Automatic loading and unloading equipment for heavy workpieces

A technology for automatic loading and unloading of materials and workpieces, which is applied in metal processing and other directions, and can solve problems such as long cantilever, workpieces cannot be placed in the fixture, and material jaws drop, so as to achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

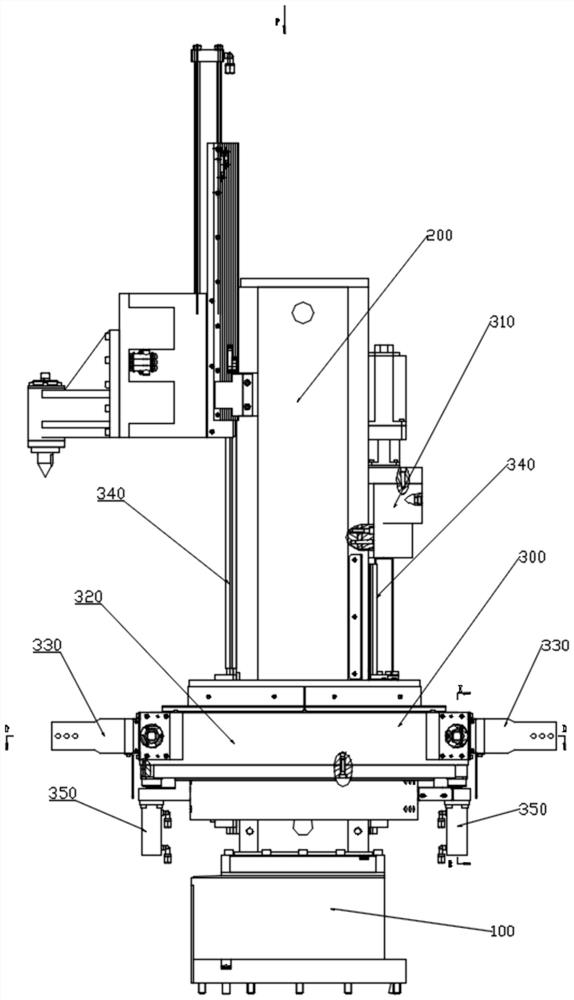

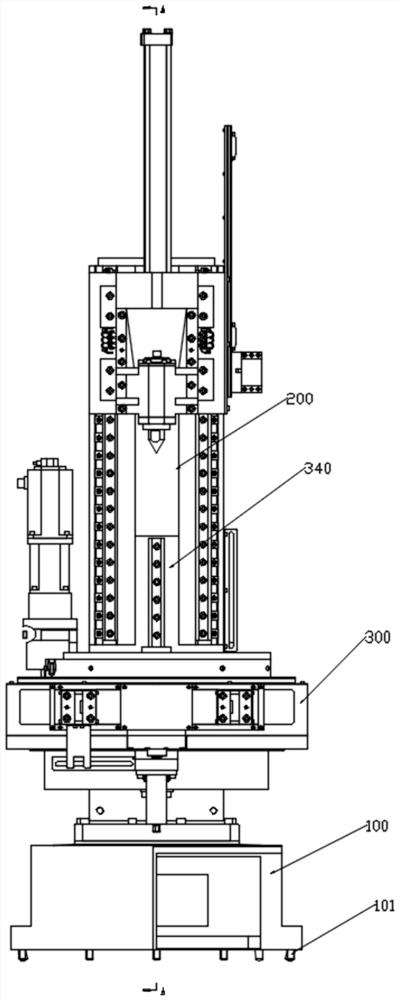

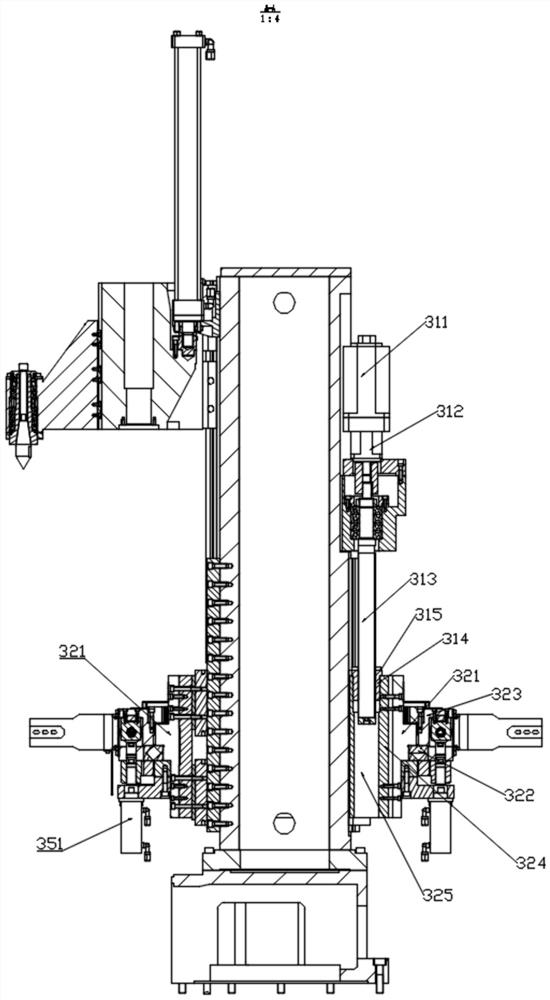

[0024] Example: such as Figure 1-6 As shown, this embodiment provides an automatic loading and unloading device for heavy workpieces, including a base 100 and a machine column 200 on the base, and a loading and unloading mechanism 300 is arranged on the machine column.

[0025] Wherein, the base has a top surface, the machine column is installed on the top surface of the base, and the bottom surface of the base is provided with wheels 101 . The machine column is a square column with four side walls. Both the base and the machine column play a supporting role.

[0026] The loading and unloading mechanism is installed on the machine column and can slide up and down along the machine column. The loading and unloading mechanism includes an up and down driving mechanism 310 , a lifting mechanism 320 and a gripping mechanism 330 . The grasping mechanism is connected with the lifting mechanism, and the lifting mechanism is connected with the up and down driving mechanism. It als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com