Automatic feeding device of plywood hot press

A technology of automatic feeding and hot pressing, which is used in the joining of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problem of difficult to control the sliding speed, and achieve the effect of convenient control and reduction of transportation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

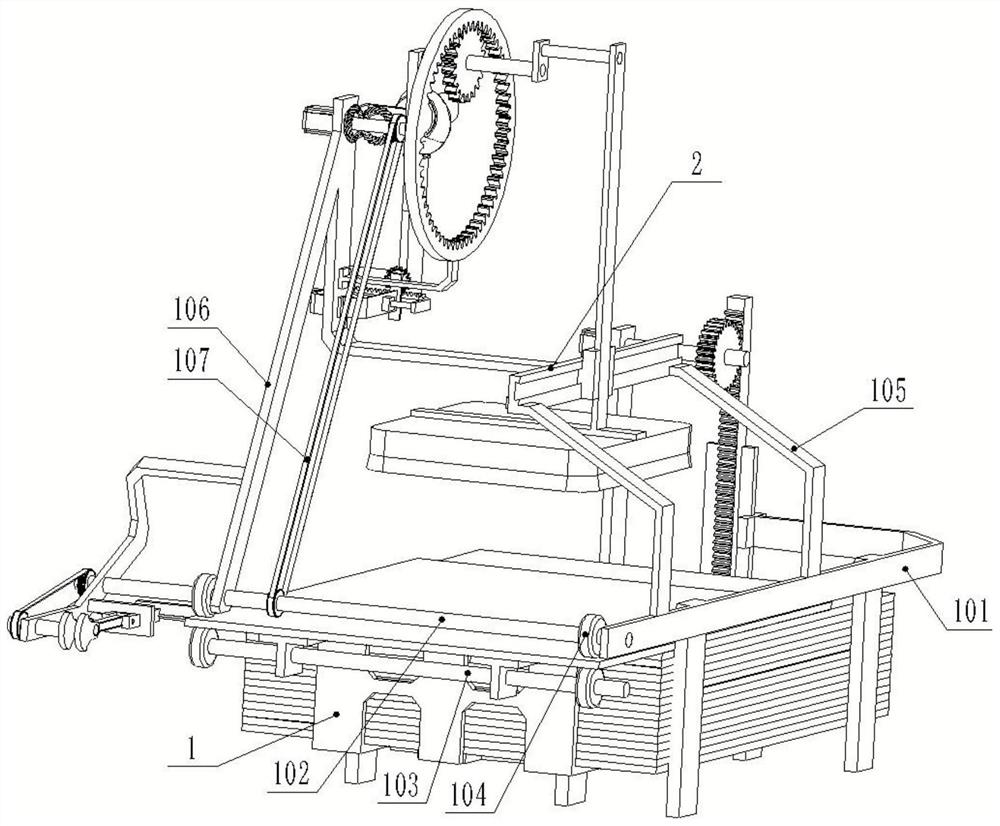

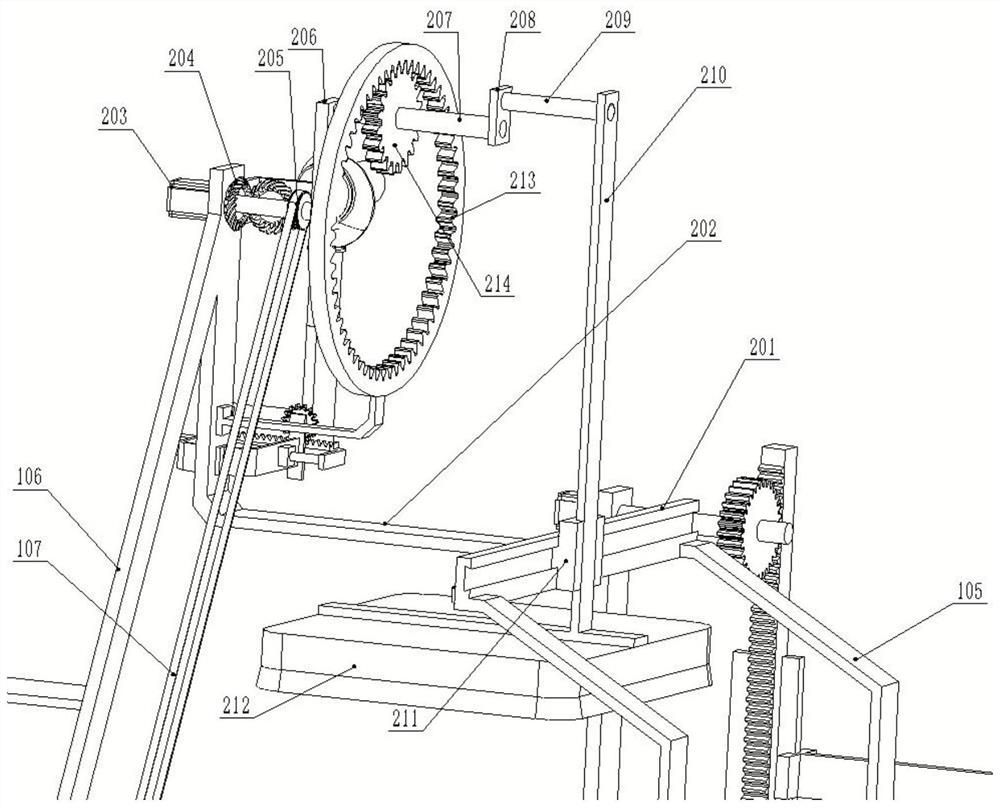

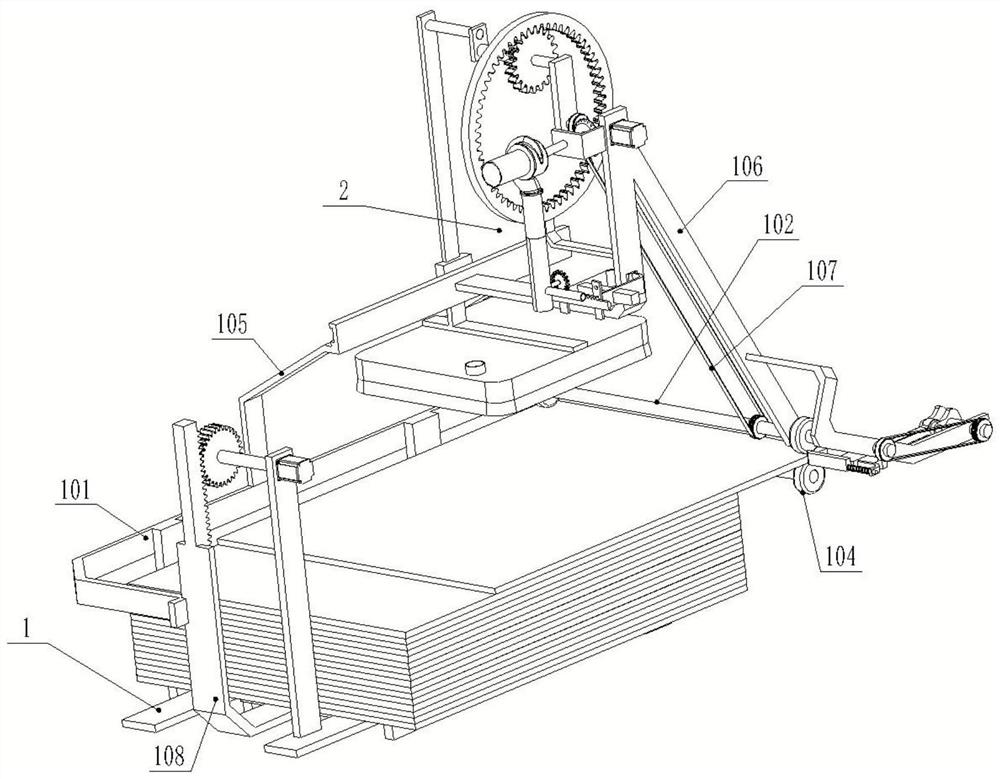

[0027] like Figure 1-12 , an automatic feeding device for a plywood hot press, comprising a material table 1, the material table 1 is provided with a side baffle 101, and an upper horizontal shaft 102 is provided for horizontal rotation on the side baffle 101, and a lower shaft 102 is provided for rotating on the material table 1. The horizontal shaft 103, the lower horizontal shaft 103 is located directly below the upper horizontal shaft 102, and the friction wheel 104 is provided at the corresponding position on the upper horizontal shaft 102 and the lower horizontal shaft 103; a bending support 105 is also fixed on the side baffle 101, and the bending support 105 is fixed with an adsorption mobile device 2; the adsorption mobile device 2 is rotationally connected with the upper horizontal shaft 102 through an oblique support 106, which is used to stabilize the adsorption mobile device 2, and the adsorption mobile device 2 is also connected with the upper horizontal shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com