Motor assembly, fan and range hood

A technology for motor components and range hoods, which is applied in the field of kitchen utensils and can solve problems such as poor sealing, affecting the normal operation of the motor, and failure to start the range hood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

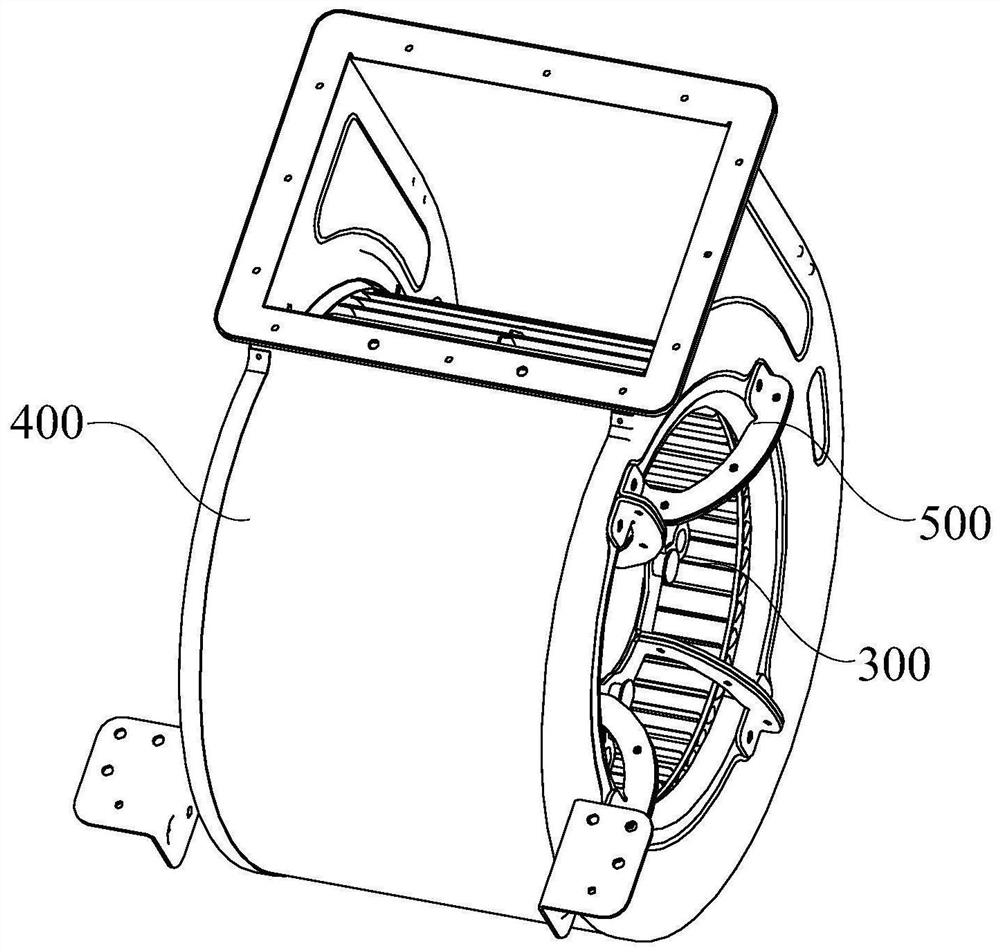

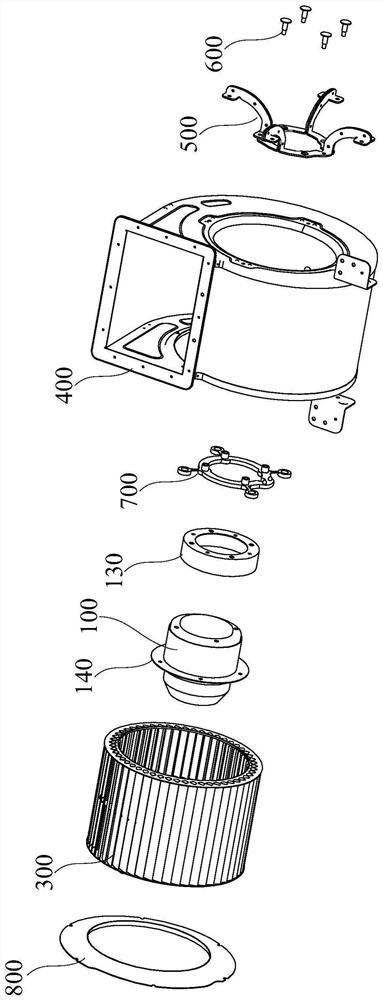

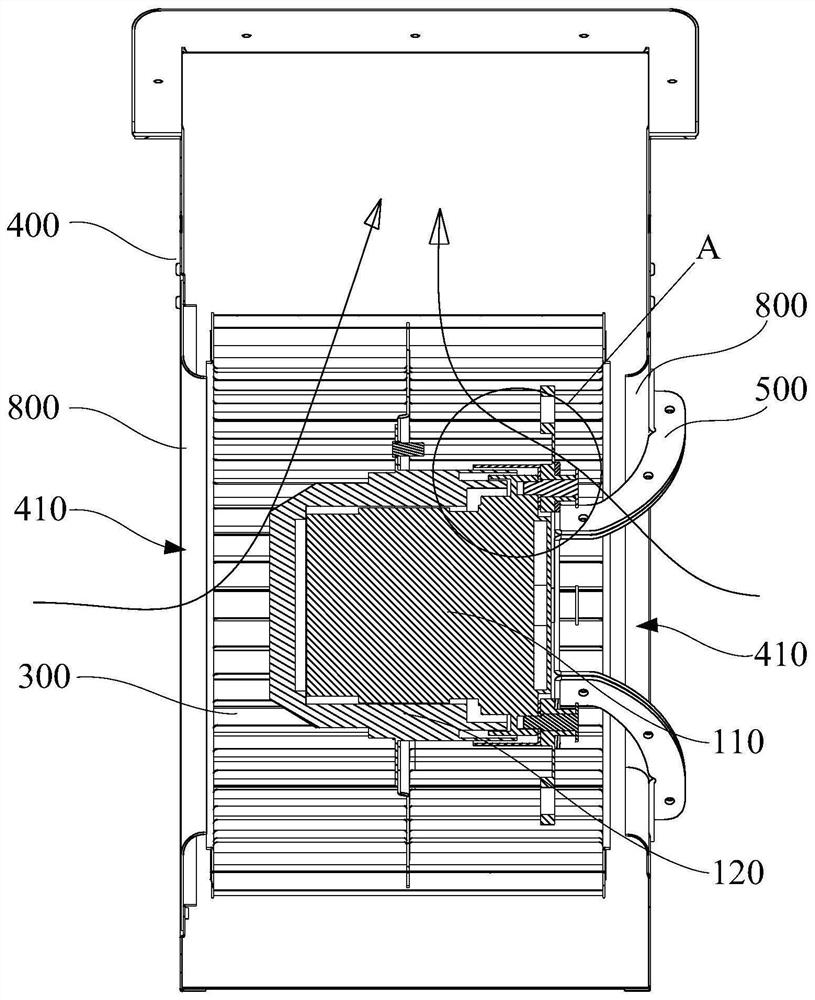

[0051] A motor assembly 100 for a fan, comprising: a stator 110 , a rotor 120 and an oil retainer 130 . Wherein, at least a part of the stator 110 is disposed inside the rotor 120 . The oil deflector 130 includes a mounting portion 131 and a first shielding portion 132 connected to the mounting portion 131, the mounting portion 131 is connected to the first end of the stator 110, the first shielding portion 132 extends from the mounting portion 131 to the outer surface of the rotor 120, to cover a part of the outer surface of the rotor 120 . There is a gap between the first shielding portion 132 and the rotor 120 .

[0052] The motor assembly 100 proposed in this embodiment includes a stator 110 , a rotor 120 and an oil retainer 130 . The rotor 120 is sleeved on the outside of the stator 110, and the installation portion 131 of the oil deflector 130 is arranged on the first end of the stator 110, so that the first shielding portion 132 of the oil deflector 130 extends to the...

Embodiment 2

[0057] On the basis of the first embodiment above, it is further defined that the end of the rotor 120 close to the installation part 131 is provided with a first groove 121 , and the opening of the first groove 121 faces the installation part 131 . The stator 110 is provided with a second groove 112 , and openings of the first groove 121 and the second groove 112 are oppositely distributed. The side wall of the second groove 112 away from the center line of the rotor 120 protrudes into the first groove 121 , and there is a gap between the groove wall of the first groove 121 and the groove wall of the second groove 112 .

[0058] In this embodiment, the second groove 112 is provided on the stator 110 by setting the first groove 121 with the opening facing the installation portion 131 at one end of the rotor 120 close to the installation portion 131, and the first groove 121 and the second groove 121 are connected to each other. Openings of the groove 112 are opposite to each o...

Embodiment 3

[0065] On the basis of the first embodiment above, it is further defined that the oil deflector 130 further includes a second shielding portion 133 connected to the mounting portion 131 . An end of the rotor 120 close to the installation part 131 is provided with a fourth groove 123 , and an opening of the fourth groove 123 faces the installation part 131 . The second shielding portion 133 protrudes into the fourth groove 123 and leaves a gap with the groove wall of the fourth groove 123 .

[0066]In this embodiment, the oil deflector 130 also has a second shielding portion 133 connected to the mounting portion 131, and the end of the rotor 120 close to the mounting portion 131 is provided with a fourth groove 123 opening toward the mounting portion 131, so that The second shielding portion 133 extends into the fourth groove 123 . After the oil fume enters the gap between the first shielding portion 132 and the outer surface of the rotor 120 , it needs to turn to enter the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com