Continuous protein renaturation device based on enzyme engineering

A protein and continuous technology, applied in the field of protease engineering, can solve the problems of uneven stirring, long time consumption, manual calculation time, etc., and achieve the effect of facilitating protein renaturation and avoiding protein precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

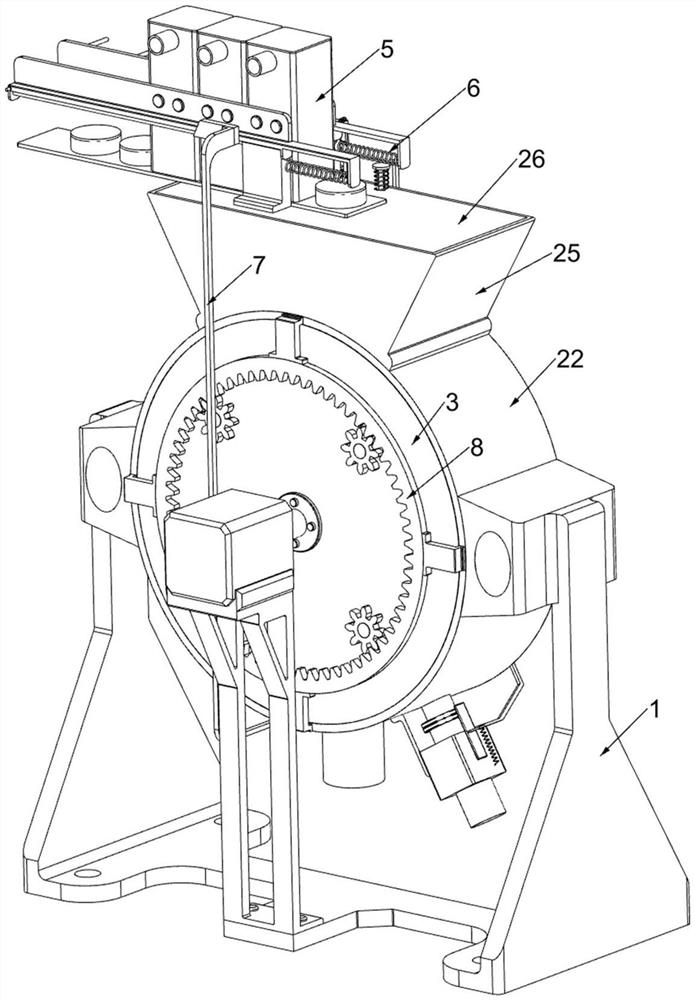

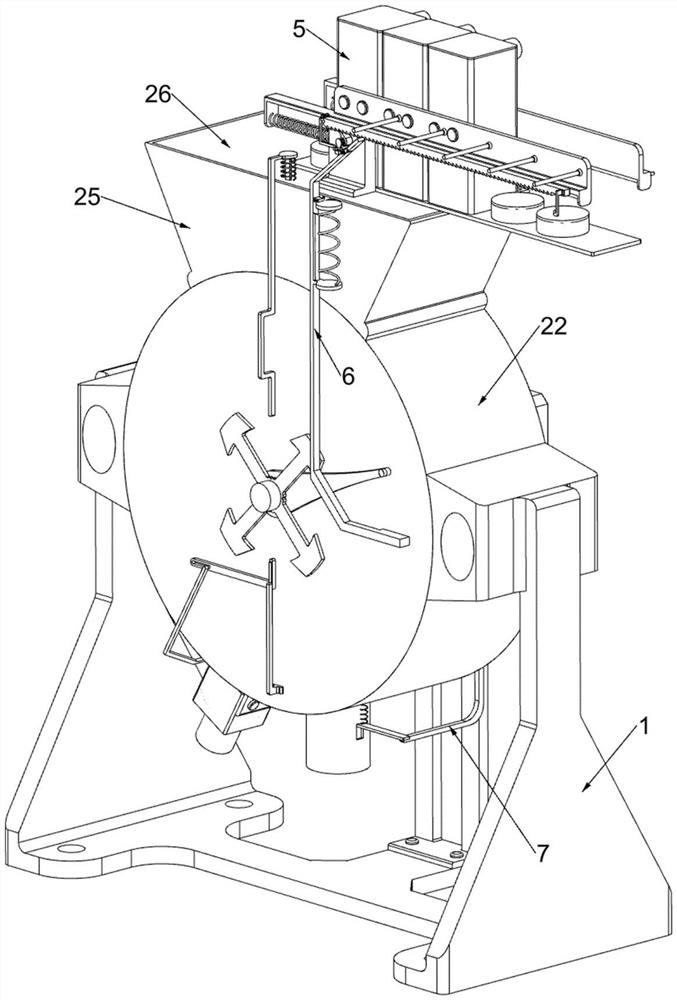

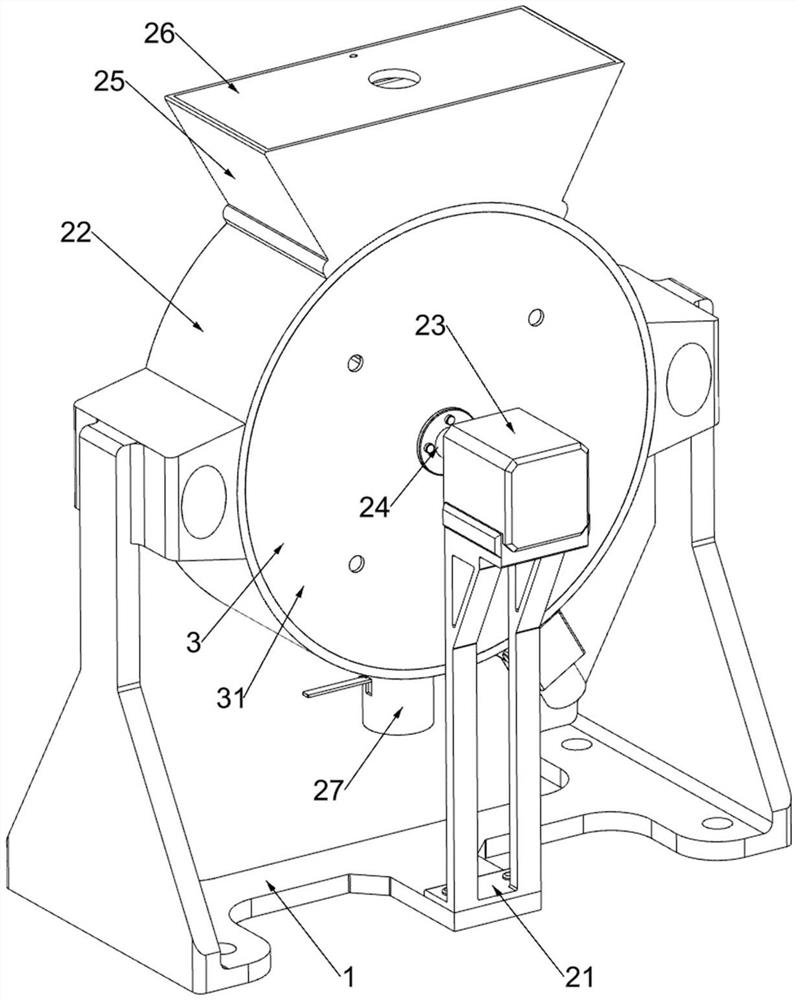

[0053] A continuous protein renaturation device based on enzyme engineering, such as Figure 1-10 As shown, it includes a first support frame 1, a second support frame 21, a reaction frame 22, a motor 23, a turret 24, a first support frame 25, a fixed support plate 26, a discharge pipe 27, a sliding frame 28, and an opening frame 29. The first spring 210, the agitating assembly 3 and the separating assembly 4, the first support frame 1 is connected with the second support frame 21 by means of fasteners, the first support frame 1 is fixedly installed with the reaction frame 22, the second The motor 23 for driving is fixedly installed on the top of the two support frame 21, and one end of the output shaft of the motor 23 is welded with a turret 24. A support frame 25 is provided with a fixed support plate 26, and a discharge pipe 27 is fixedly connected to the bottom of the reaction frame 22. The discharge pipe 27 is used to discharge the solution. The discharge pipe 27 is slida...

Embodiment 2

[0058] On the basis of Example 1, such as Figure 10-14 As shown, an injection assembly 5 is also included. The injection assembly 5 is fixedly installed on the top surface of the fixed support plate 26. The injection assembly 5 is used to add protein dialysate towards the reaction frame 22. The injection assembly 5 includes an L-shaped support plate 51, a sliding Support frame 52, liquid storage frame 53, input pipe 531, first hole frame 532, second hole frame 533, third hole frame 534, fourth support frame 54, first plug frame 55, second plug frame 551, the third blocking frame 552, the third spring 56, the protective folding cover 57, the buoyancy retaining frame 58, the barrier plate 581, the special-shaped pushing frame 59 and the fourth spring 510, and the top surface of the fixed support plate 26 is fixedly equipped with two L-shaped supports Plate 51, a sliding support frame 52 is slidably connected to the L-shaped support plate 51, and three liquid storage frames 53 a...

Embodiment 3

[0063] On the basis of Example 2, such as Figure 14-17 As shown, it also includes a switching assembly 6, the first support frame 25 is provided with a switching assembly 6, the switching assembly 6 is used to switch the concentration of the added protein dialysate, the switching assembly 6 includes a rocker 61 with a column, a fifth spring 6101, the fifth support frame 62, guide frame 63, swing plate 631, first torsion spring 632, sixth spring 64, ratchet bar 65, toggle lever 66, support slider 67, sliding frame 68, pawl 69, The second torsion spring 610, the first resetting frame 611, the seventh spring 612 and the second resetting frame 613, are fixedly connected with the rocker 61 with the clamping post on the turret 24, and are connected between the L-shaped support plate 51 and the sliding support frame 52. There is a fifth spring 6101, a fifth support frame 62 is fixedly connected to the first support frame 25, a guide frame 63 is slidably connected to the fifth suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com