Yoghurt prepared liquor and preparation method thereof

A technology for preparing wine and yogurt, applied in the preparation of alcoholic beverages, etc., can solve problems affecting appearance and consumer experience, improve product appearance and consumer experience, avoid protein precipitation, and ensure sweet and sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A kind of yoghurt concoction made from the following raw materials: according to the mass concentration, it includes 10-15% fructose syrup, 0.01-0.05% sodium carboxymethylcellulose, 0.0005-0.002% pectin, and 0.08-0.12% lactic acid bacteria beverage %, citric acid 0.03-0.07%, malic acid 0.1-0.2%, sodium citrate 0.05-0.1%, lactic acid 0.01-0.02%, yogurt essence 0.06-0.12%, sweet orange juice 0.01-0.03%, grapefruit juice 0.01-0.03 %, vodka 3.0-3.3%, emulsified essence 0.03-0.09%, purified water 20-30%, and the balance is deoxygenated water.

Embodiment 2

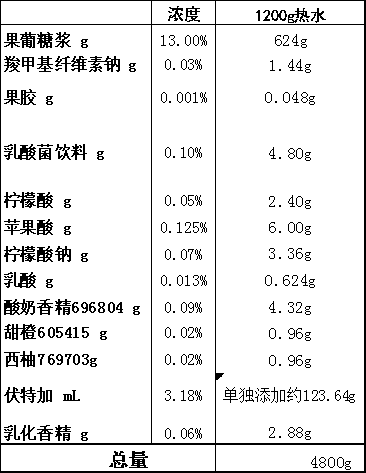

[0014] The yogurt wine is characterized in that, according to the mass concentration, it includes 13% fructose syrup, 0.03% sodium carboxymethylcellulose, 0.001% pectin, 0.1% lactic acid bacteria beverage, 0.05% citric acid, 0.125% malic acid, lemon Sodium acid 0.07%, lactic acid 0.013%, yogurt flavor 0.09%, sweet orange juice 0.02%, grapefruit juice 0.02%, vodka 3.18%, emulsified flavor 0.06%, purified water 25%, the balance is deoxygenated water.

[0015]

[0016] For example, in the actual production process, if a total of 4800g of yogurt wine is produced, the mass concentration of each formula is shown in the following table:

Embodiment 3

[0018] A method for preparing yogurt wine, step 1, heating quantitative pure water to 65±2°C and pouring it into a gelatinization pot, adding quantitative fructose syrup while stirring, and then adding quantitative sodium carboxymethylcellulose and pectin , and then stir evenly, the sodium carboxymethylcellulose and pectin in it flow into a container in turn, use a small amount of pure water above 80°C to stir into a paste, then dilute with hot water, add it to the gelatinization pot and stir for 10 minutes , so that the dissolution is completed; step 2, add quantitative lactic acid bacteria beverage to the gelatinization pot while stirring, and then stir evenly; step 3, add quantitative citric acid, malic acid, sodium citrate, lactic acid to the In the gelatinization pot, stir evenly, add quantitative pure water and then cool it for later use; step 4, add the contents of the gelatinization pot into the mixing tank, and then add quantitative yogurt essence, sweet orange juice, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com