Segment Lining and Segment Assembly Method for Rectangular Tunnel with Partition Wall

A segment assembly and tunnel segment technology, which is applied in tunnel lining, tunnel, shaft lining, etc., to achieve the effects of improving economy, reducing bending moment and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

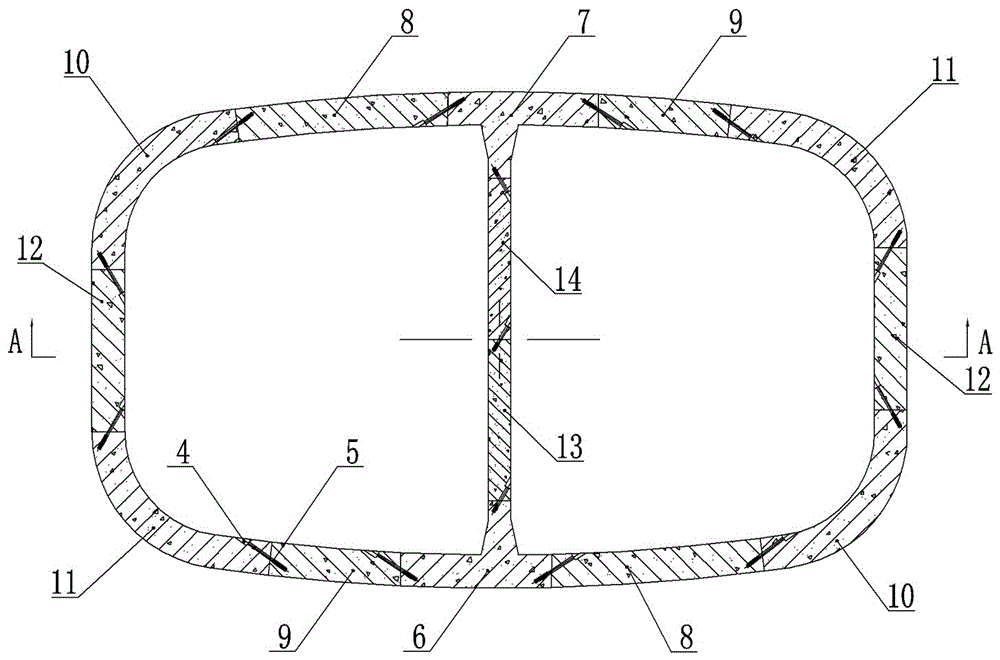

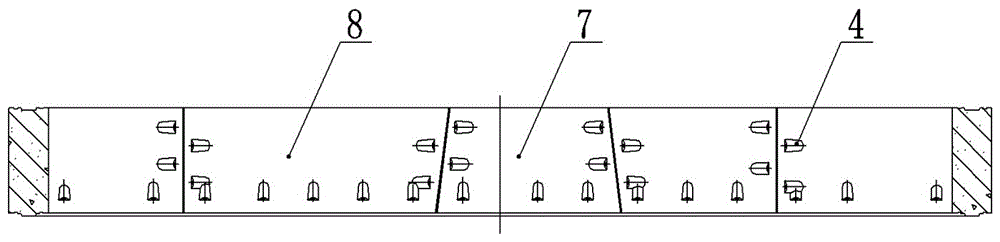

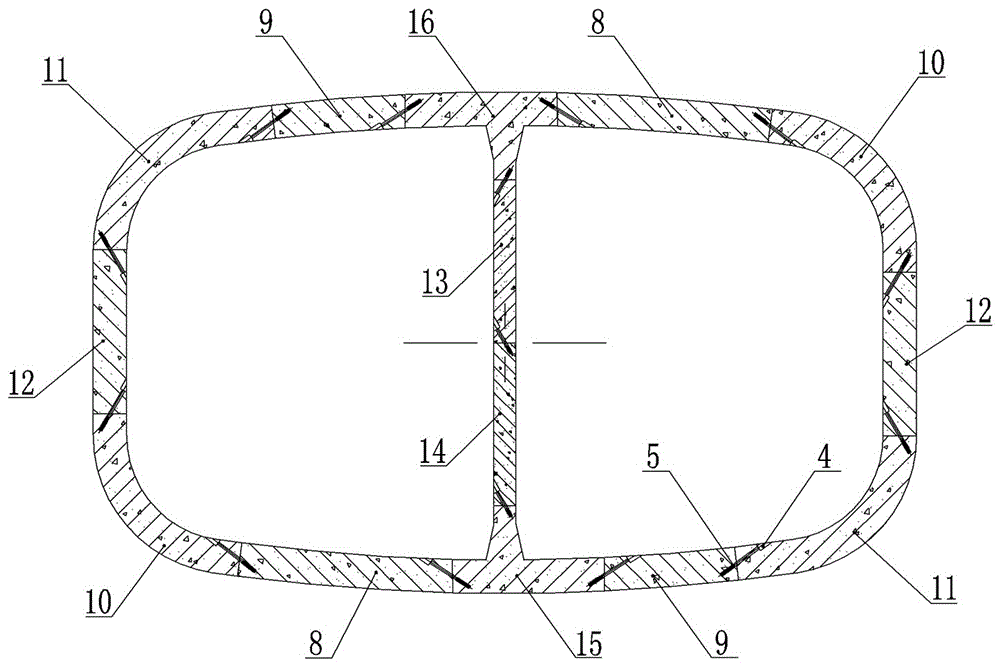

[0032] Embodiment one: see Figure 1-Figure 4 , a rectangular tunnel segment lining for a partition wall, the tunnel section form is a rectangular straight wall arch, the segment lining includes an L-shaped segment ring 1 and an R-shaped segment ring 2, and the L-shaped tube The segment rings 1 and R-shaped segment rings 2 are alternately arranged in a cycle along the direction of the tunnel, and the mid-span areas of the upper and lower arches of the L-shaped segment rings 1 and R-shaped segment rings 2 are provided with intermediate partition walls 3. Both the L-shaped segment ring 1 and the R-shaped segment ring 2 include a plurality of annular segment segments and intermediate wall segments assembled in a ring shape, and the annular segment segments and the intermediate segment segments The segments of the partition wall are made of reinforced concrete. The splicing longitudinal joints of two adjacent segments on the L-shaped segment ring 1 and the splicing longitudinal jo...

Embodiment 2

[0034] Embodiment two: see Figure 1-Figure 3 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The splicing ring seams of segment rings are mortise and tenon joints, wedge joints or tongue and groove joints.

Embodiment 3

[0035] Embodiment three: see Figure 1-Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1 or 2, and the similarities will not be repeated. The difference is that the L-shaped segment ring 1 and the R-shaped segment ring 2 are all about the central axis of the tunnel It has a 180° symmetrical structure, and the L-shaped segment ring 1 includes capping blocks Q7 and T-blocks P6 respectively located in the middle of the upper arch and lower arch of the lining, and assembled in a rectangular ring between the capping block Q7 and the T-block P6 2 pieces of curved arch blocks B8, 2 pieces of curved arch blocks F9, 2 pieces of transition blocks C10, 2 pieces of transition blocks E11 and 2 pieces of straight wall blocks D12, the R-shaped segment ring 2 includes And the capping block S16 and T-shaped block R15 in the middle of the lower arch, and 2 pieces of arch blocks B8, 2 pieces of curved arch blocks F9, and 2 pieces of transition blocks assem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap