Machining method for clamping groove of spoke and spoke

A processing method and technology of slots, which are applied in the processing method of slots and the field of spokes, can solve the problems of difficulty in processing slots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

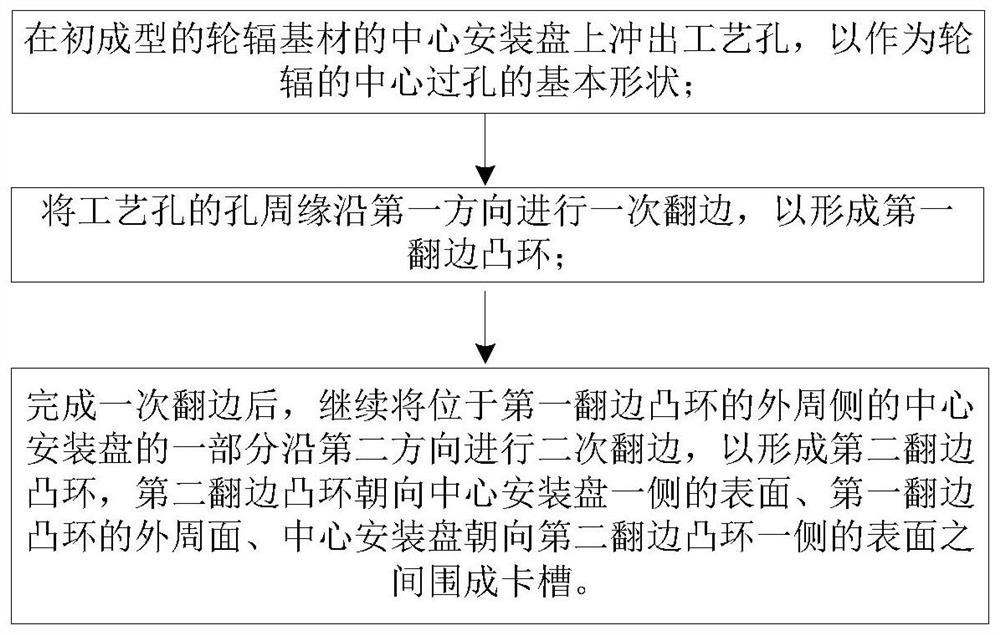

[0035] Such as Figure 1 to Figure 4 As shown, the processing method of the card slot of the spoke, the card slot 1 is used to clamp the decorative cover, including punching out the process hole 12 on the center mounting plate 11 of the initially formed wheel spoke base material 10, as the central via hole of the wheel spoke Basic shape; the hole periphery of the process hole 12 is flanged once along the first direction to form the first flanging convex ring 13; A part of the mounting disc 11 is subjected to secondary flanging along the second direction to form a second flanging protruding ring 14, the surface of the second flanging protruding ring 14 facing the central mounting disc 11 side, the surface of the first flanging protruding ring 13 A slot 1 is formed between the outer peripheral surface and the surface of the central mounting plate 11 facing the second flanged ring 14 .

[0036] It should be noted that, compared with the existing groove 1 formed by turning, the p...

Embodiment 2

[0042] Such as Figure 5 to Figure 11 As shown, the processing method of the slot of the spoke, the slot 1 is used to clamp the decorative cover, including punching out the process hole 12 on the initially formed spoke base material 10, as the basic shape of the central via hole of the spoke; Press the card groove 1 on the first surface of the hole periphery of the hole 12; heat the preset time T at the position where the hole periphery of the process hole 12 has the card groove 1 by the heating device 2; the hole periphery of the process hole 12 after heating Flanging is performed along the axial direction of the process hole 12 so that the card slot 1 is located on the outer peripheral side of the process hole 12 .

[0043] It should be noted that, compared with the existing groove 1 formed by turning, the processing method of the above-mentioned groove of the spoke is much less difficult to process, and can also avoid cracking at the flange as much as possible.

[0044] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com