A welding process in electronic detonator chip assembly

An electronic detonator and welding process technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, inconvenient workpiece fixing, and low workpiece protection, so as to improve welding efficiency, facilitate fixing, and ensure Check the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

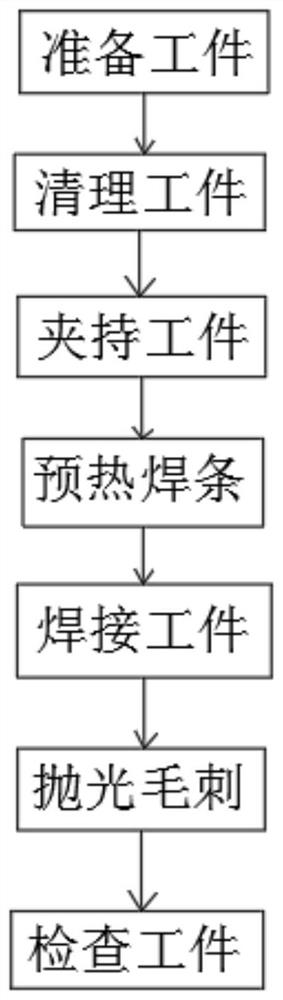

[0031] see figure 1 , a welding process in electronic detonator chip assembly, including preparing workpieces—cleaning workpieces—clamping workpieces—preheating electrodes—welding workpieces—polishing burrs—checking workpieces, and the specific steps are as follows:

[0032] (1) Prepare the workpiece: take out the electronic detonator components and electronic detonator chips that need to be welded, and place them on the workbench for standby;

[0033] (2) Clean up the workpiece: place the electronic detonator assembly and the electronic detonator chip placed on the workbench selected in step (1) on the hand, and check the sundries at the welding position of the electronic detonator assembly and the electronic detonator chip or dust cleaning;

[0034] (3) Clamp the workpiece: move the electronic detonator assembly and the electronic detonator chip that have been cleaned in step (2) to the lower end of the clamping device placed on the workbench, and hold the electronic detona...

Embodiment 2

[0044] A welding process in the assembly of electronic detonator chips, including preparing workpieces—cleaning workpieces—clamping workpieces—preheating electrodes—welding workpieces—polishing burrs—checking workpieces, and the specific steps are as follows:

[0045] (1) Prepare the workpiece: take out the electronic detonator components and electronic detonator chips that need to be welded, and place them on the workbench for standby;

[0046](2) Clean up the workpiece: place the electronic detonator assembly and the electronic detonator chip placed on the workbench selected in step (1) on the hand, and check the sundries at the welding position of the electronic detonator assembly and the electronic detonator chip or dust cleaning;

[0047] (3) Clamp the workpiece: move the electronic detonator assembly and the electronic detonator chip that have been cleaned in step (2) to the lower end of the clamping device placed on the workbench, and hold the electronic detonator assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com