Hydraulic cylinder with throttling buffer mechanism

The technology of a buffer mechanism and a hydraulic cylinder, which is applied in the field of hydraulic cylinders, can solve the problems of complex structure and high assembly precision of the buffer hydraulic cylinder, and achieve the effects of simple structure, improved efficiency and good buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

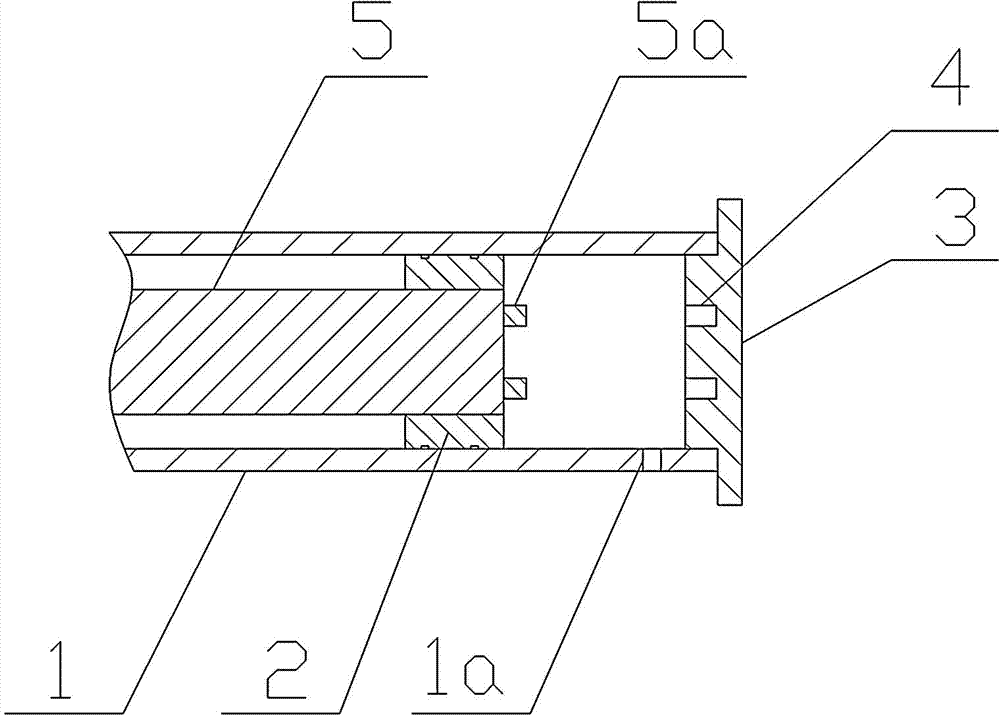

[0016] Such as figure 1 As shown, a hydraulic cylinder with a throttling buffer mechanism provided by the present invention includes a cylinder body 1, an oil injection hole 1a is arranged on one side of the cylinder body, a piston rod 5 is arranged in the inner cavity of the cylinder body, and a piston rod is provided on the piston rod The piston 2 slidingly fitted with the inner cavity of the cylinder is provided with end caps 3 at both ends of the cylinder, wherein a group of buffer holes 4 are arranged on the cylinder head at one end of the cylinder, and the axial direction of each buffer hole is aligned with the axis of the end cap. Oriented parallel to each other, one end of the piston rod 5 is provided with a set of buffer columns 5a, and each buffer column 5a is slidably fitted with the corresponding buffer hole 4 respectively.

Embodiment 2

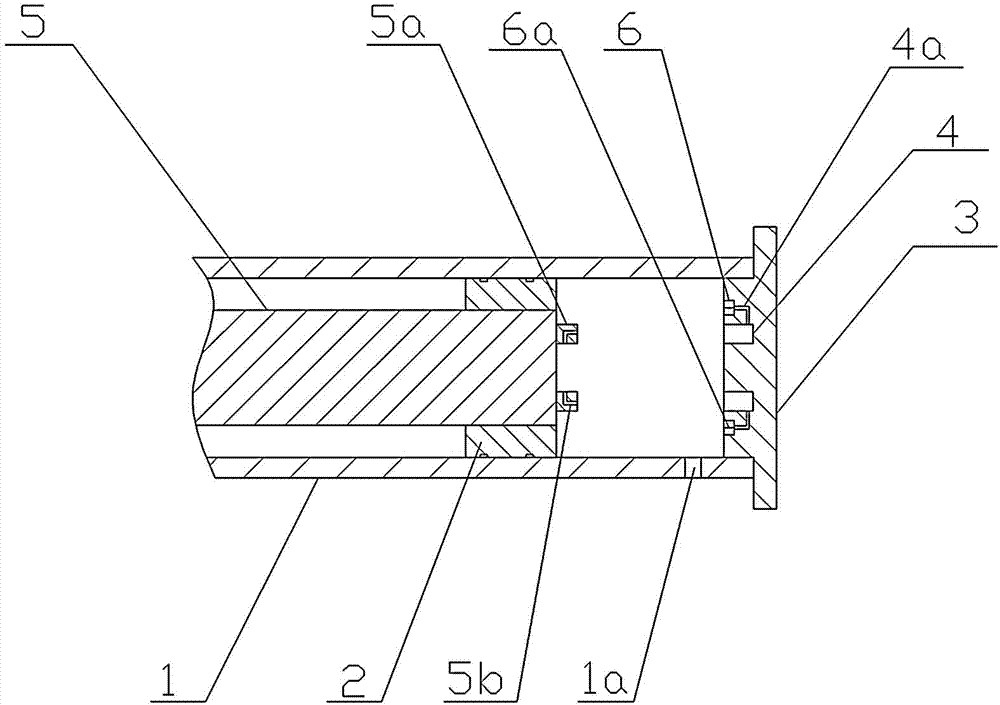

[0018] Such as figure 2 As shown, a hydraulic cylinder with a throttling buffer mechanism provided by the present invention includes a cylinder body 1, an oil injection hole 1a is arranged on one side of the cylinder body, a piston rod 5 is arranged in the inner cavity of the cylinder body, and a piston rod is provided on the piston rod The piston 2 slidingly fitted with the inner cavity of the cylinder is provided with end caps 3 at both ends of the cylinder, wherein a group of buffer holes 4 are arranged on the cylinder head at one end of the cylinder, and the axial direction of each buffer hole is aligned with the axis of the end cap. parallel to each other, a set of throttle nozzles 6 is provided on the cylinder head at one end of the cylinder, each throttle nozzle is provided with a throttle hole 6a, and one end of the throttle hole 6a communicates with the corresponding buffer hole 4 through the return hole 4a One end of the piston rod 5 is provided with a group of buff...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap