Improved aluminum casting airtightness detection device and detection method thereof

A technology of air tightness detection and detection device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, by measuring the acceleration and deceleration rate of fluid, etc. reference opinions and other issues to achieve the effect of reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions of the present invention will be apparent from the embodiments of the present invention, which is apparent from the embodiments of the present invention, and is merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

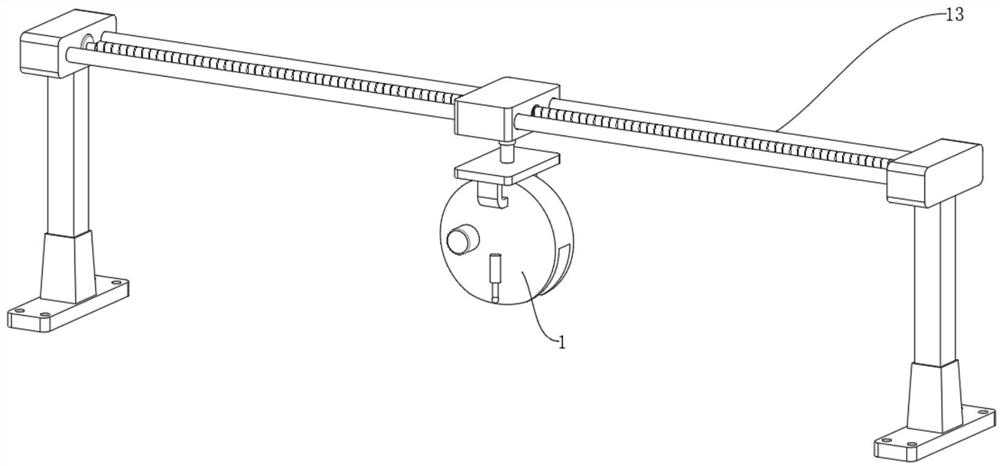

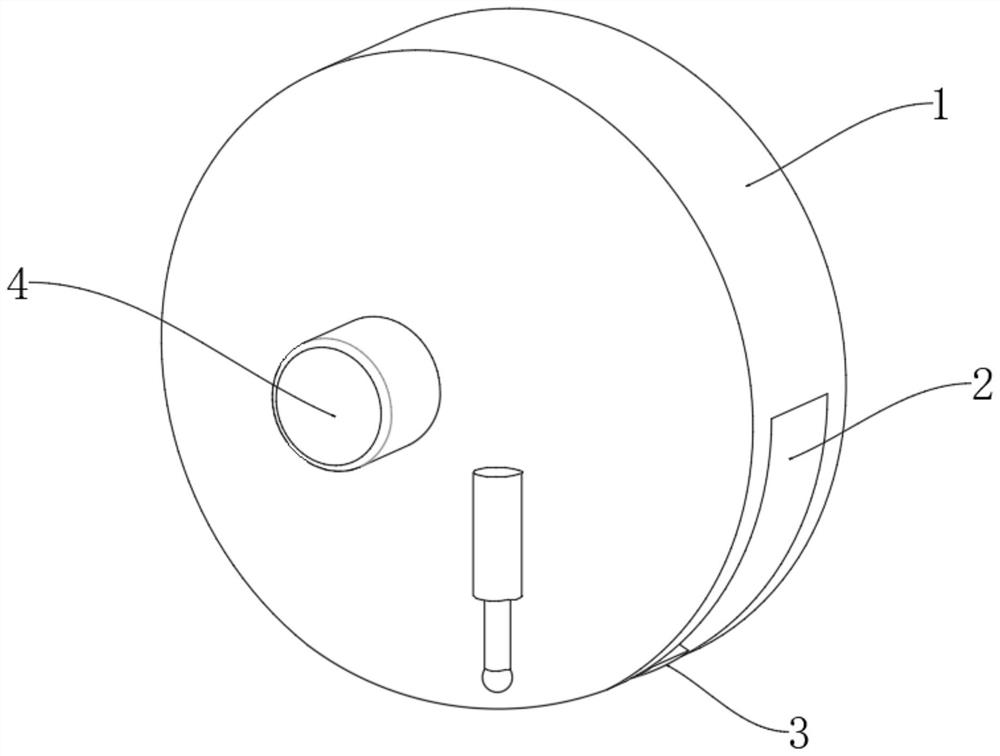

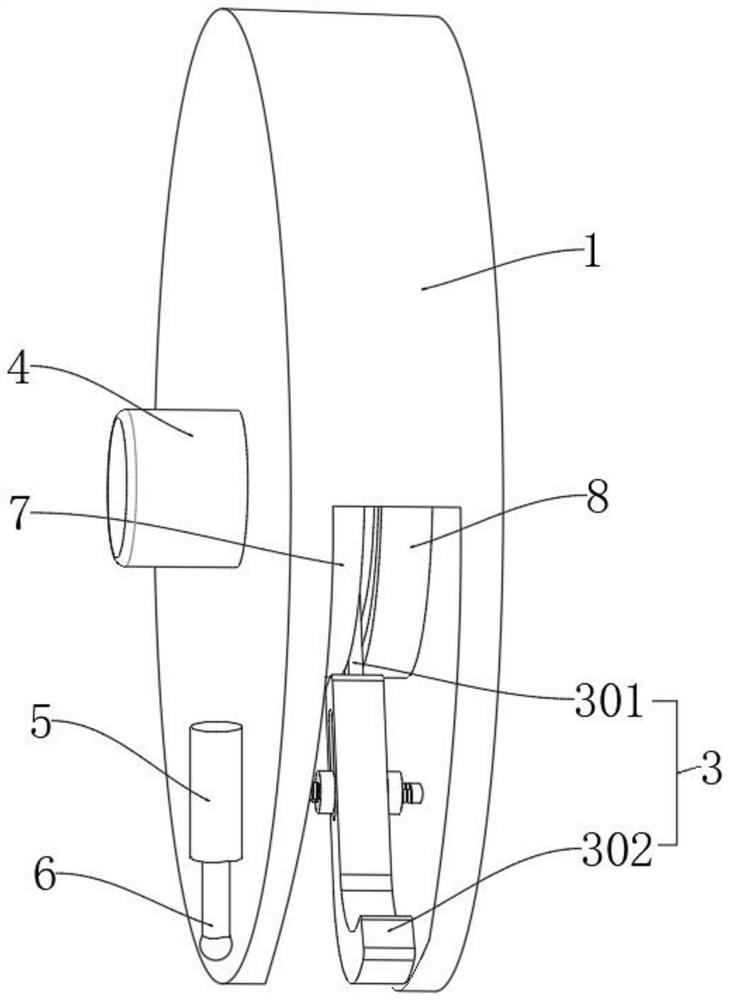

[0032] See Figures 1 to 7 The present invention provides a technical solution: an improved aluminum casting airtight detecting device including a workpiece clamping device, a leak detecting device, and a blowing device for clamping the fixed aluminum casting workpiece. (, Such as the cylinder shell), and the workpiece can be sewed, and the commonly used workpiece clamping means, such as a pair of opposing cylinders, through the cylinders on both sides to fix the workpiece. The blowing device is for blowing into ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap