Butt welding device and method based on flexible tool and visual positioning

A visual positioning and flexible tooling technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problem of high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

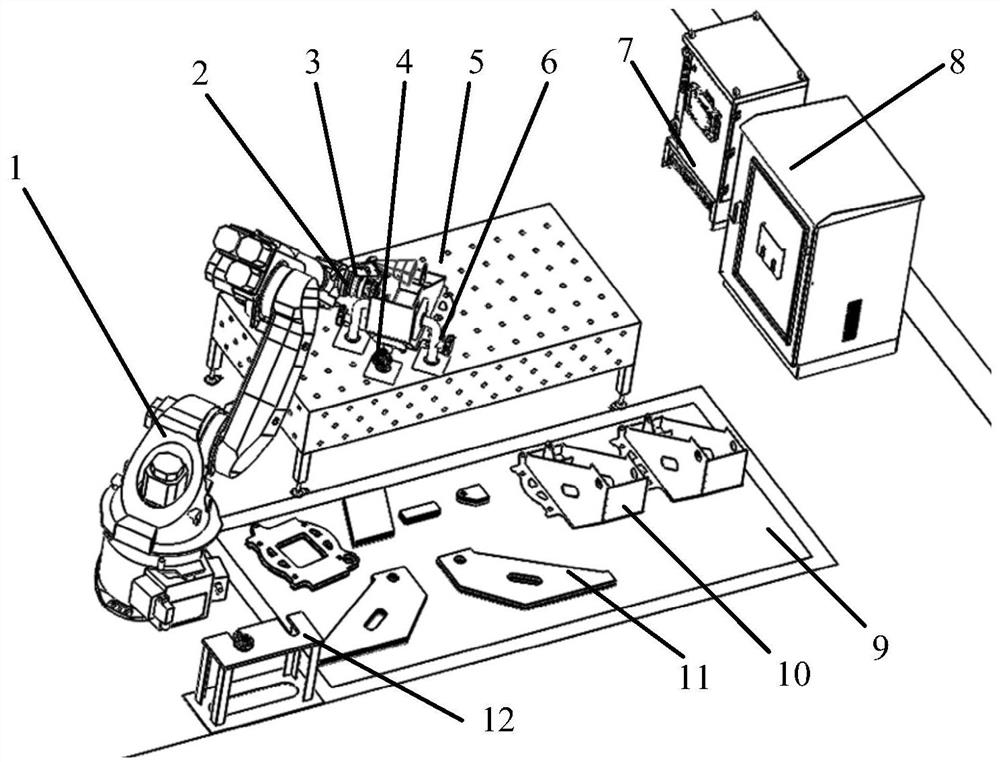

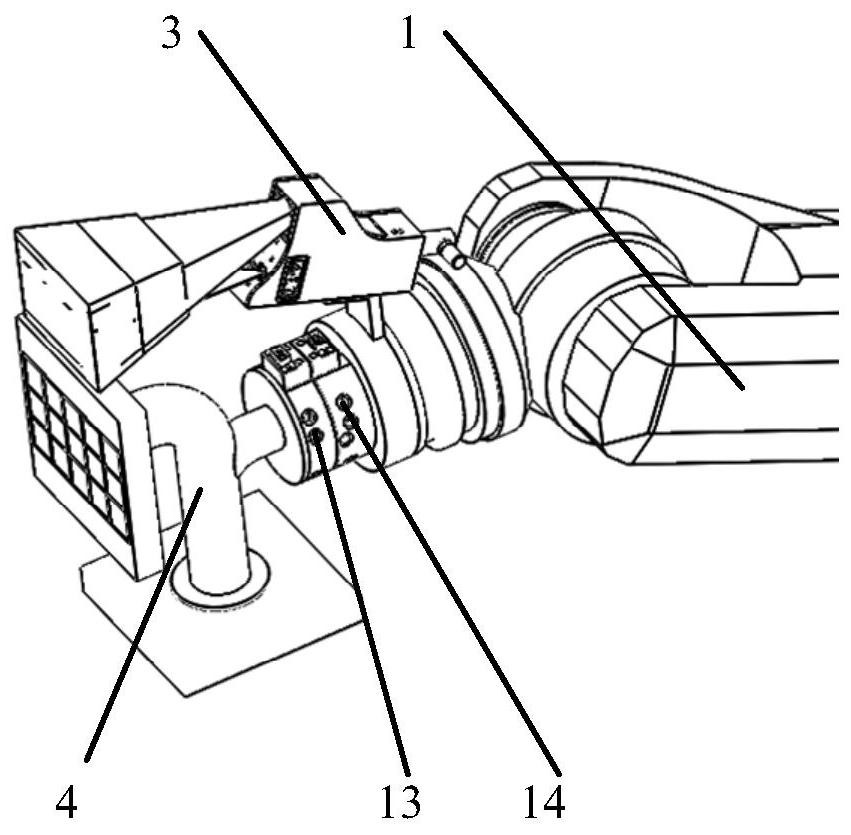

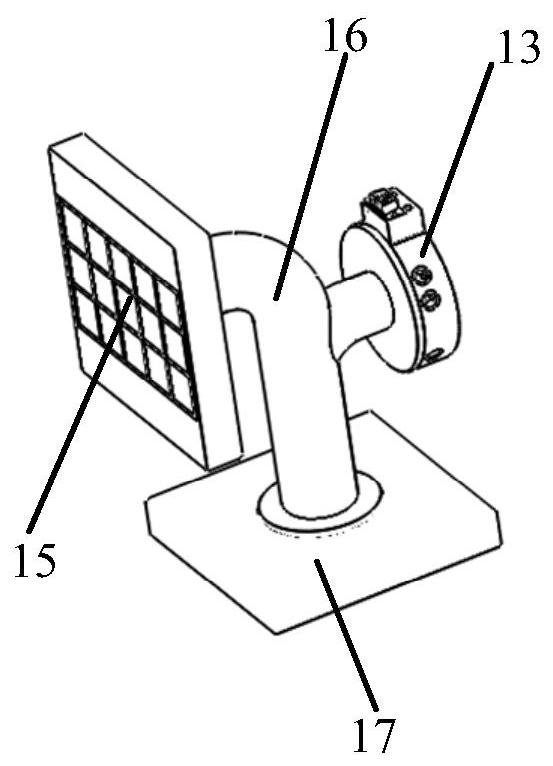

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a tailor welding device based on flexible tooling and visual positioning, including a multi-degree-of-freedom robot arm 1, a pick-up tailor welding tool 2, a vision unit 3, a positioning group matching tool II 4, and a welding platform 5 , Positioning group tooling I6, robotic arm controller 7, electric controller 8, loading and unloading area 9, finished welded structural parts 10, welded structural parts 11 and quick change system bracket 12.

[0041] The multi-degree-of-freedom manipulator 1 is connected with the positioning group pair tooling and the vision unit 3. The multi-degree-of-freedom manipulato...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap