Tower drum welding seam inspection robot and control method thereof

A technology of robots and wall-climbing robots, which is applied in the direction of program-controlled manipulators, manipulators, motor vehicles, etc., can solve problems affecting inspection accuracy and achieve the effects of improving accuracy, ensuring accuracy, and ensuring inspection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

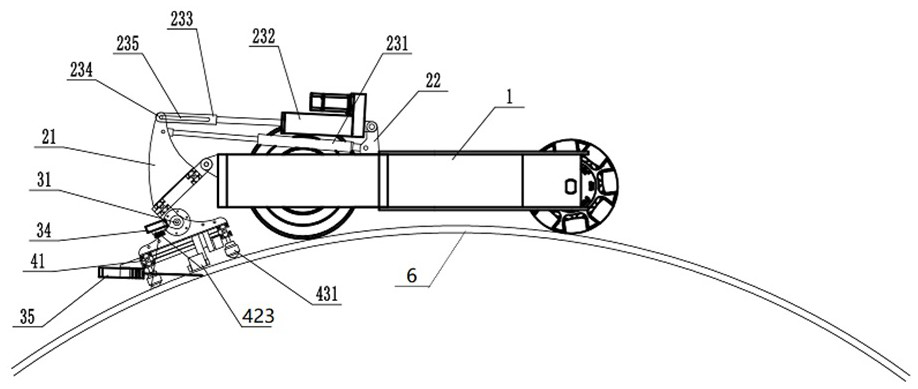

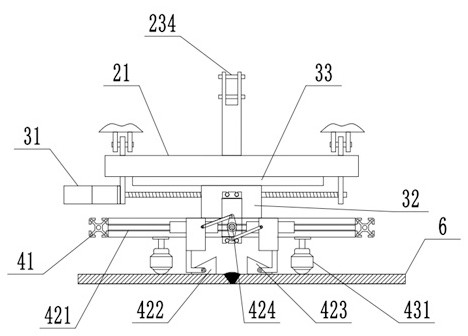

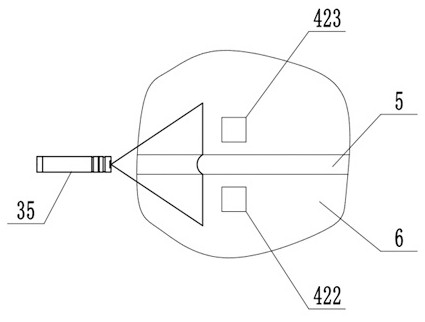

[0047] First, combine the Figure 1~3 The tower weld seam inspection robot according to the embodiment of the present invention is described, which is used for inspection of tower pipe weld seams, and has a wide range of application scenarios.

[0048] Such as Figure 1~3 As shown, the tower weld seam inspection robot according to the embodiment of the present invention has a wall-climbing robot 1 , an adaptive adjustment module, a compensation module and an inspection module.

[0049] Specifically, such as Figure 1~3 As shown, in this embodiment, the self-adaptive adjustment module is connected to the wall-climbing robot 1 for self-adaptive adjustment of the degree of fit between the inspection module and the tower 6, and the compensation module is connected to the self-adaptive ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com