Electric valve

An electric valve, valve core technology, applied in valve details, valve device, valve shell structure and other directions, can solve problems such as fluid noise, and achieve the effect of reducing fluid noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the application is further described:

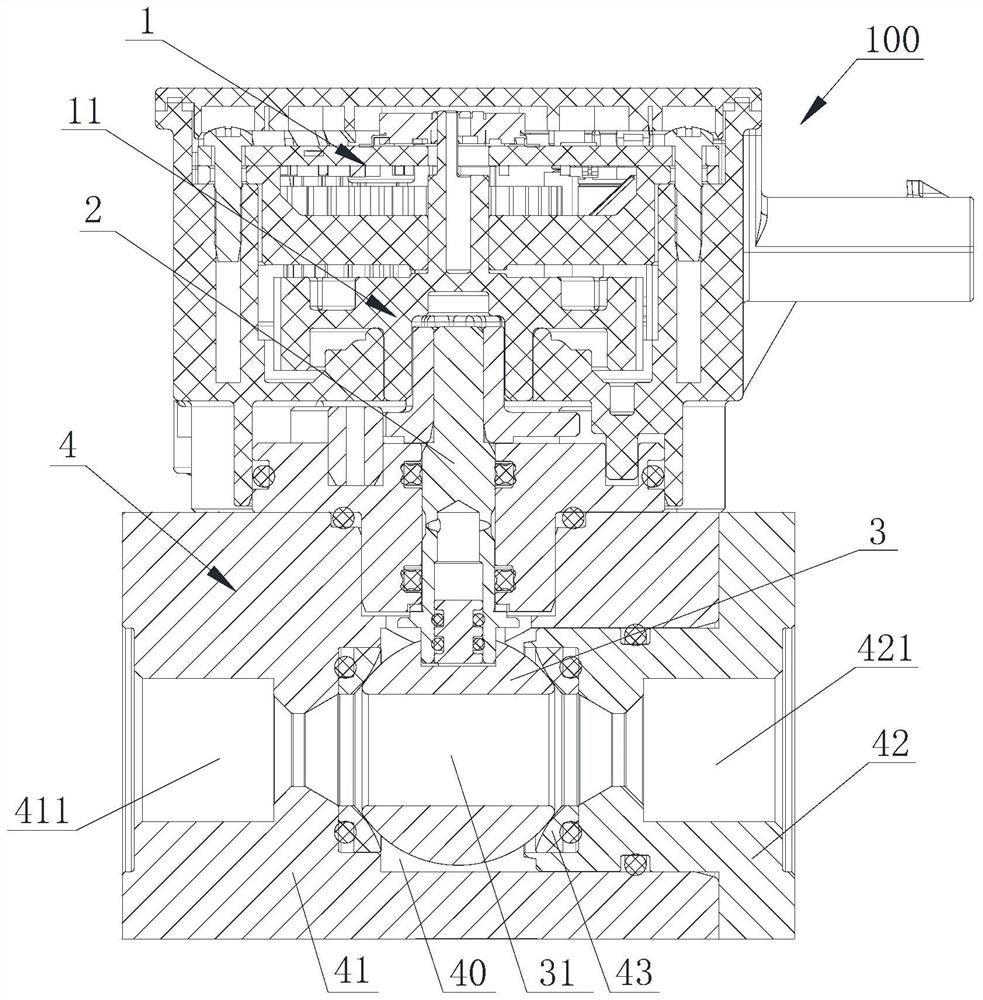

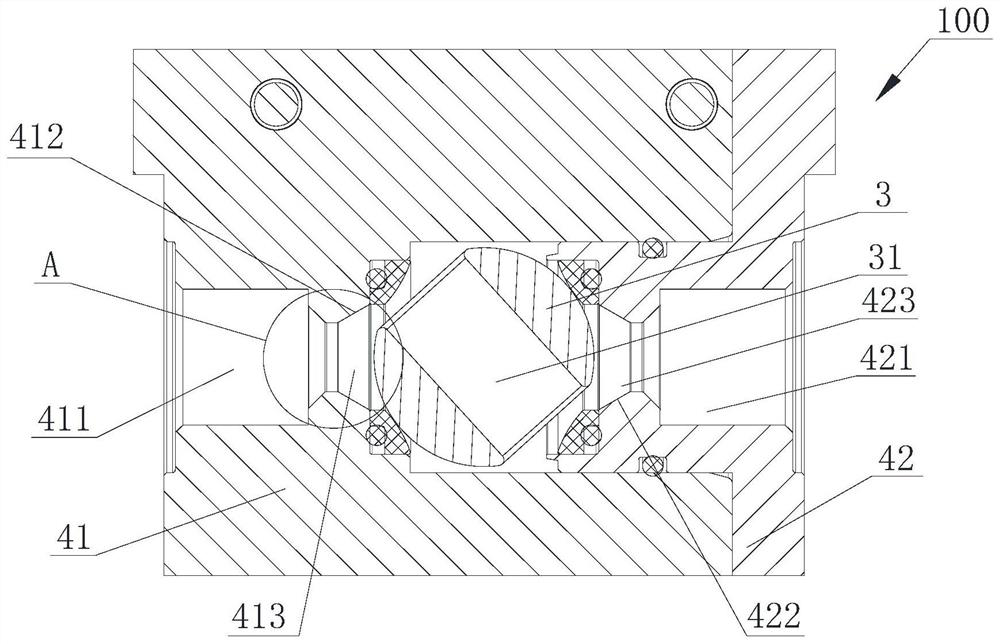

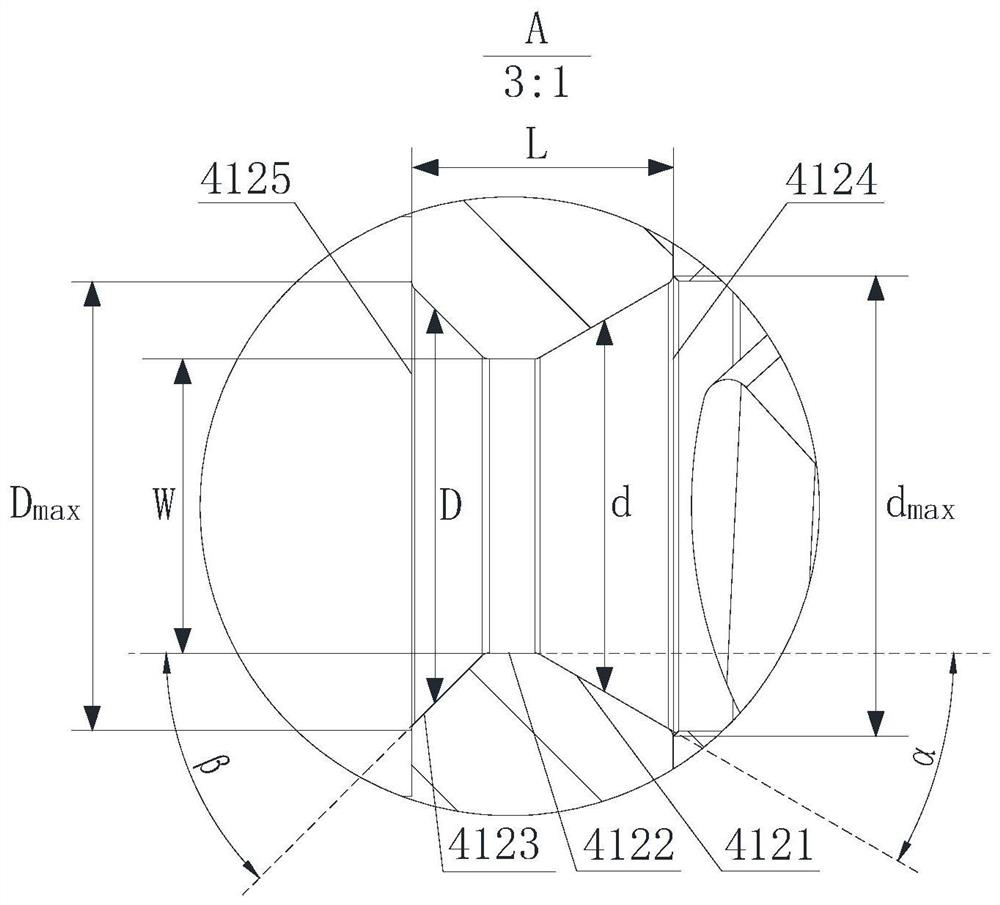

[0016] see figure 1 , the electric valve can be applied to the vehicle thermal management system, the vehicle thermal management system includes the new energy vehicle thermal management system, the electric valve 100 includes the control part 1, the valve stem 2, the valve core 3 and the valve body assembly 4, the valve core 3 is located in the valve body The valve body cavity 40 formed by the assembly 4, one end of the valve stem 2 is in transmission connection with the control part 1, and the other end of the valve stem 2 is in transmission connection with the valve core 3, the control part 1 outputs rotational torque to the valve stem 2, and the valve stem 2 drives the valve core 3 sports. In this embodiment, the valve core 2 is spherical, and the control part 1 also includes a transmission part 11, which can be a gear reduction mechanism. At least part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com