Semi-closed piston refrigeration compressor

A refrigeration compressor, piston type technology, applied in piston pumps, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of reduced work efficiency and energy efficiency, reduced wear resistance of compressors, and increased sliding friction temperature. Improve work efficiency and energy efficiency, improve wear resistance and balance, reduce fluid noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

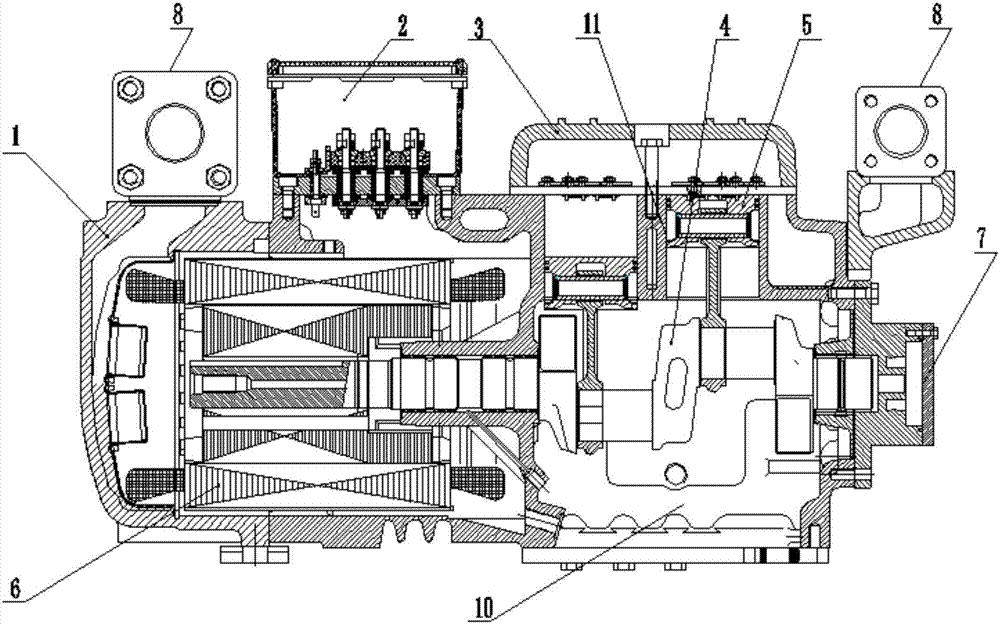

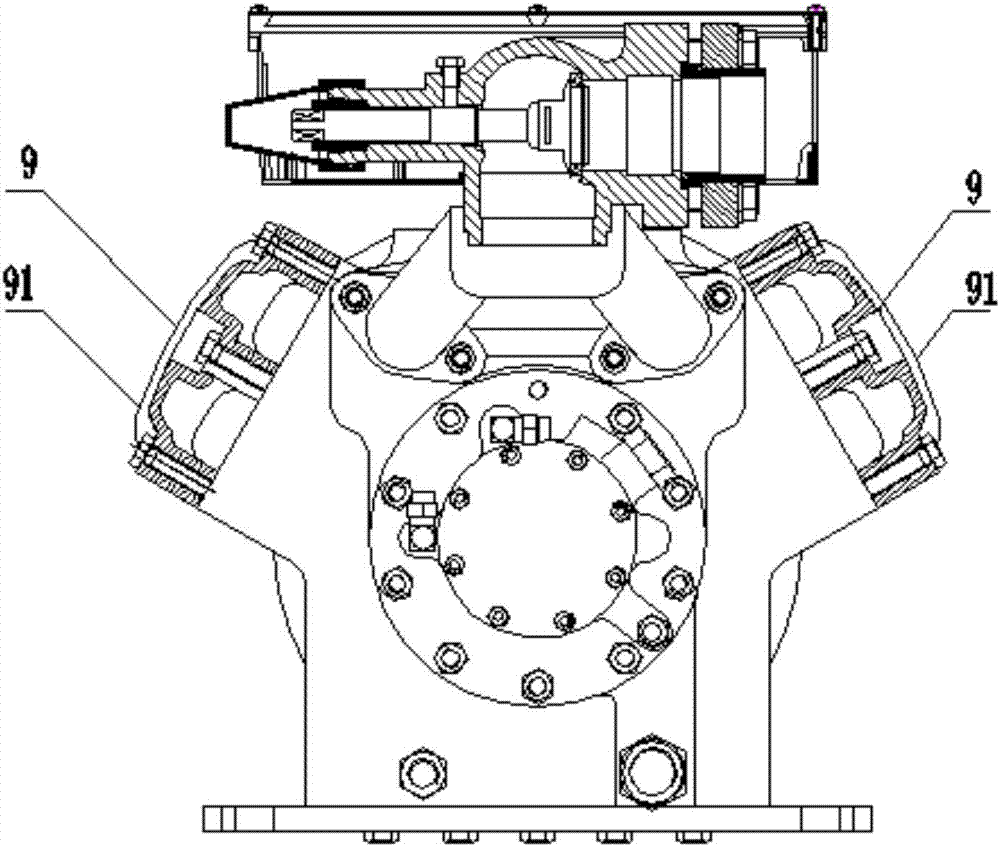

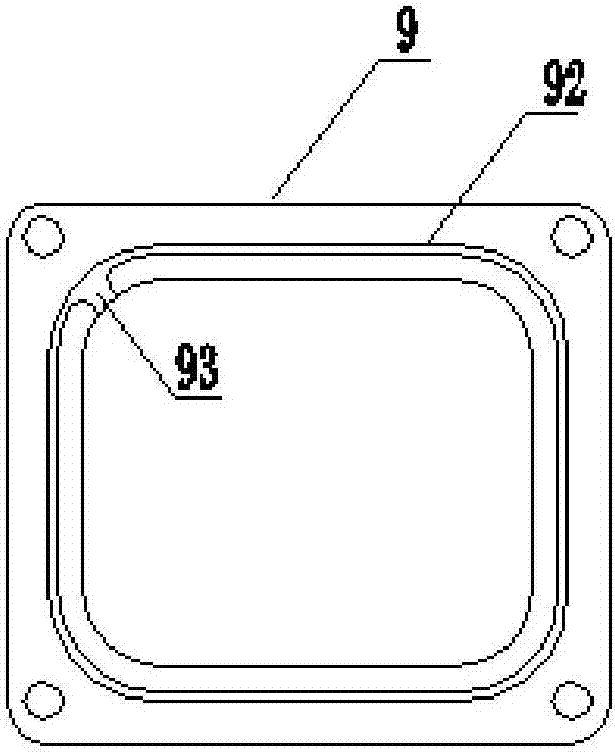

[0015] Such as Figure 1 ~ Figure 4 As shown, the semi-hermetic piston refrigeration compressor includes casing 1, terminal board 2, valve plate 3, crankshaft 4, piston connecting rod assembly 5, motor 6, normal pressure intake valve 7, high pressure exhaust valve 8, cylinder end Cover 9, compressor 10, cylinder block 11, the rotating shaft of the motor 6 is connected to the crankshaft 4, after the compressor 10 is connected to the right end of the motor 6, the crankshaft 4 is correspondingly located in the compressor 10, and the eccentricity of the crankshaft 4 The shaft is connected to the piston connecting rod assembly 5, and the piston in the piston connecting rod assembly 5 is loaded into the cylinder body 11 whose inner wall is evenly distributed with laser texture 1101. The upper end of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com