Method for testing lens module assembling element

A technology for testing lenses and lens modules, which is applied in the direction of testing optical performance, optics, instruments, etc., to achieve the effect of improving efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for testing lens module assembly components provided by the embodiment of the technical solution will be further described in detail below with reference to the accompanying drawings and embodiments.

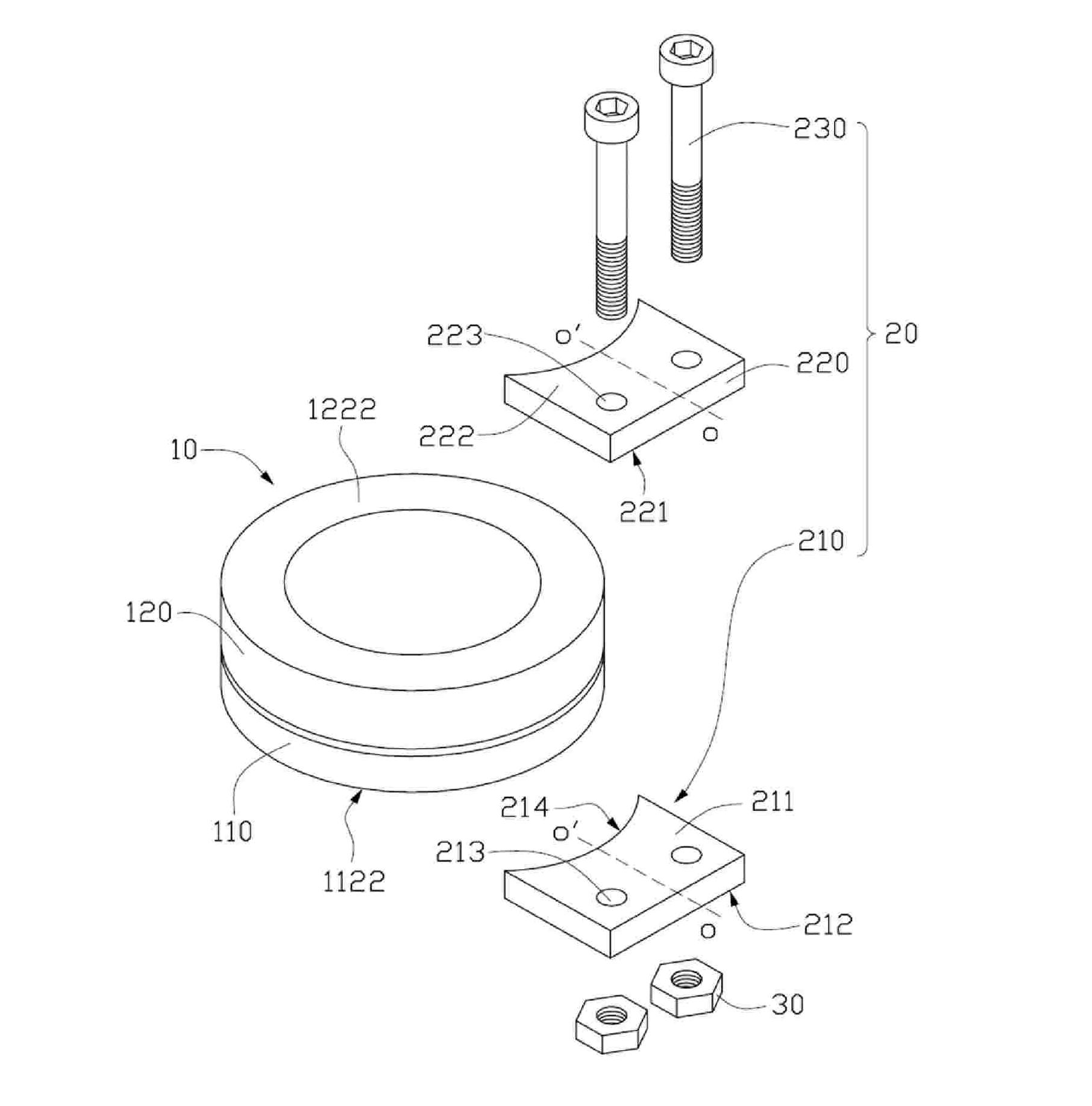

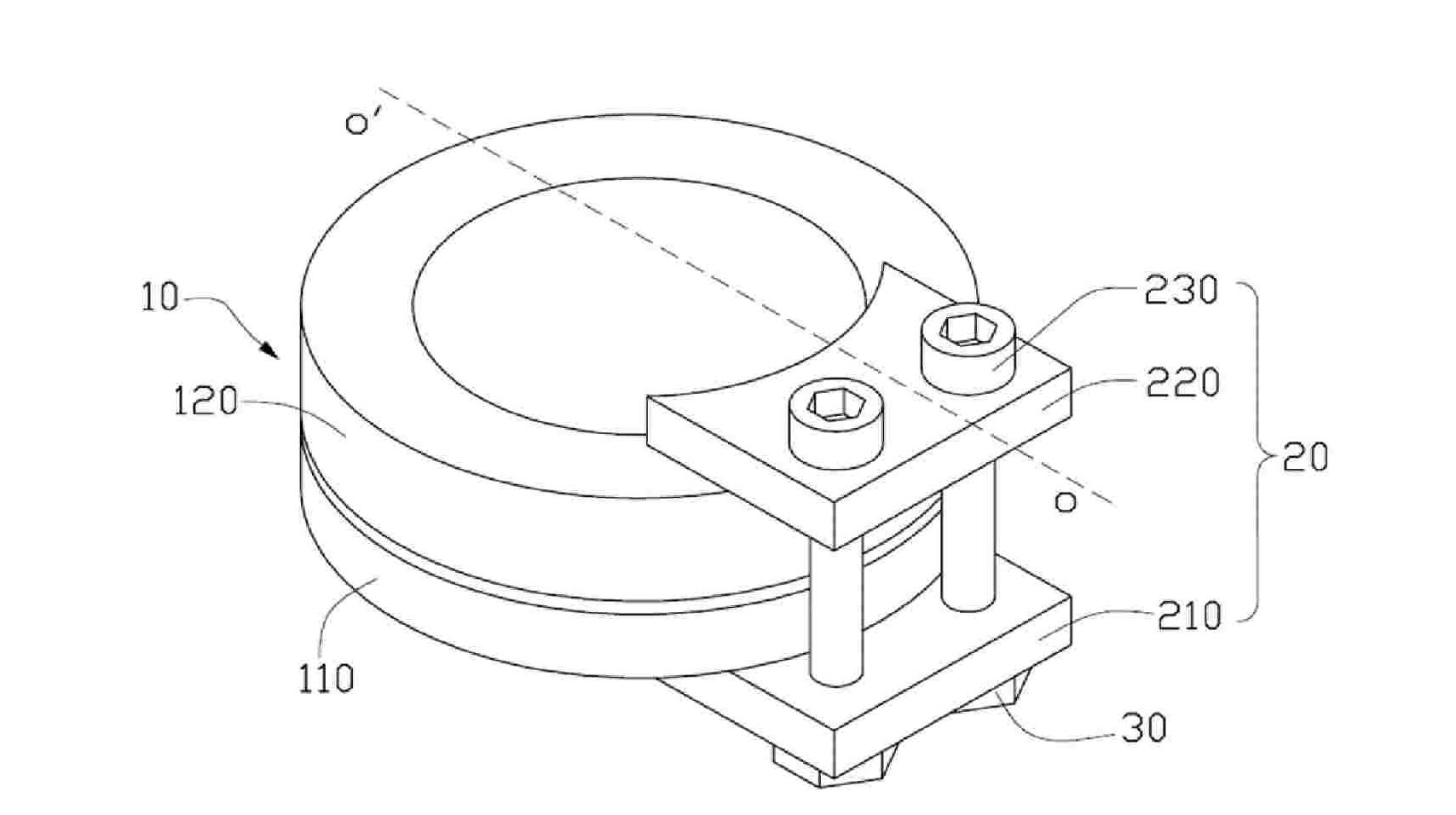

[0018] see Figure 1 to Figure 4 , which illustrates the testing process of the method for testing lens module assembly components provided by the embodiment of the technical solution. It includes the following steps:

[0019] In the first step, the lens module component group 10 to be tested is provided.

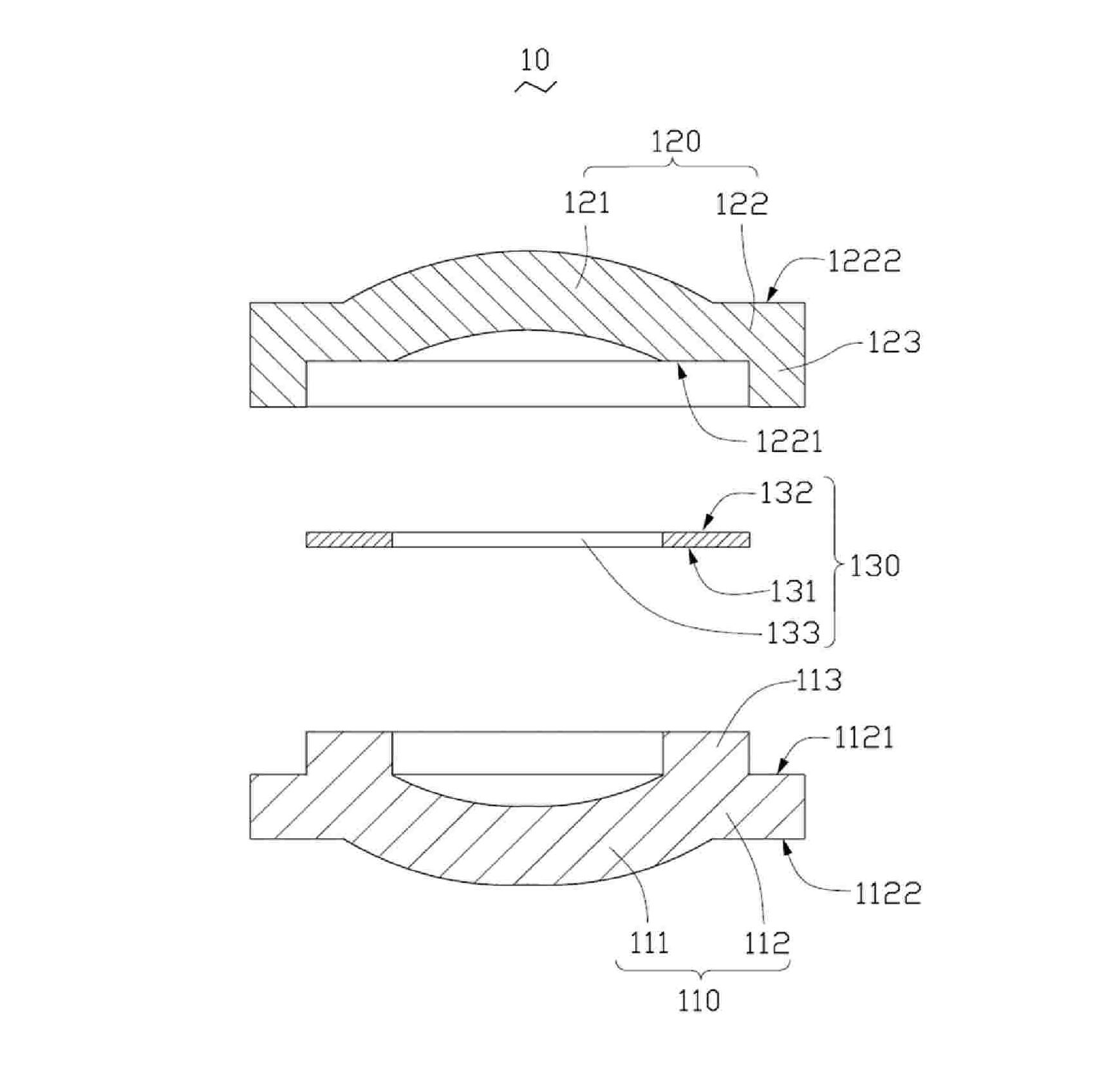

[0020] see figure 1 , the lens module component group 10 to be tested provided by the embodiment of the technical solution, which includes at least two components to be assembled formed by an injection machine, which are used to cooperate and fix each other during testing. Each element in the lens module element group 10 may be formed in the same mold or in different mold cavities of different moulds. Considering different designs of lens modules, the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap