Solar intelligent LED lamp shell auxiliary automatic screwing assembly equipment

A technology of LED lamp housing and assembling equipment, applied in the field of solar energy, can solve the problems of inconvenient assembly operation, low efficiency of housing assembly, affecting the efficiency of solar intelligent LED lamp production, etc., and achieve the effect of improving the effect and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

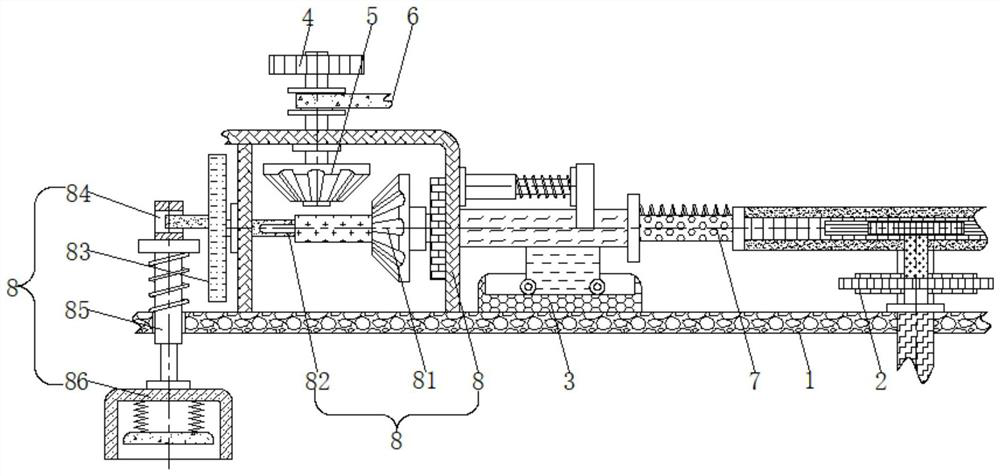

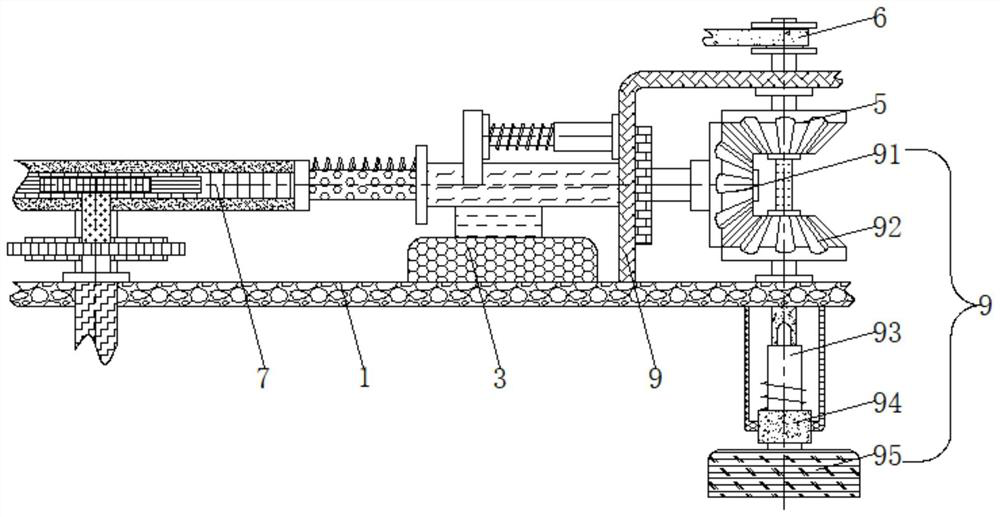

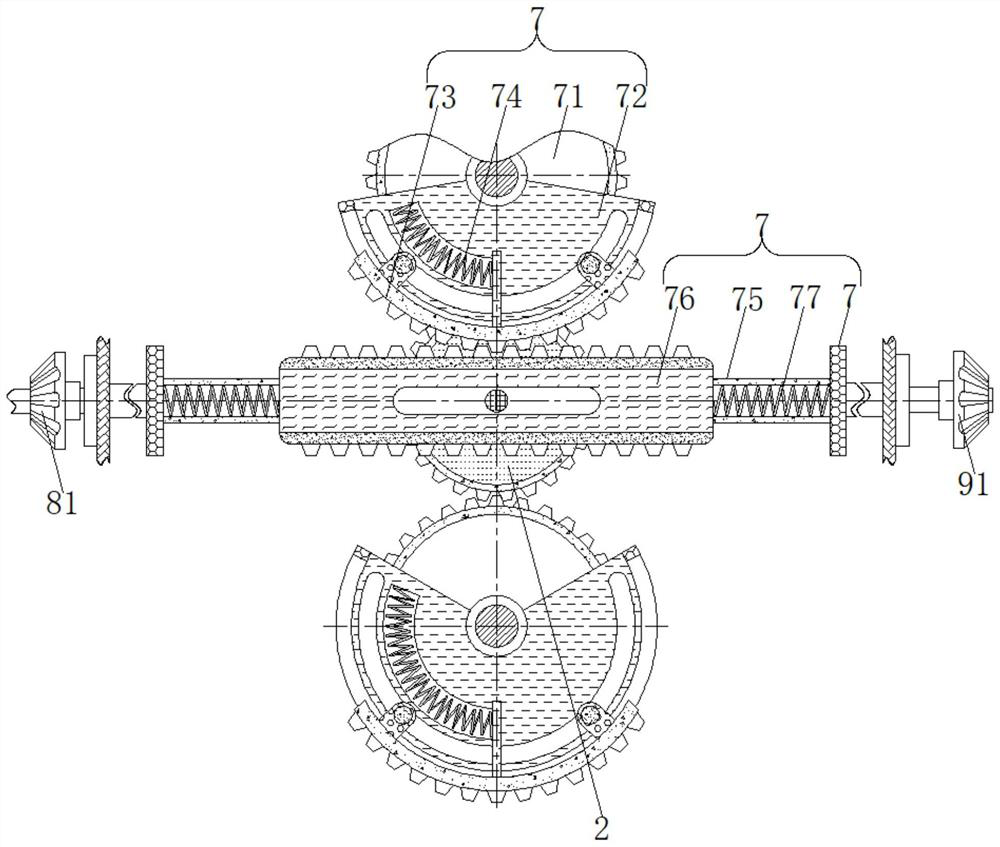

[0025] see Figure 1-3 , a solar intelligent LED lamp shell auxiliary automatic screwing assembly equipment, including a body 1, the inside of the body 1 is provided with a transmission gear 2, which meshes with a toothed disc 71 to drive the toothed disc 71 to rotate, and the interior of the body 1 is provided with a slide rail 3. It is used to move the slide bar 75. The inside of the body 1 is provided with a driving gear 4, which is used to drive the first gear 5 to rotate. The lower part of the driving gear 4 is provided with a first gear 5. There are two first gears 5, which are symmetrical Distributed inside the body 1, the first gear 5 adopts a bevel gear design, meshes with the first gear 81 and the second gear 91, and drives the first gear 81 and the second gear 91 to rotate.

[0026] The surface of the first gear 5 is provided with a transmission belt 6, and the transmission belt 6 is located between the two first gears 5, and is used to drive the other first gear 5 ...

Embodiment 2

[0030] see Figure 1-3 , a solar intelligent LED lamp shell auxiliary automatic screwing assembly equipment, including a body 1, the inside of the body 1 is provided with a transmission gear 2, which meshes with a toothed disc 71 to drive the toothed disc 71 to rotate, and the interior of the body 1 is provided with a slide rail 3. It is used to move the slide bar 75. The inside of the body 1 is provided with a driving gear 4, which is used to drive the first gear 5 to rotate. The lower part of the driving gear 4 is provided with a first gear 5. There are two first gears 5, which are symmetrical Distributed inside the body 1, the first gear 5 adopts a bevel gear design, meshes with the first gear 81 and the second gear 91, and drives the first gear 81 and the second gear 91 to rotate.

[0031] The surface of the first gear 5 is provided with a transmission belt 6, and the transmission belt 6 is located between the two first gears 5, and is used to drive the other first gear 5 ...

Embodiment 3

[0035] see Figure 1-3 , a solar intelligent LED lamp shell auxiliary automatic screwing assembly equipment, including a body 1, the inside of the body 1 is provided with a transmission gear 2, which meshes with a toothed disc 71 to drive the toothed disc 71 to rotate, and the interior of the body 1 is provided with a slide rail 3. It is used to move the slide bar 75. The inside of the body 1 is provided with a driving gear 4, which is used to drive the first gear 5 to rotate. The lower part of the driving gear 4 is provided with a first gear 5. There are two first gears 5, which are symmetrical Distributed inside the body 1, the first gear 5 adopts a bevel gear design, meshes with the first gear 81 and the second gear 91, and drives the first gear 81 and the second gear 91 to rotate.

[0036] The surface of the first gear 5 is provided with a transmission belt 6, and the transmission belt 6 is located between the two first gears 5, and is used to drive the other first gear 5 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap