Multifunctional steam turbine inner cylinder

A steam turbine, multi-functional technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of wasted space, large volume, high cost, etc., achieve the effect of reducing support columns, reducing processing time, and saving production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

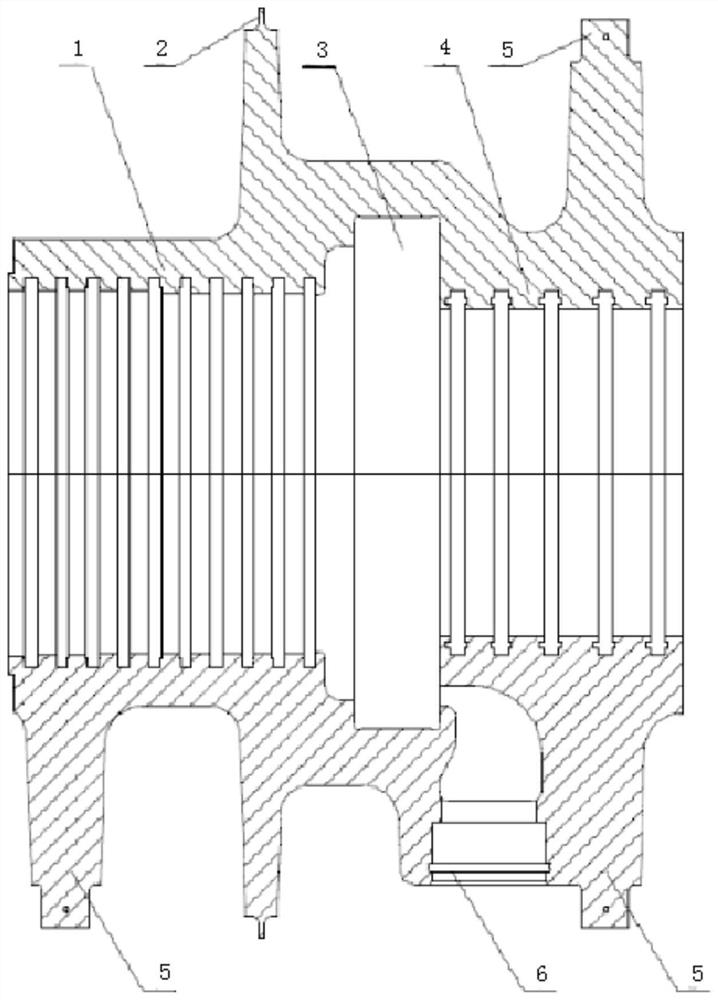

[0021] The present invention provides such figure 1 The multifunctional steam turbine inner cylinder shown, including the inner cylinder main body;

[0022] The main body of the inner cylinder includes a partition cover 1, a steam retaining ring 2, a steam chamber 3 and a steam seal body 4. One end of the partition cover 1 is integrally formed with a steam chamber 3 by casting, and one end of the steam chamber 3 is formed by casting The steam seal body 4 is integrally formed, the surface of the partition cover 1 is integrally formed with a steam barrier ring 2 by casting, the surface of the steam chamber 3 is provided with a steam inlet 6, and the interior of the steam chamber 3 is provided with a cavity for steam circulation chamber, the steam inlet 6 is connected to the inside of the chamber, the port of the steam inlet 6 is set as a columnar structure, the interior of the partition cover 1 and the seal body 4 are provided with cavities, the partition cover 1 and the seal bo...

Embodiment 2

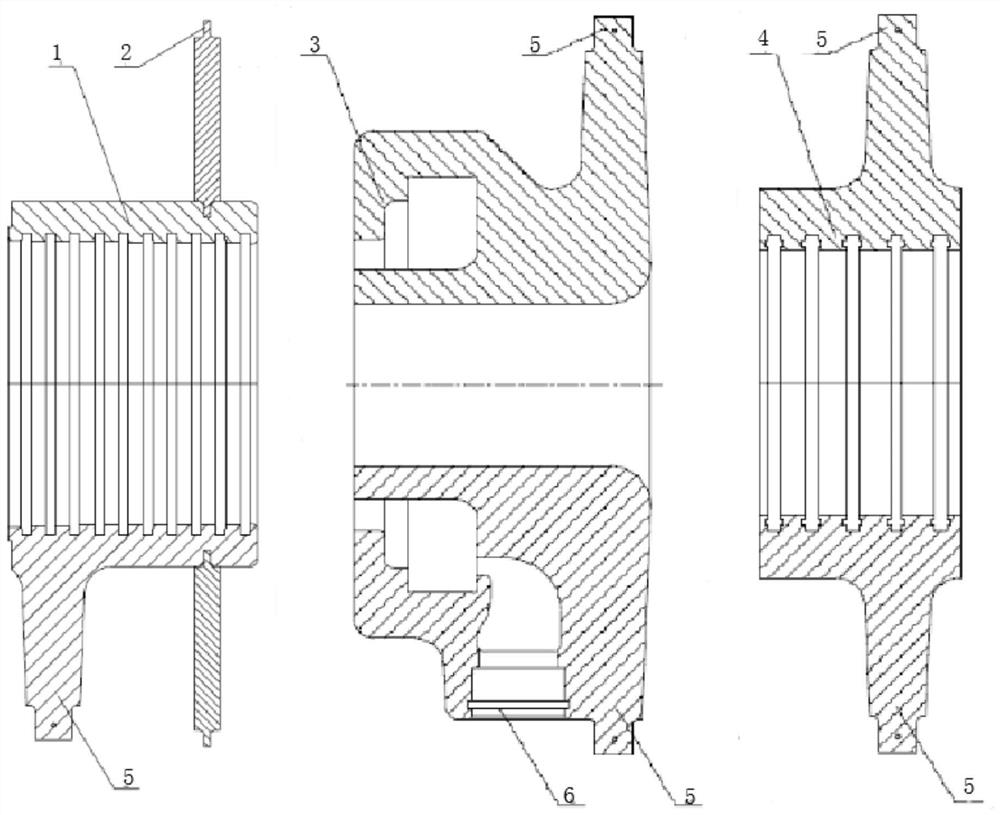

[0028] Multifunctional steam turbine inner cylinder, including inner cylinder main body;

[0029] The main body of the inner cylinder includes a partition cover 1, a steam retaining ring 2, a steam chamber 3 and a steam seal body 4. One end of the partition cover 1 is integrally formed with a steam chamber 3 by casting, and one end of the steam chamber 3 is formed by casting The steam seal body 4 is integrally formed, the surface of the partition cover 1 is integrally formed with a steam barrier ring 2 by casting, the surface of the steam chamber 3 is provided with a steam inlet 6, and the interior of the steam chamber 3 is provided with a cavity for steam circulation chamber, the steam inlet 6 is connected to the inside of the chamber, the port of the steam inlet 6 is set as a columnar structure, the interior of the partition cover 1 and the seal body 4 are provided with cavities, the partition cover 1 and the seal body The surface of 4 is integrally formed with support colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap