Intelligent operation and maintenance system of electric equipment

A technology for operation and maintenance systems and power equipment, applied in the direction of circuit devices, electrical components, etc., can solve problems such as prone to errors, failure to monitor equipment data parameters, complex data processing process, etc., and achieve the effect of reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

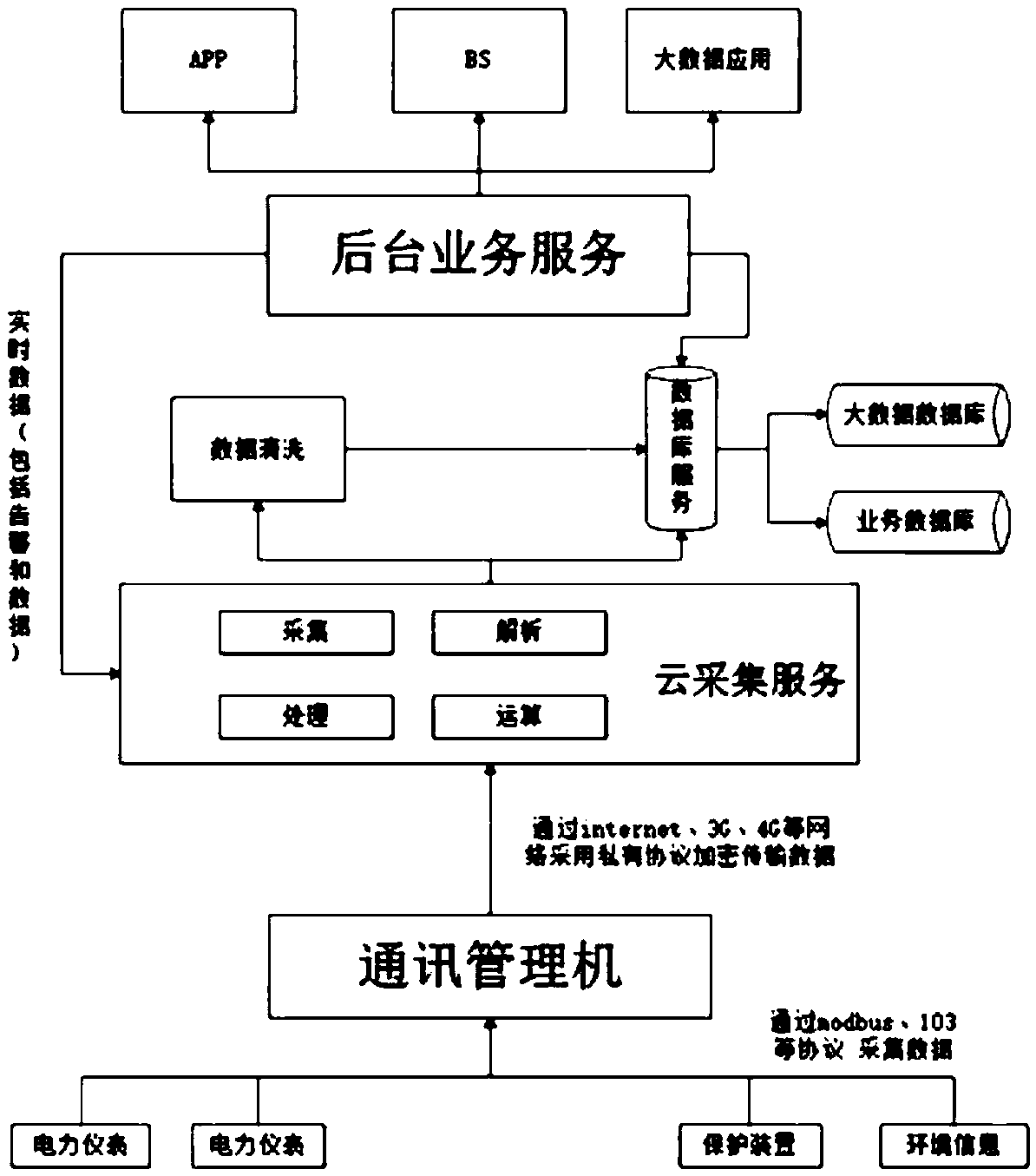

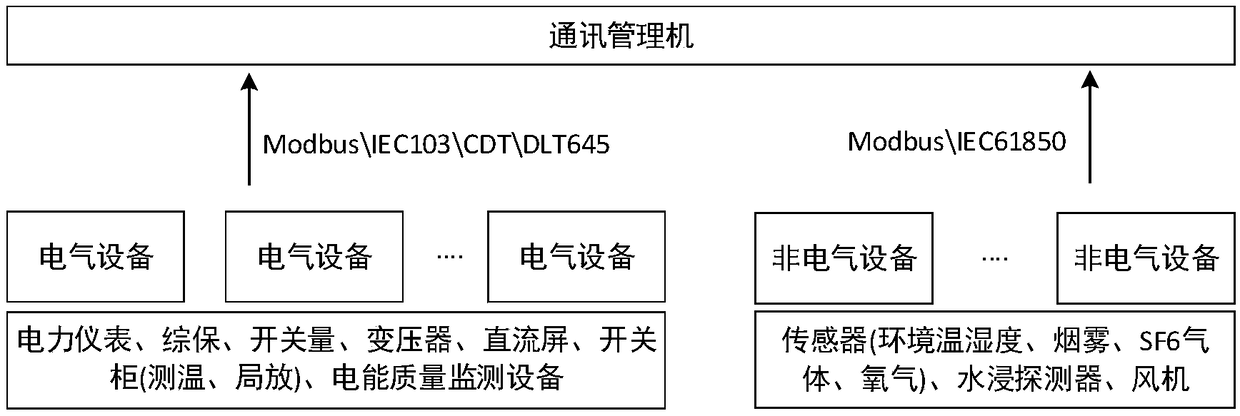

[0031] refer to figure 1 , for this reason, the present invention discloses an intelligent operation and maintenance system for power equipment,

[0032] The encoding module is used to encode the equipment according to the set encoding rules according to the different types of equipment and the basic functions of the equipment, and incrementally encode the monitoring and sensing modules supporting the equipment;

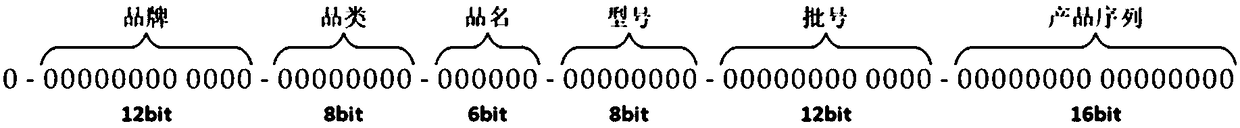

[0033] refer to figure 2 , device coding is divided into the following six aspects:

[0034] Brand, category, product name, model, batch number, product sequence

[0035] Intelligent operation and maintenance equipment coding is divided into the following seven aspects:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com