Method for manufacturing tire mold and method for manufacturing tire

A manufacturing method and mold technology, which is applied in the field of tire manufacturing, can solve problems such as the influence of tire appearance, and achieve the effect of excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

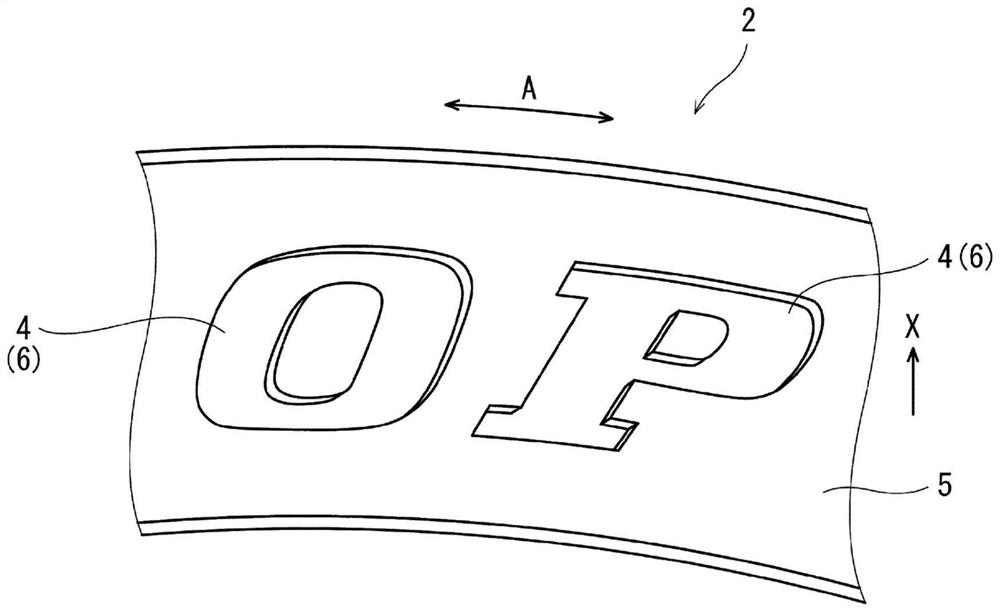

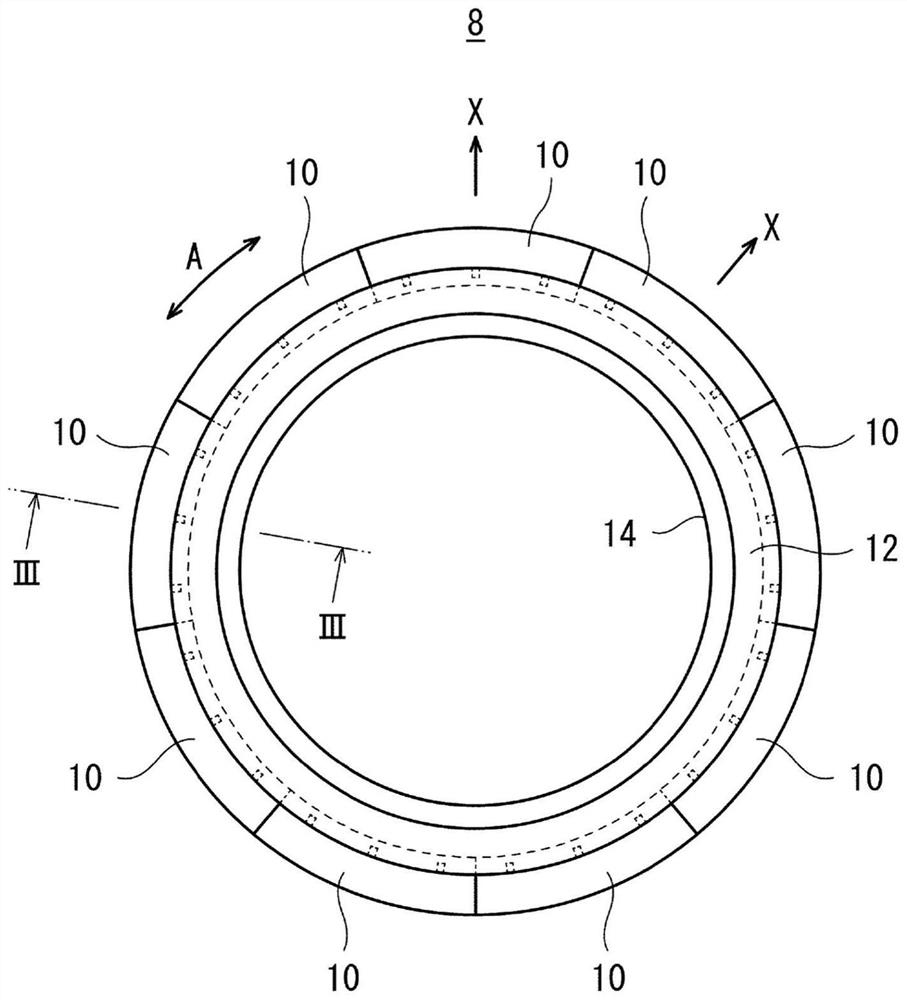

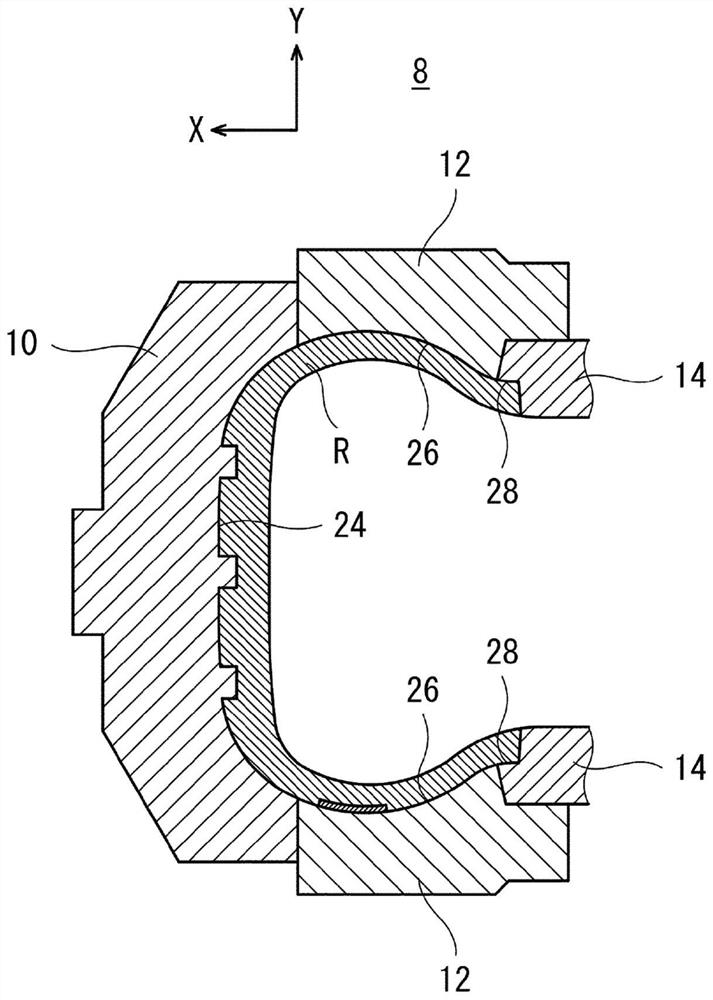

[0060] In the method of (1)-(4) above, formed figure 2 and 3 The cavity face of the side plate shown. The cavity surface of the side plate has a convex portion for forming characters on the tire. In the step (1) above, a base material made of steel is prepared. In the step (2) above, the base cavity surface is formed by lathe processing. In the step (3) above, an iron alloy layer is formed on the base cavity surface by electroplating. The iron content of this iron alloy was 99% by mass. The surface area of the layer of iron alloy is 15% of the surface area of the base cavity face. In the step (4) above, the iron alloy layer is cut by engraving to form protrusions for forming characters on the tire. Thus, the cavity surface is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com