottom of the base plate 1 is fixedly connected with support legs 8 near the four corners, the middle of the bottom of the base plate 1 is fixedly installed with a discharge port 7, and the outer side of the discharge port 7 is fixedly mounted with a solenoid valve 6, Side plates 5 are fixedly installed on both sides of the top of the bottom plate 1, an insulator adjustment mechanism 2 is installed between the two side plates 5, the insulator adjustment mechanism 2 is located between the two side plates 5, and the tops of the two side plates 5 are fixedly installed There is a top plate 4, a spraying mechanism 3 is installed on the top of the top plate 4, a bottom groove 11 is opened on the top of the bottom plate 1, two baffles 9 are installed on the top of the bottom plate 1, and a bottom groove 11 is fixedly connected between the two baffles 9. filter plate 10 directly abov...

Embodiment 2

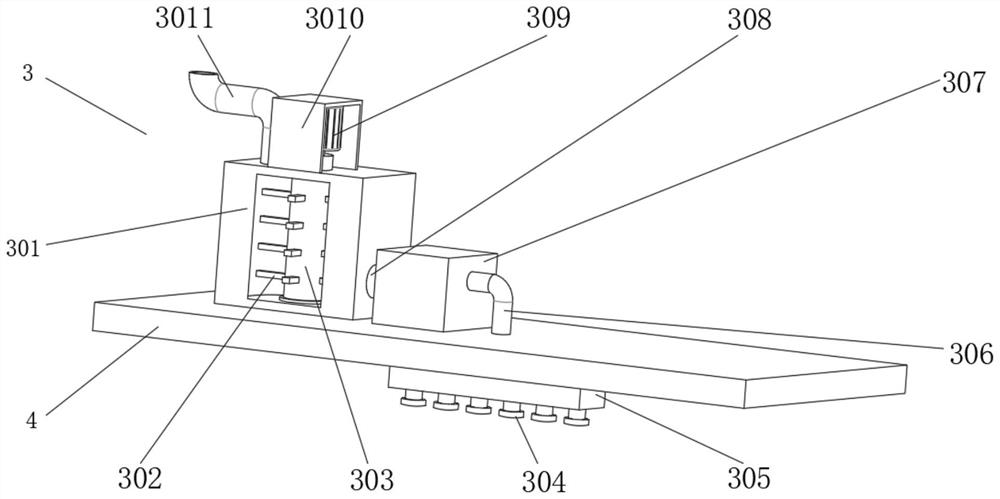

[0034] Embodiment 2, on the basis of Embodiment 1, the spraying mechanism 3 includes a U-shaped plate 3010 fixedly installed on the top of a storage box 301 fixedly connected to the top plate 4 and fixedly connected with the top plate 4, and a U-shaped plate 3010 fixedly connected to the bottom of the U-shaped plate 3010. Two motors 309, the bottom of the second motor 309 is fixedly connected with the stirring shaft 303, the bottom of the stirring shaft 303 runs through the top of the storage box 301 and extends to the bottom of the inner cavity of the storage box 301, the outside of the stirring shaft 303 is fixedly installed with equidistant Stirrer 302 located inside storage box 301, the top of storage box 301 is fixedly installed with the feeding pipe 3011 that is positioned at the left side of U-shaped plate 3010, and the right side of storage box 301 is fixedly connected with input pipe 308, and the right side of input pipe 308 A booster pump 307 is fixedly connected, the...

Embodiment 3

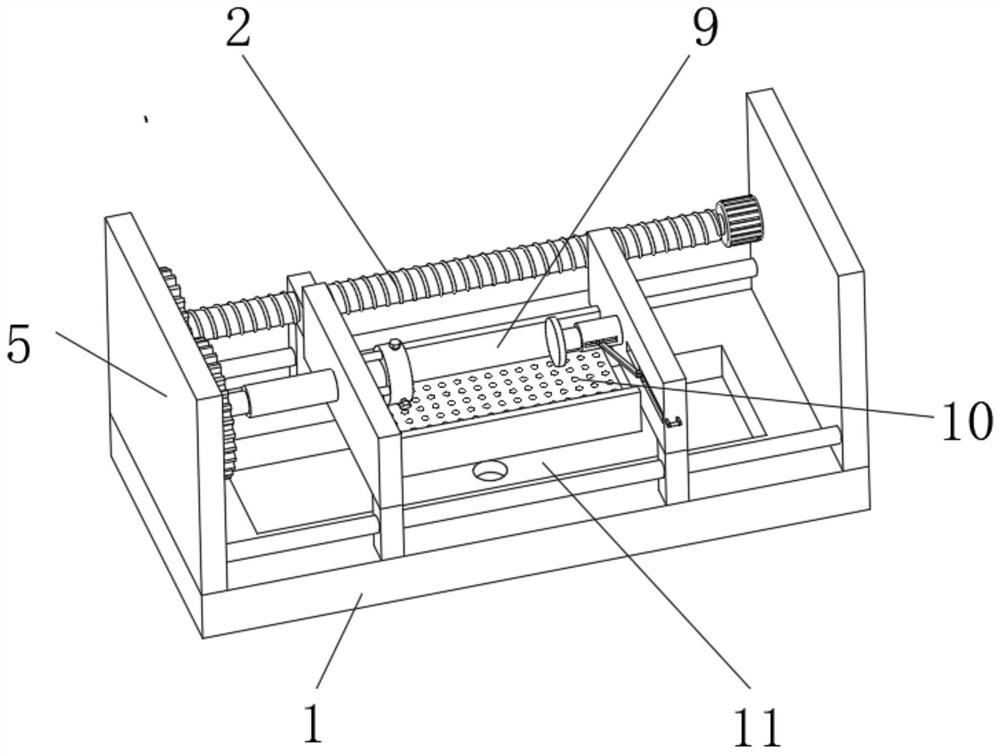

[0036] Embodiment 3. On the basis of Embodiment 1, the insulator adjustment mechanism 2 includes a first motor 201 fixedly connected to the left side of the side plate 5 located on the right side. The left side of the first motor 201 is fixedly connected to a transmission shaft 2010. The outer side of the shaft 2010 is provided with an external thread 207, the transmission shaft 2010 is threaded with two threaded sleeves 208 through the external thread 207, the left side of the transmission shaft 2010 is fixedly installed with a driving gear 209, and the two side plates 5 are fixedly connected with a Two guide posts 203, two guide blocks 204 are movably sleeved on the outside of the guide posts 203, the tops of the two guide blocks 204 on the front side are respectively fixedly connected with the left plate 2015 and the right plate 202, and the two guide blocks 204 on the rear side The top of the guide block 204 is fixedly connected with two threaded sleeves 208 respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com