Turntable mechanism applied to small-angle rotating seat of automobile

A turntable mechanism and small-angle technology, applied in movable seats and other directions, can solve the problems of reducing the robustness and reliability of the rotating function, high manufacturing difficulty, and high cost, and achieve more controllable precision, stable sliding effect, The effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

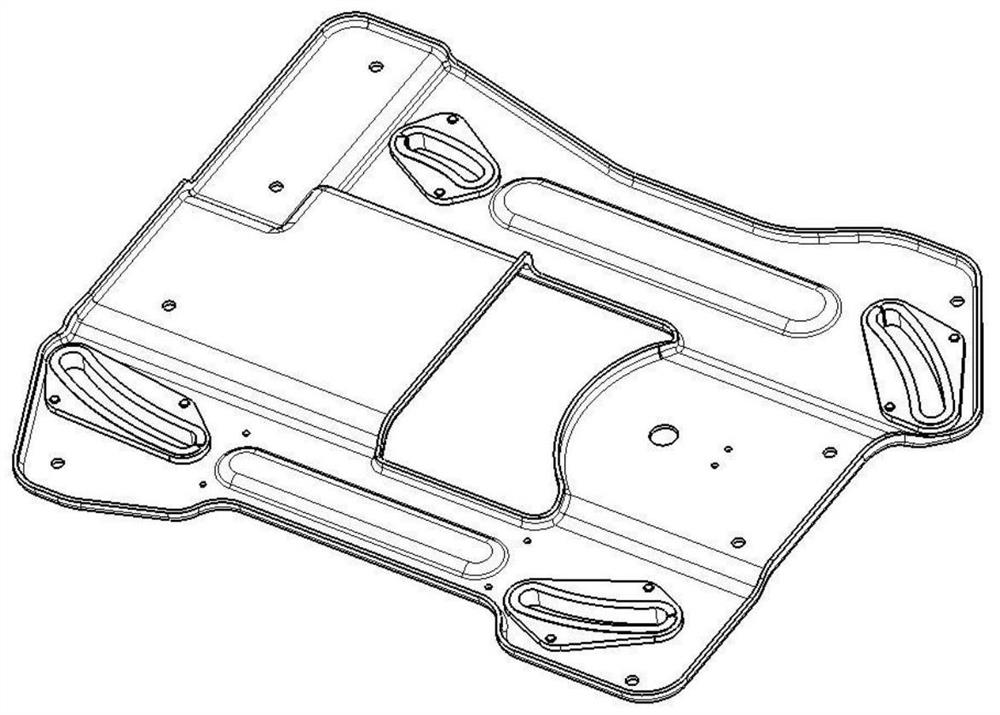

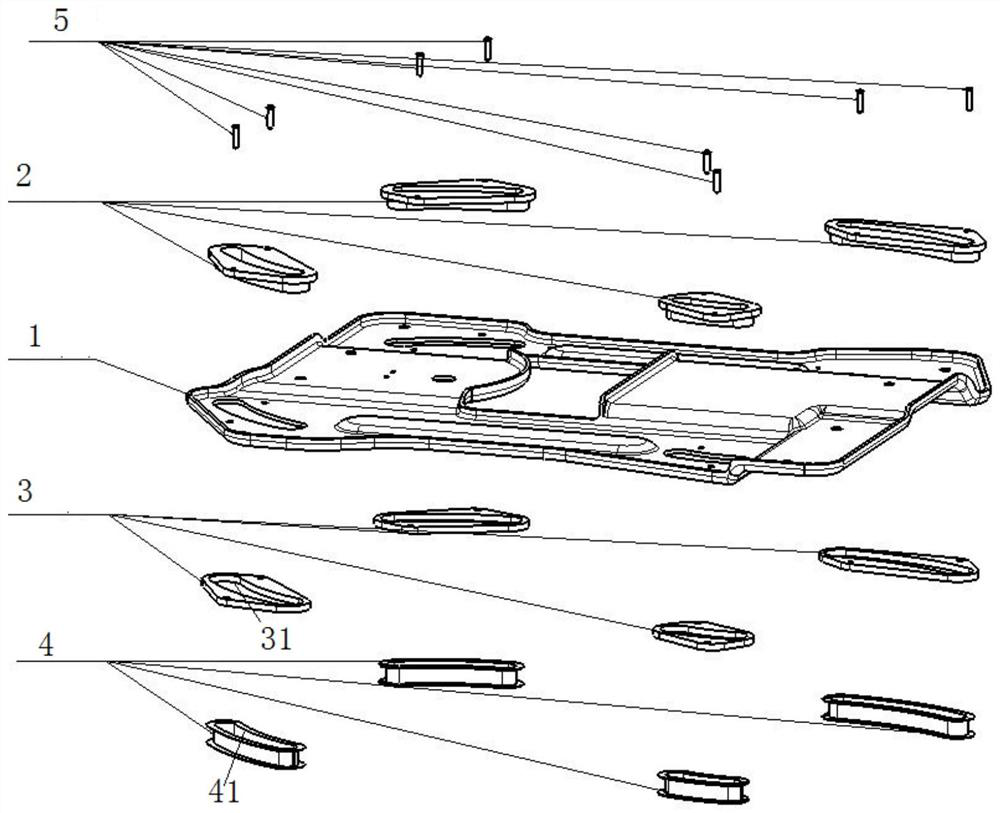

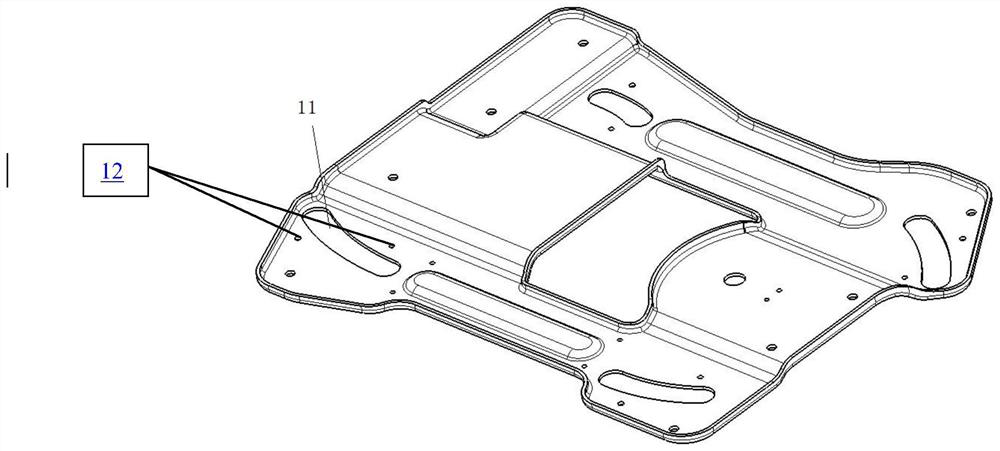

[0027] Such as figure 1 , figure 2 and image 3 As shown, a turntable mechanism applied to small-angle rotating seats for vehicles includes a turntable body 1, a T-shaped reinforcement washer 2, a reinforcement washer buckle cover 3, a self-lubricating sleeve 4 and a positioning pin 5, wherein the four corners of the turntable body 1 There are two locating pins 5 welded on the T-shaped reinforced washer 2, the locating pin rod passes through the locating pin hole 12 of the turntable, the T-shaped reinforcing washer 2 passes through the chute 11 on the curved surface of the turntable, and cooperates with On the turntable body 1, the top of the matching curved surface groove 21 in the middle of the T-shaped reinforcement washer 2 fits the inner wall of the turntable curved surface chute 11, and the reinforcement washer buckle cover 3 is fastened on the T-shaped reinforcement washer 2 at the bottom of the turntable body 1 , and make the outer wall of the matching curved surfac...

Embodiment 2

[0037] A turntable mechanism applied to small-angle rotating seats for vehicles. There is a rectangular hollowed-out area in the middle of the turntable body 1, that is, a weight-reducing hole, which can realize weight reduction of the turntable body 1 and can be used for the arrangement and installation of wiring harnesses. leave space;

[0038] The edges of the inner and outer contours of the turntable body 1 are provided with flanging of more than 3mm, and the reinforcement ribs are reasonably designed to ensure the structural strength;

[0039] The four corners of the turntable body 1 are arranged with four turntable curved surface chutes 11 required for the rotation of the turntable body 1, and the pin shafts matched with the turntable body 1 slide in the turntable curved surface chute 11 to realize the rotation function of the turntable body 1;

[0040] The four corners of the turntable body 1 and the turntable curved surface chute 11 avoid the position, and it is necess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com