Four-axis length variable adjustable square tube machine based on press roller dislocation design

A technology of dislocation design and shaft length, which is applied in the field of four-axis length variable adjustable square tube machines, can solve problems such as disassembly collisions, production efficiency reduction, and pressure roller damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

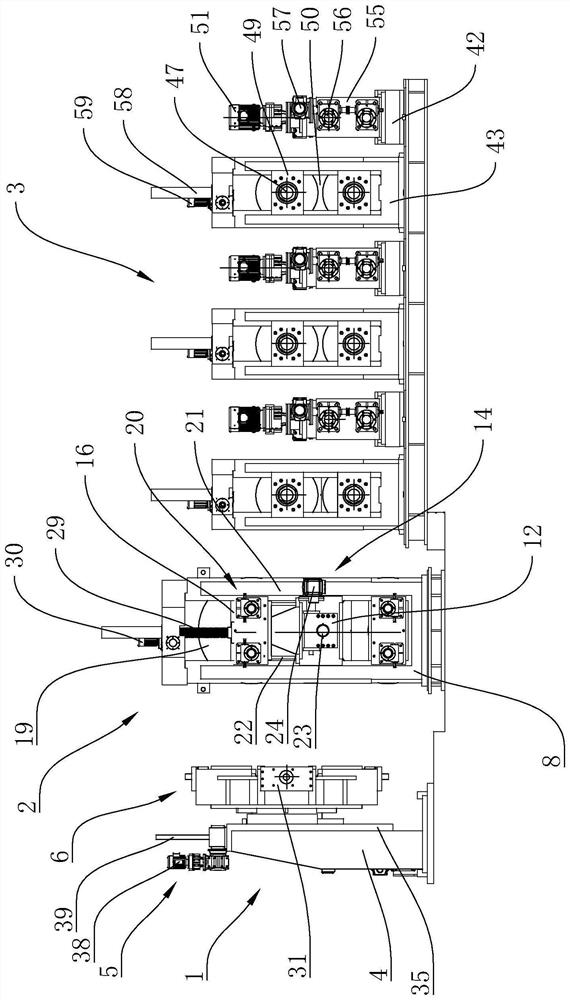

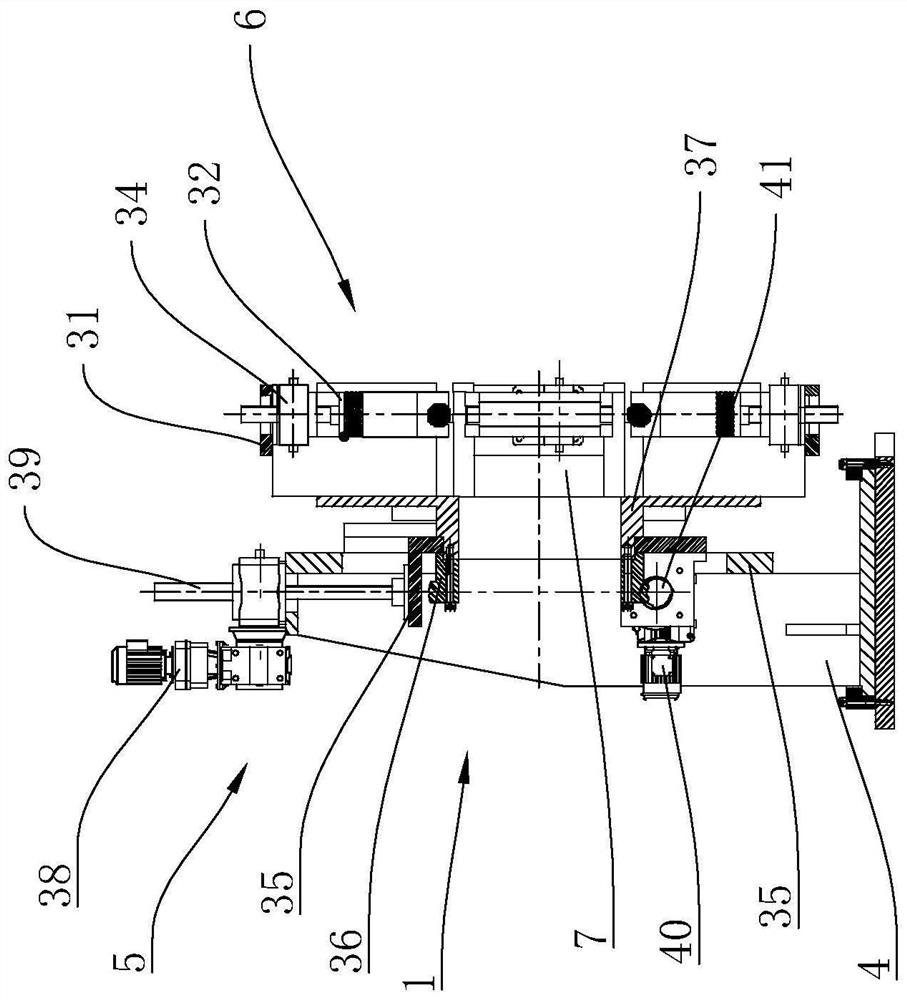

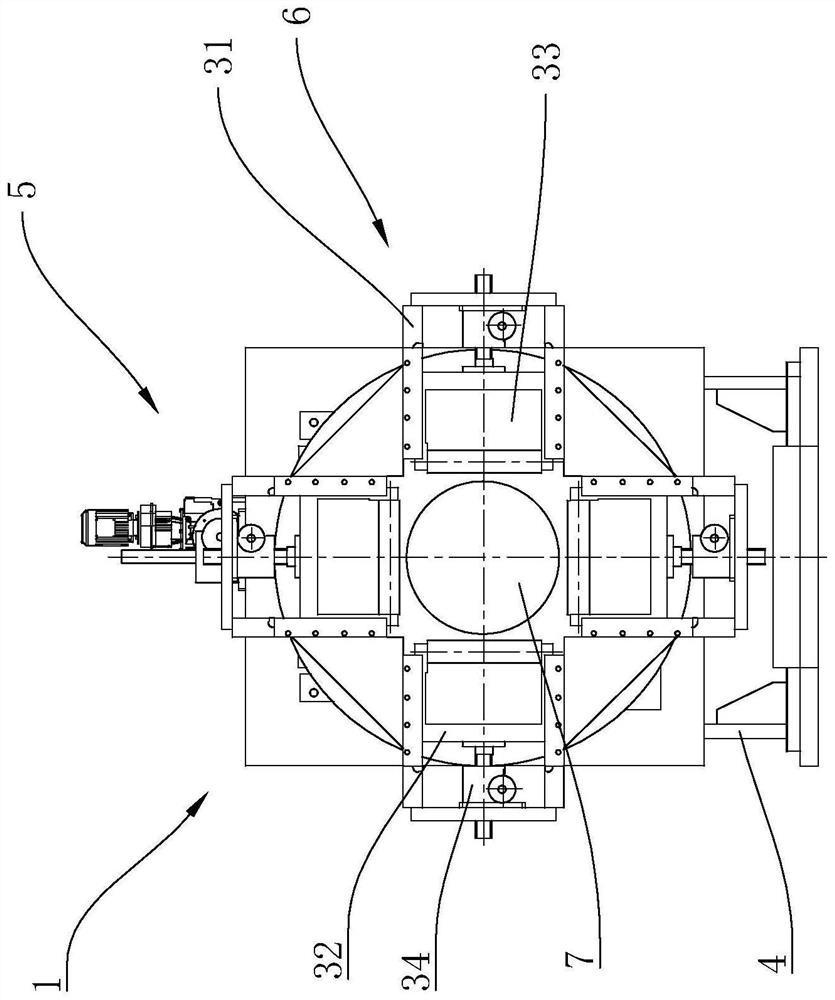

[0030] like Figure 1-Figure 4 As shown, a four-axis length-variable adjustable square pipe machine based on the dislocation design of the pressure rollers includes a straightening device 1, an extrusion device 2 and a dislocation sizing device 3, and the straightening device 1 includes a straightening seat 4 , the straightening seat 4 is connected with four straightening roller assemblies 6 arranged in the circumferential direction through a position adjustment structure 5, and there is a circular tube straightening channel 7 between the four straightening roller assemblies 6, and the The extrusion device 2 includes an extrusion frame 8, and the extrusion frame 8 is provided with two multi-directional adjustable horizontal pressure roller assemblies 9 and two multi-directional adjustable vertical pressure roller assemblies 10, Two horizontal press roller assemblies 9 and two vertical press roller assemblies 10 are combined to form an extruded channel 11 that is compatible wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com