Prefabricated assembly type floor and manufacturing method

A prefabricated assembly, ground technology, applied in the direction of floors, local raised floors, buildings, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

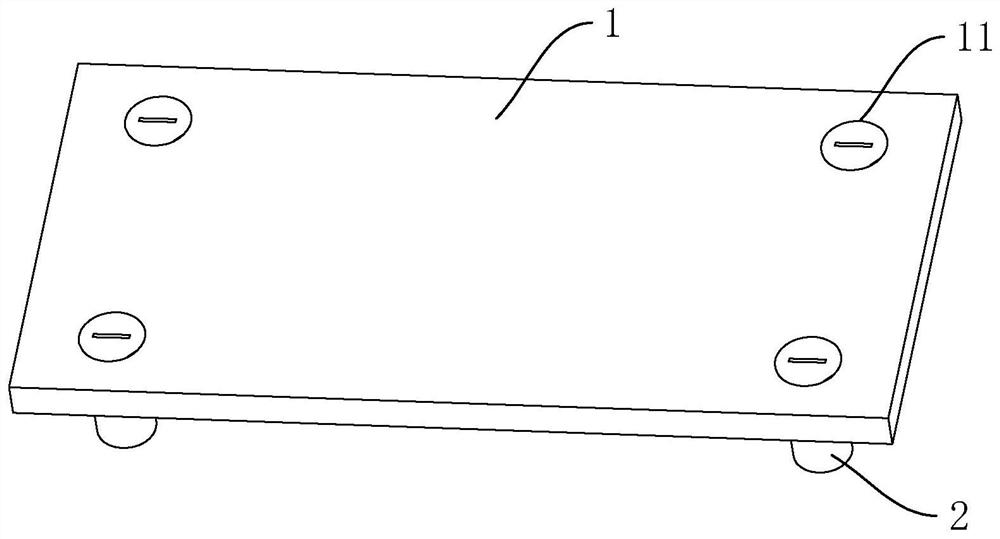

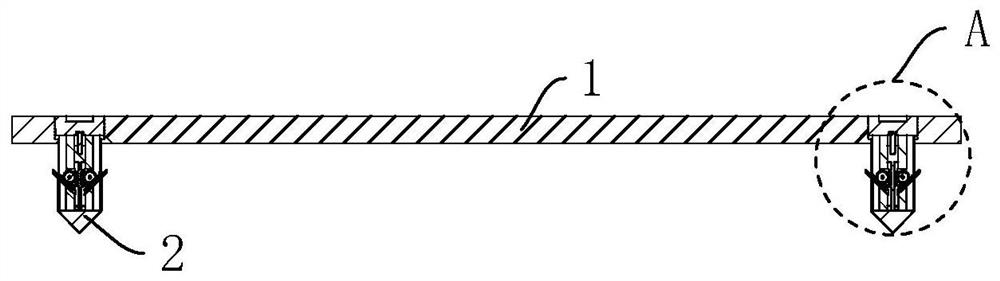

[0040] The embodiment of the present application discloses a prefabricated floor. refer to figure 1 , the prefabricated floor includes a floor panel 1 and a ground post 2 arranged at the bottom of the floor panel 1 .

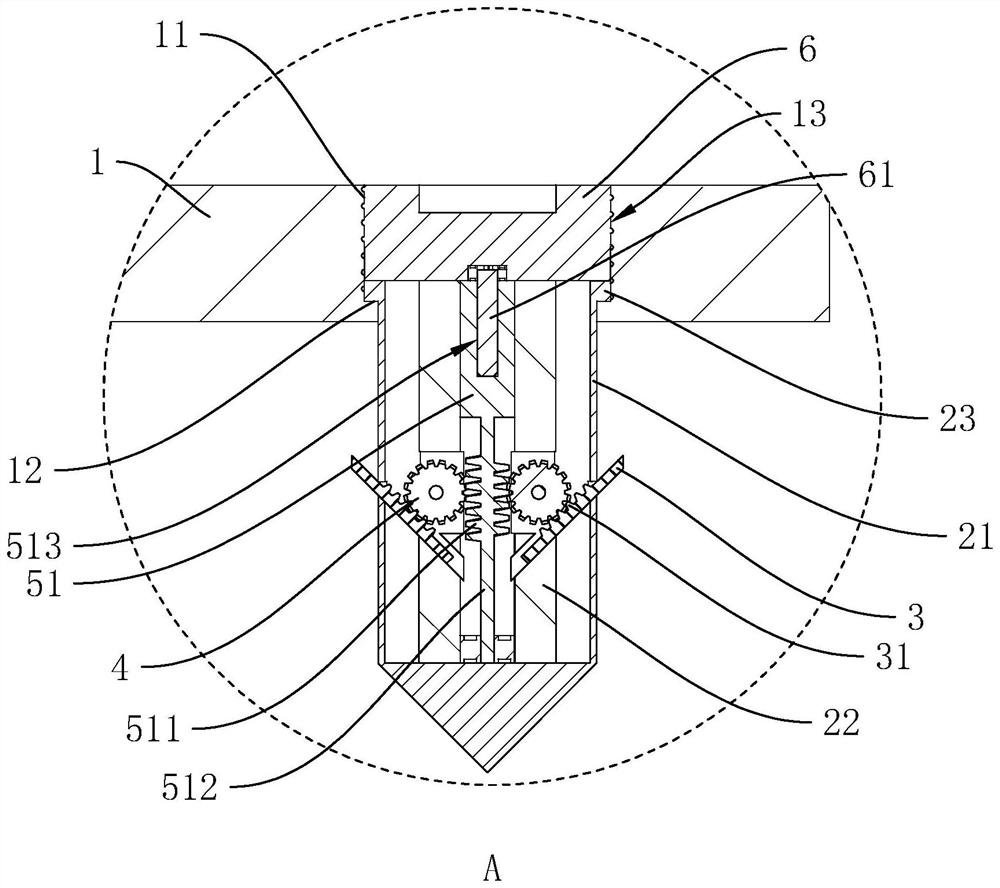

[0041] refer to figure 2 with image 3 wherein the ground panel 1 is provided with a plurality of installation holes 11 for the grip post 2 to pass through at intervals, and the end of the installation hole 11 close to the bottom of the floor panel 1 is inwardly reduced in diameter and a stepped surface 12 is formed in the installation hole 11. The diameter of the top of the ground post 2 expands outward to form an enlarged diameter portion 23 that overlaps the stepped surface 12 , and the enlarged diameter portion 23 abuts against the stepped surface 12 to realize the connection between the ground post 2 and the ground panel 1 . At this time, there is an install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com