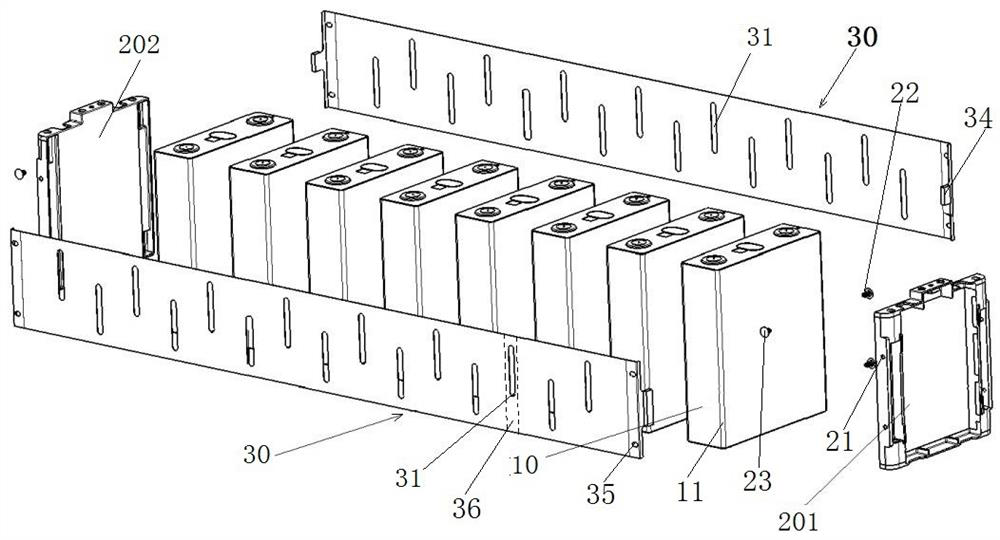

Battery module with heating function and battery box

A battery module and functional technology, which is applied to battery pack components, secondary batteries, circuits, etc., can solve the problems of easy falling off of the heating film and reduce the service life of the battery module, and achieve the effect of improving the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

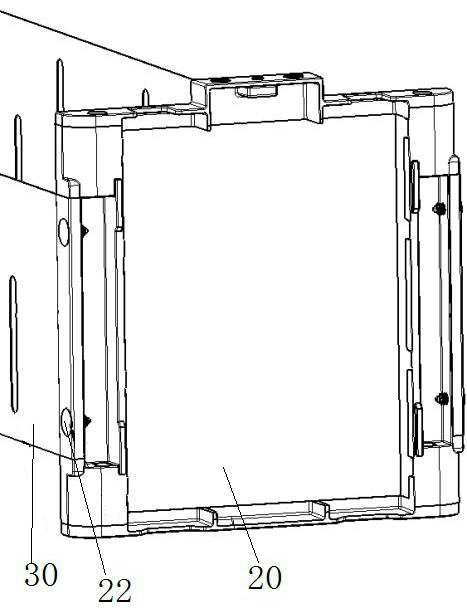

Examples

Embodiment 2

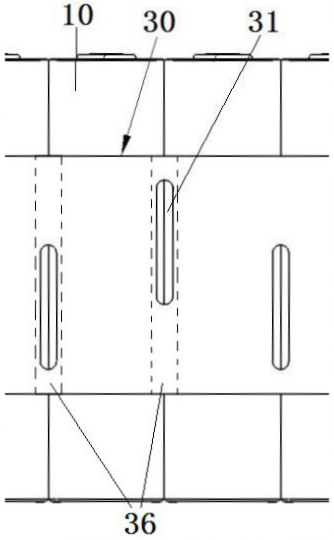

[0083] Specific embodiment 2 of the battery module with heating function in the present invention: the difference from the above specific embodiment is that in this embodiment, the heating film is provided with an unloading seam that replaces the unloading hole in specific embodiment 1, such as Figure 7 As shown, an unloading seam 32 is processed on the heating film 30 by mechanical punching, and the unloading seam 32 extends along a direction perpendicular to the cell stack. When stretching with variable expansion force, the opening at the unloading slot 32 is enlarged, so that the heating film 30 has a greater degree of deformation. At the same time, two ends of the unloading seam 32 are punched with circular holes, and the edges of the circular holes transition smoothly, which can prevent the heating film from being torn here. It should be noted that the only shape of the unloading seam in this embodiment is different from that of the unloading hole in Embodiment 1, and th...

specific Embodiment 3

[0084] Specific embodiment 3 of the battery module with heating function in the present invention: The structure of the battery module in this embodiment is different from the above specific embodiments only in that: in this embodiment, the movable terminal is connected to the end plate Long holes extending back and forth are also provided.

specific Embodiment 4

[0085] Specific embodiment 4 of the battery module with heating function in the present invention: The structure of the battery module in this embodiment is different from the above-mentioned specific embodiments only in that the connecting piece is a fixing bolt, and the fixing bolt is screwed on the end On the board, the movement of the end of the heating film against the cell is restricted by the bolt head of the fixing bolt. In other embodiments, the connecting piece may also be fixed on a pin on the end plate, and a blocking cap is provided at one end of the pin to limit separation from the pin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com